Ransburg – Ransburg RMA Dual Purge Direct A12300 User Manual

Page 71

RMA-303 Dual Purge/Direct Charge - Maintenance

66

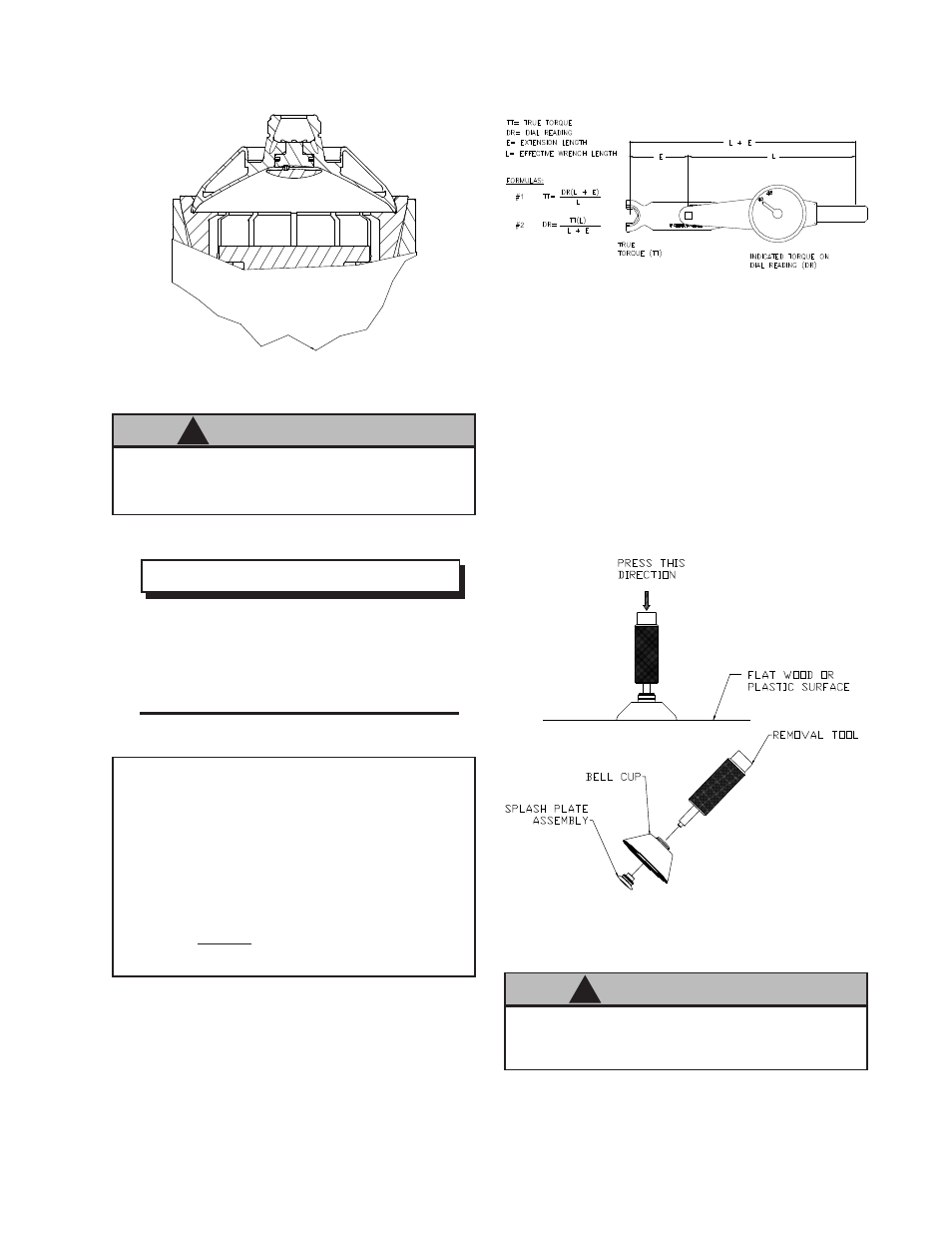

Figure 28: Tool/Bell Cup Engagement

Failure to tighten the bell cup in

place may cause vibration of the appli-

cator and/or premature turbine failure.

C A U T I O N

!

There is a 3-inch center-to-center

distance between the bell cup and the

3/8-inch socket square on the wrench.

This distance must be factored in when

reading the proper torque on the wrench.

NOTE

Figure 29: Effective Length Torque Wrench

Splash Plate Removal

After removing the bell cup from the applicator, put

it on a plastic or wood surface to prevent damage

to the edge of the cup. Using the splash plate

removal tool (A11388-00), insert the small end of

the tool into the end of the splash plate assembly.

Press the splash plate out. It may be necessary

to tap lightly with a hammer.

Figure 30: Shroud Removal

Failure to tighten the bell cup in

place will cause vibration of the applica-

tor and/or premature turbine failure.

C A U T I O N

!

Example: A true torque is desired using

a 9-inch effective length torque wrench.

Wrench offset is 3-inches.

L

=

9-Inches

TT

=

50 lbs•in

E

=

3-Inches

DR is dial reading.

DR = 50 (9)

DR = 37.5 lbs•in

(9 + 3)

Ransburg

LN-9263-08.5