Troubleshooting guide, Archive, Evolver 202 robotic atomizers - maintenance – Ransburg Evolver 202 Solvent A11918-XXX User Manual

Page 55

AA-07-01

5 0

5 0

5 0

5 0

5 0

Evolver 202 Robotic Atomizers - Maintenance

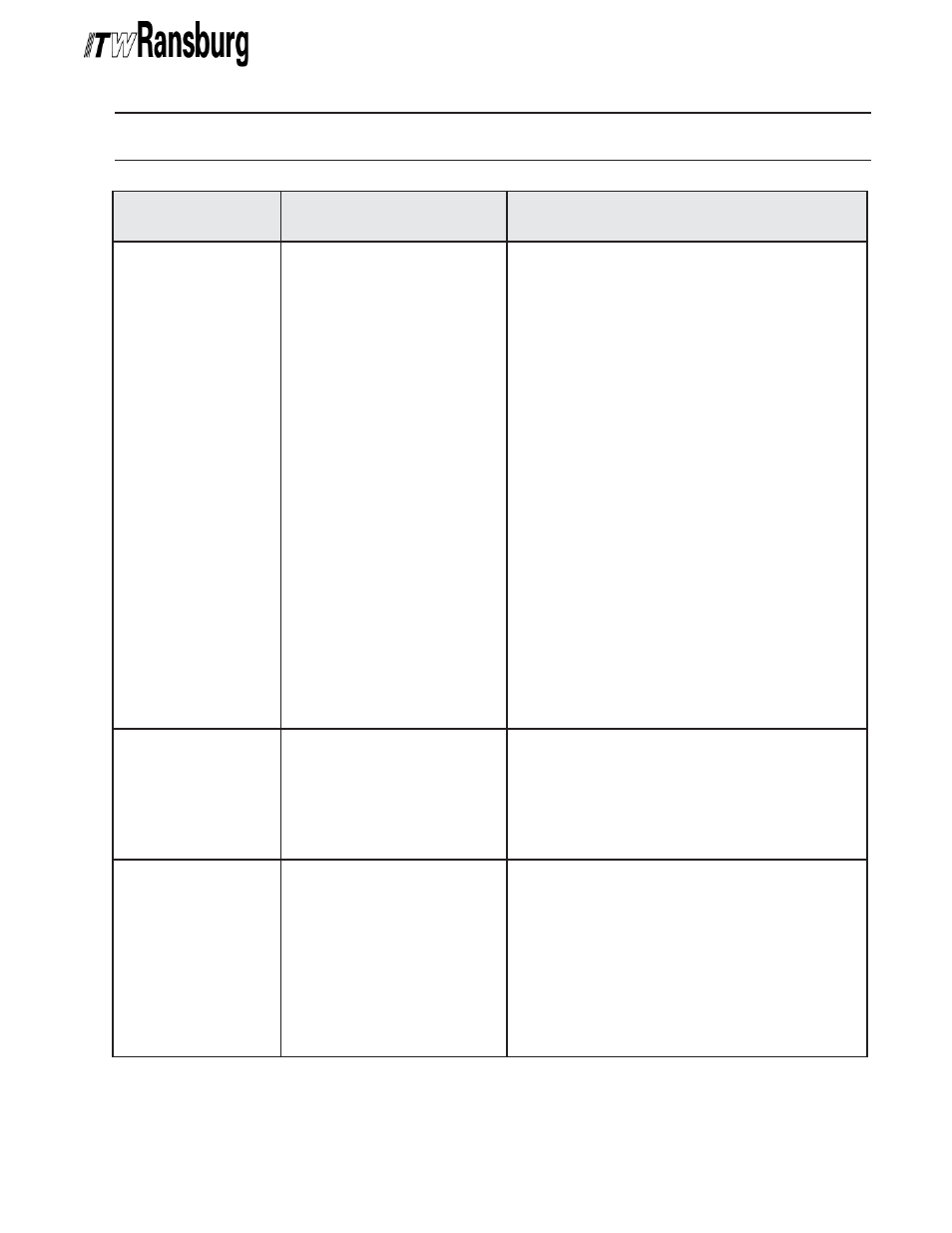

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

Note: A test station to bench test the applicator off-line will speed the Troubleshooting process.

General Problem

General Problem

General Problem

General Problem

General Problem

Possible Causes

Possible Causes

Possible Causes

Possible Causes

Possible Causes

Corrective Action

Corrective Action

Corrective Action

Corrective Action

Corrective Action

Fluid Does Not

Fluid Does Not

Fluid Does Not

Fluid Does Not

Fluid Does Not

Turn On

Turn On

Turn On

Turn On

Turn On

No Fan or

No Fan or

No Fan or

No Fan or

No Fan or

Atomization Air

Atomization Air

Atomization Air

Atomization Air

Atomization Air

Pressure At the

Pressure At the

Pressure At the

Pressure At the

Pressure At the

Air Cap

Air Cap

Air Cap

Air Cap

Air Cap

Excessive

Excessive

Excessive

Excessive

Excessive

Current or Loss of

Current or Loss of

Current or Loss of

Current or Loss of

Current or Loss of

High Voltage

High Voltage

High Voltage

High Voltage

High Voltage

1. Trigger pilot regulator has

not been set to a minimum

of 70 psig

2. The green air tube possibly

left disconnected during re-

assembly

3. Green tube leading from

the source to the applicator

mounting plate is pinched or

broken

4. Piston seal within the appli-

cator spray head is not in

place or there is an ex-

tremely tight fit between the

seal and the cylinder wall

5. P1T or P2T not actuated

6. Paint trigger (BA/PT) not

actuated

1. Low trigger pilot air pres-

sure (70 psi min. required)

2. Air tubes 79134-00 are not

installed properly.

3. Blue or gray 3/8" OD

tube is cut or pinched

1. Metallic particle alignment

in coiled tube

2. Fluid leaks inside

3. Fluid coil pin-holed

4. Exterior of applicator

contaminated

1. Increase to 70 psig minimum.

2. Reconnect tubing.

3. Check the tubing for kinks or damage. Re-

place if worn or damaged.

4a. Make sure that the seal is in the proper posi-

tion and/or lubricate with a small amount of

petroleum jelly.

4b. O-rings left out of small Ø tie rods.

4c. O-ring missing between mounting block and

upper manifold.

4d. O-ring missing between mounting block and

replaceable head.

5. Make sure P1T or P2T (whichever paint line is

in use) is activated. Both P1T or P2T and BA/

PT (paint trigger) must be activated to trigger

the applicator on.

6. Make sure paint trigger (BA/PT) is actuated.

Both P1T or P2T and BA/PT must be actuated

to trigger the applicator on.

1. Increase pressure.

2. Reinstall and tighten as required.

3. Examine, repair as required.

1. Start fluid flow before turning voltage on.

2. Repair/replace fittings and/or coiled fluid tube

as required.

3. Replace coil as required.

4. Clean with non-polar solvent.

(Continued On Next Page)

(Continued On Next Page)

(Continued On Next Page)

(Continued On Next Page)

(Continued On Next Page)

ARCHIVE