Ransburg, Mounting, Electrical & fiber optic connections – Ransburg RMA Dual Purge Direct A12300 User Manual

Page 41: Fluid connections, Typical installation, Air heater

RMA-303 Dual Purge/Direct Charge - Installation

36

MOUNTING

The RMA-303 is equipped with a quick disconnect

assembly. The quick disconnect feature consists

of a robot plate which is permanently attached

to the robot through a wrist adapter plate, and a

mating bell plate which is a part of the RMA-303

atomizer assembly. The atomizer is secured to

the robot plate with a threaded retaining ring.

ELECTRICAL & FIBER

OPTIC CONNECTIONS

The fiber optic connection is made on the back of

the atomizer's robot plate. The fiber optic cable

comes preassembled with connectors that are

secured in place by set screws tightened from the

side of the robot plate. An adequate ground must

be provided to the mounting plate to ensure that

fluid fittings, etc. are at ground potential.

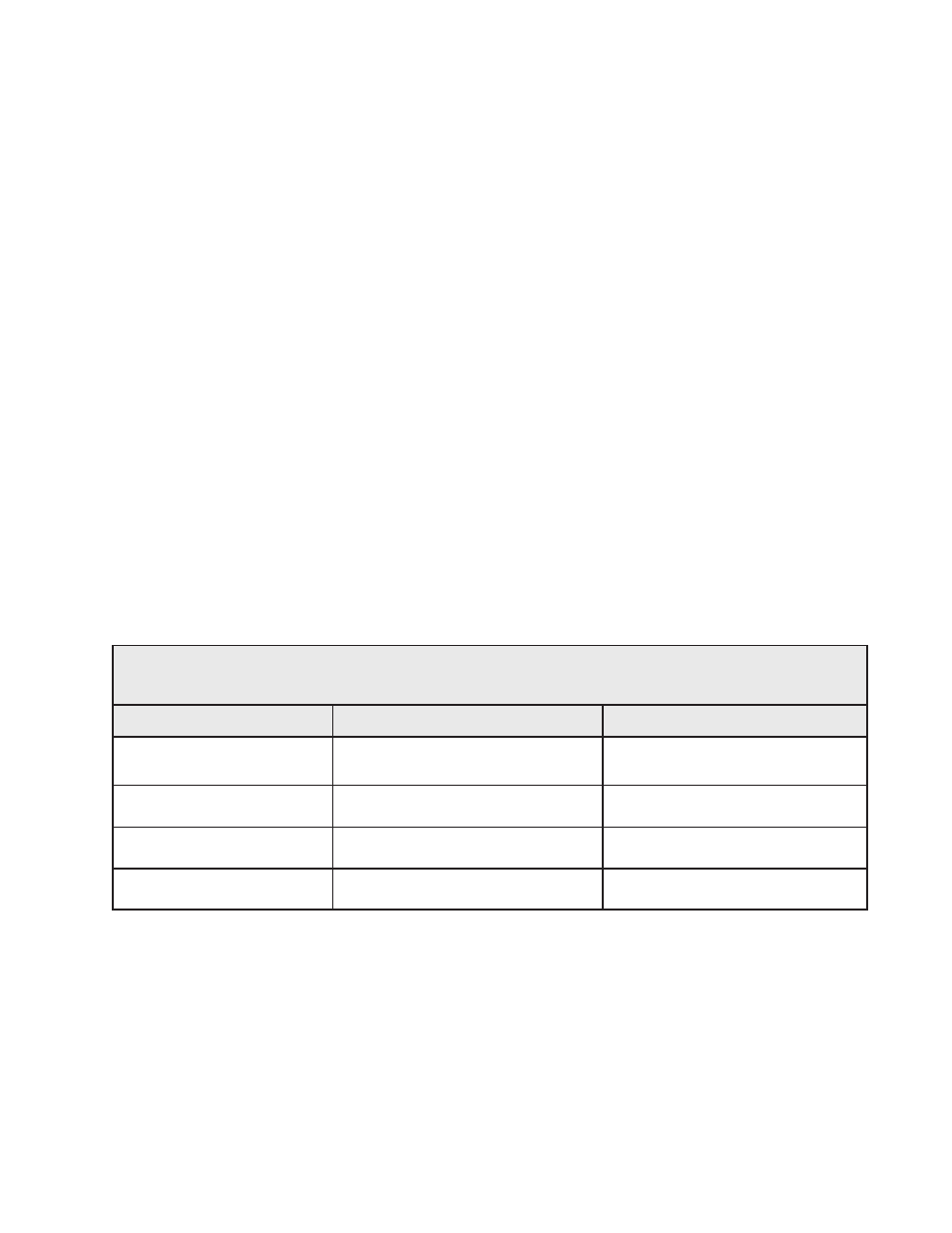

FLUID CONNECTIONS

The paint, solvent, and dump fluid tubing are con-

nected on the back of the robot plate with stainless

steel compression fittings and PFA or nylon tubing.

Fluid tubing requirements are shown in the "Fluid

Tubing Connection Require-ments" below.

TYPICAL INSTALLATION

Figure 8 shows a typical installation of the RMA-

303 and the wiring installation of the applicator

with the MicroPak.

AIR HEATER

Connect air heater to turbine air tubing. Air heater

connection to bearing air is not required.

Ransburg

LN-9263-08.5

5mm ID X 8mm OD / PFA

1/4" ID X 3/8" OD / PFA

4mm ID X 6mm OD / PFA

.170" ID X 1/4" OD, PFA

7mm ID X 10mm OD / Nylon

1/4" ID X 3/8" OD, PFA

4mm ID X 6mm OD / PFA

.170" ID X 1/4" OD, PFA

Paint Line (P)

Solvent Line (SOL)

Dump Line (DL)

Cupwash Solvent (CW)

200 psi max. (1379 kPa)

150 psi max. (1033 kPa)

200 psi max. (1379 kPa)

150 psi max. (1033 kPa)

Fixed Atomizer

Pressure (Maximum)

FLUID TUBING CONNECTION REQUIREMENTS