Ransburg, Rma-303 dual purge/direct charge - maintenance, Troubleshooting guide (cont.) – Ransburg RMA Dual Purge Direct A12300 User Manual

Page 83

RMA-303 Dual Purge/Direct Charge - Maintenance

78

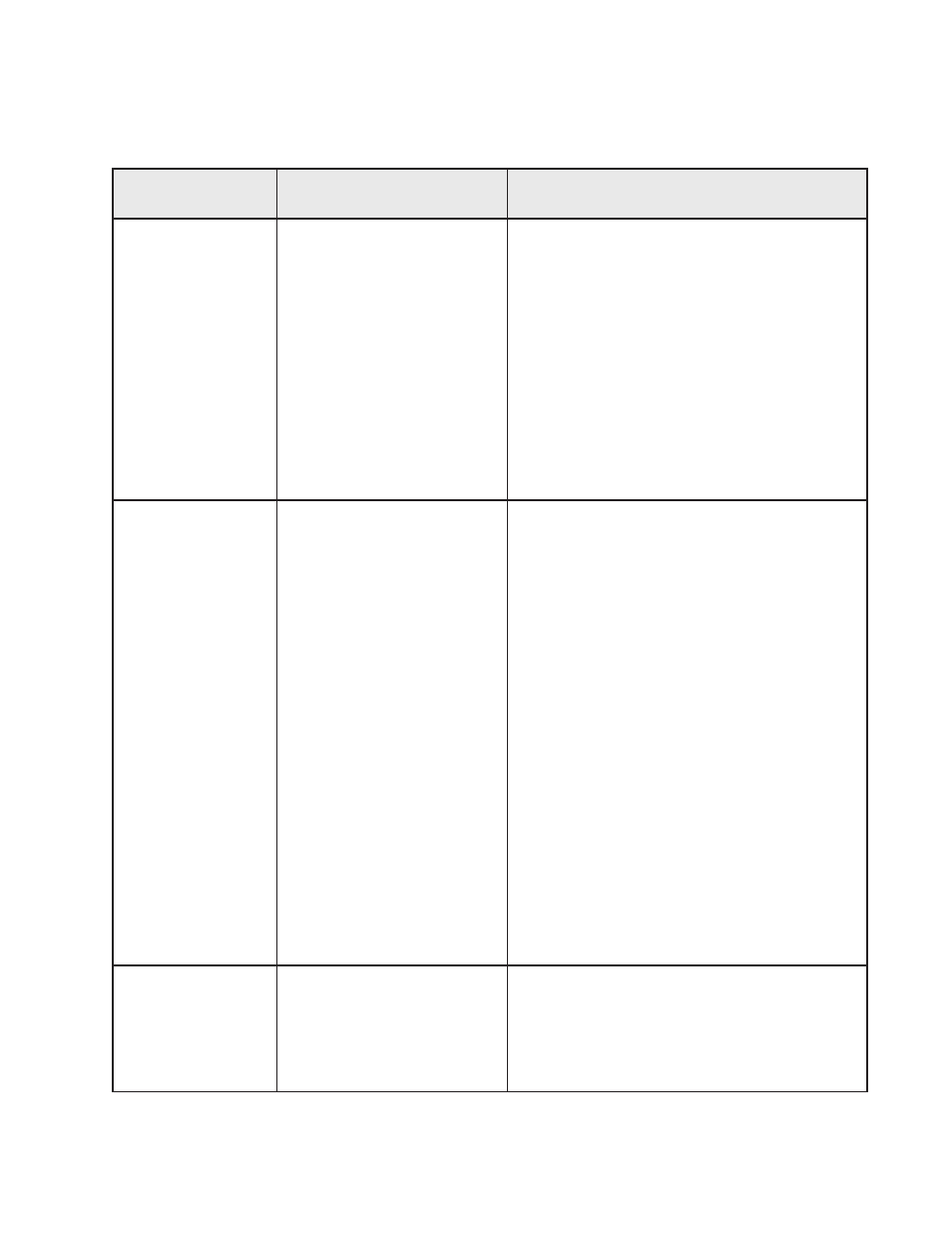

General Problem

Possible Causes

Low or No High

Voltage (Cont.)

Low Transfer

Efficiency (or light

coverage)

No Turbine Air

7. Faulty low voltage connec-

tions (usually indicated by

MicroPak feedback fault

light)

8. Faulty high voltage

connection

9. MicroPak or cascade

failure

10. Improper color change

(i.e., paint or solvent in

dump line)

1. Low or no high voltage

2. Poor grounding of parts

being coated

3. Excessive turbine speed

4. Excessive inner/outer

shaping air

5. Excessive target distance

1. Turbine drive air not

present

2. Bearing air return signal

not present

7. a. Make sure quick disconnection electrical

connection is aligned and clean.

b. Check low voltage connection at cascade.

8. a. Remove cascade and check continuity be-

tween cascade connection and turbine shaft.

9. Refer to "MicroPak" service manual for de-

tailed "Troubleshooting Guide".

10. Optimize color change.

1. Verify high voltage at bell cup edge. Normally,

a high voltage setting of 70-100kV is appropri-

ate for most applications.

2. Verify that parts being coated are properly

grounded (the electrical resistance between

the part and ground must not exceed

1 megohm).

3. For optimum transfer efficiency and spray pat-

tern control, the bell rotational speed should

be set at the minimum required to achieve

proper atomization of the coating material.

4. Shaping air should be set at the minimum

volume required to gently direct the spray

pattern toward the part being coated.

Excessive shaping air will cause some

atomized particles to "blow-by" the part or

bounce back onto the atomizer.

5. The recommended target distance is between

6-12-inches (152.4-304.8 Nm) (see "Target

Distance" in the "Operation" section of this

manual).

1. Verify supply air pressure.

2. a. Verify bearing air return signal.

b. Increase bearing air supply pressure to

90 psig (±10 psig) (620.5 ± 68.9 kPa).

(Continued On Next Page)

Troubleshooting Guide (Cont.)

Ransburg

LN-9263-08.5