Archive, Spra – Ransburg Evolver 202 Solvent A11918-XXX User Manual

Page 27

AA-07-01

2 2

2 2

2 2

2 2

2 2

Evolver 202 Robotic Atomizers - Installation

SPRA

SPRA

SPRA

SPRA

SPRAY

Y

Y

Y

Y / BELL

/ BELL

/ BELL

/ BELL

/ BELL

APPLICA

APPLICA

APPLICA

APPLICA

APPLICAT

T

T

T

TOR

OR

OR

OR

OR

TRIGGERING

TRIGGERING

TRIGGERING

TRIGGERING

TRIGGERING

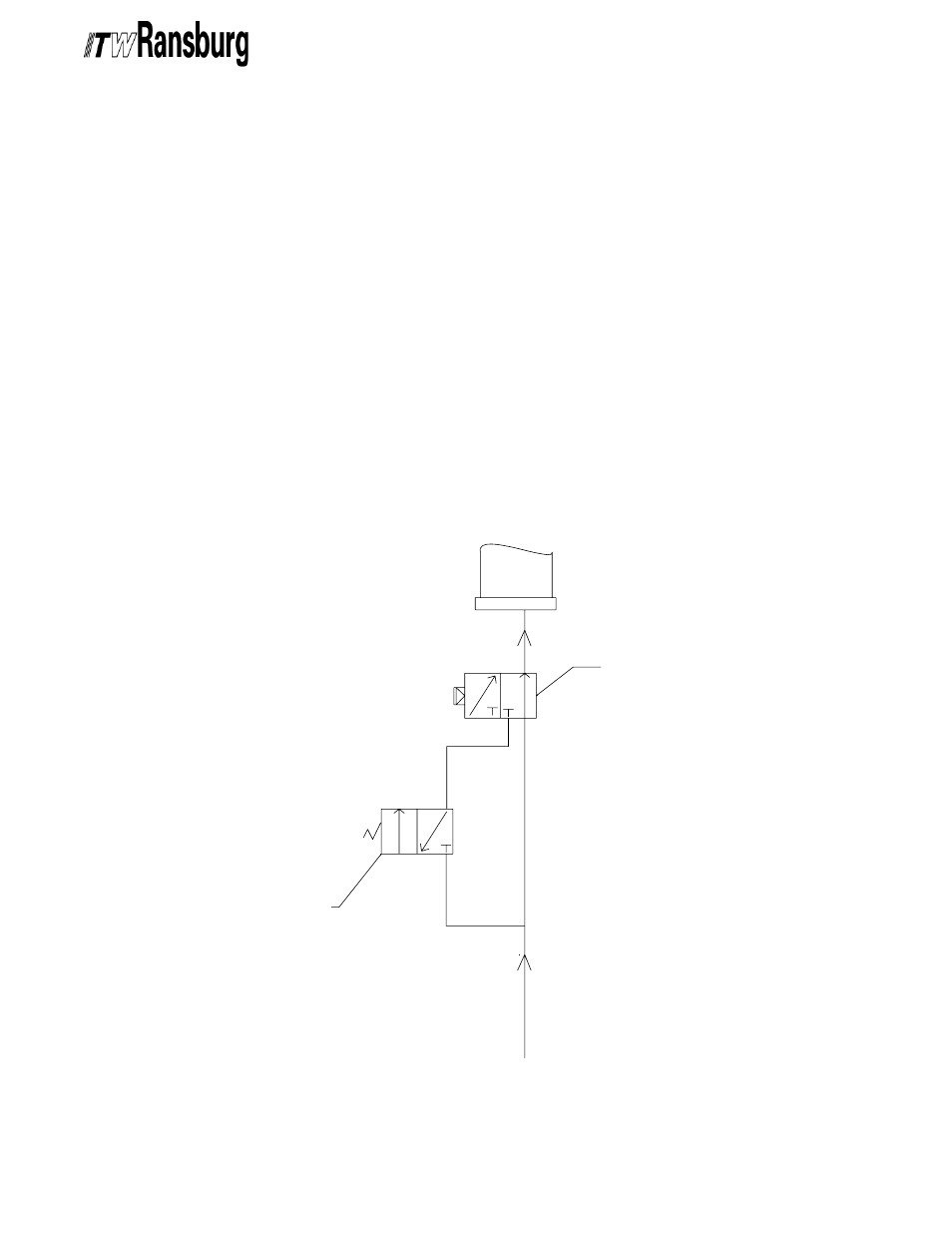

If you are currently using an RMA-202 bell

applicator system and want to add the Evolver 202

spray applicator system to spray using the same

tubing bundle, a simple conversion must be made

in order to allow for switching between spray and

bell applicators. Figure 7 shows the recommended

system that should be placed in the bearing air line

between the main air input and the robot manifold

plate. It is suggested that this circuit be placed on

the robot arm. This system should also be used

when the user is implementing the Evolver 202

spray applicator system and plans to use RMA-

202 bell applicators as well.

Figure 7: Conversion Schematic

Figure 7: Conversion Schematic

Figure 7: Conversion Schematic

Figure 7: Conversion Schematic

Figure 7: Conversion Schematic

In Figure 7, the trigger solenoid must be an

electronically activated, normally closed valve

with exhaust, or a 3-way valve, with 100 psi max.,

24VDC. Typically this solenoid already exists in

the robot arm and can be used in this circuit. The

spray applicator trigger/bearing air select valve

must be a pneumatically activated, normally open

solenoid. A suggested solenoid is ITW P/N 11678-

01. An additional solenoid must be used to activate

the P1T (Paint 1 Trigger) or P2T (Paint 2 Trigger)

valves. If any of these solenoids are located inside

a hazardous area, they must be explosion proof.

MAIN AIR LINE

SPRAY APPLICATOR SIDE

BELL APPLICATOR SIDE

TRIGGER

SOLENOID

SPRAY APPLICATOR TRIGGER/

BEARING AIR SELECT

BEARING AIR LINE

ARCHIVE