Ransburg, Equipment grounding & safety recommendations, Rma-303 dual purge/direct charge - installation – Ransburg RMA Dual Purge Direct A12300 User Manual

Page 37

RMA-303 Dual Purge/Direct Charge - Installation

32

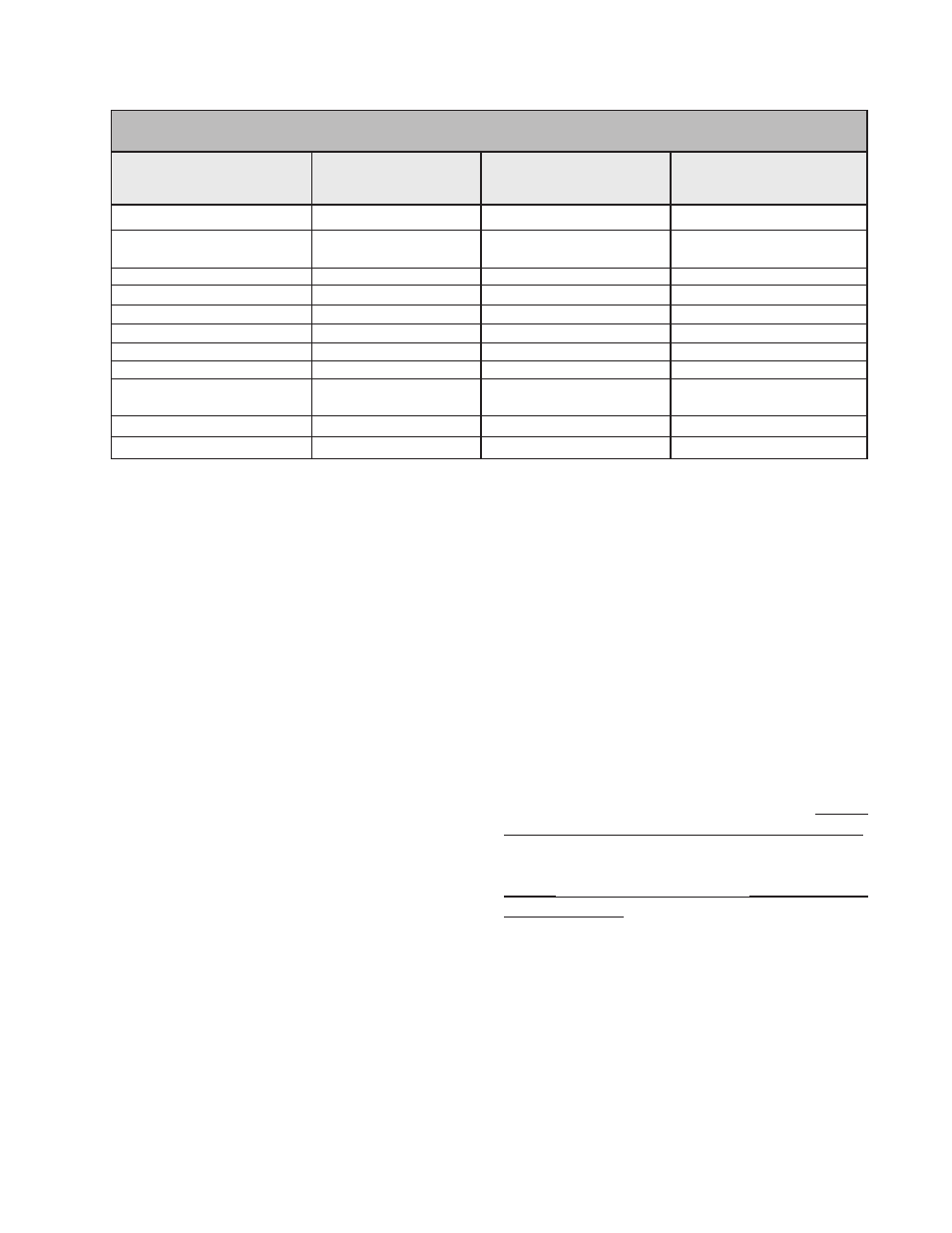

6 X 4mm OD (Yellow)

4mm OD (5/32") (Yellow)

10 X 7mm OD (Natural)

8 X 6mm OD (Gray)

8 X 6mm OD (Blue)

6 X 4mm OD (Orange)

4mm OD (5/32") (Green)

4mm OD (5/32") (Gray)

4mm OD (5/32") (Blue)

4mm (5/32") (Natural)

4mm (5/32") IBlack)

Bearing Air Supply(BA/PT)

Bearing Air Return (BA RTN)

Turbine Air (TA)

Cut-In Air (SAO/FA)

Pattern Control Air (SAI/AA)

Brake Air (BRK)

Paint Valve #1 (P1T)

Dump Valve #1 Control (P1D)

Solvent Valve Control (ST/RP)

Paint Valve #2 Control (P2T)

Dump Valve #2 Control (P2D)

1/4" OD X .170" ID (Yellow)

4mm (5/32") (Yellow)

3/8" OD X .275" ID (Green)

3/8" OD X .275" ID (Gray)

3/8" OD X .275" ID (Blue)

1/4" OD X .170" ID (Orange)

4mm OD (5/32") (Green)

4mm OD (5/32") (Gray)

4mm OD (5/32") (Blue)

4mm (5/32") (Natural)

4mm (5/32") (Black)

TUBE SIZE / AIR PRESSURE REQUIREMENTS

90 psi±10 (621 ± 69 kPa)

80 psi ± 20 (at atomizer card)

(552 ± 138 kPa)

Variable

Variable

Variable

60-100 psi (414-689 kPa)

80 psi +/- 10 552 ± 70 kPa)

80 psi +/- 10 552 ± 70 kPa)

80-100 psi (552-873 kPa)

80 psi ± 10

(552 ± 70 kPa)

80 psi +/- 70 kPa)

Air Pressure

Requirements

Metric Tube Bundle

Fractional Tube Bundle

In electrostatic coating systems, the flow of high

voltage power from the power supply to the

atomizer is insulated from ground and isolated

from all other functions and equipment. When

the voltage reaches the atomizer, it is transferred

to the coating material where, by introducing a

negative charge, it causes the atomized fluid to

seek the nearest positive ground. In a properly

constructed and operated system, that ground

will be the target object.

The directed conduction of the electric charge

through its array of wires, cables, and equipment,

is accompanied by a variety of stray electrical

charges passing through the air by various means

such as: air ionization, charged particles in the

air and radiated energy. Such charges may be

attracted to any conductive material in the spray

area. If the conductive material does not provide

a safe drain to electrical ground, which will allow

the charge to dissipate as fast as it accumulates,

it may store the charge. When its electrical stor-

age limit is reached, or when it is breached by

external circumstances (such as the approach

of a grounded object or person, or one at lower

potential), it may discharge its stored charge to the

nearest ground. If there is no safe path to ground

(such as a ground wire or braided cable) it may

discharge through the air as a spark. A spark may

ignite the flammable atmosphere of a spray area.

The hazard area extends from the point of origin

up to as much as a twenty-foot radius. See the

NFPA Bulletin 33 for definition and limitations of

a hazard area.

It is a simple, but vital matter to be sure that all con-

ductive objects within the spray area are grounded.

All cabinets, housing, bases, supports and stands,

which are not by design, insulated from ground,

MUST be connected directly and INDIVIDUALLY

to earth ground.

Resting on a concrete floor or

being attached to a building column may not

always be sufficient ground. In order to provide

the best ground connection possible, always at-

tach a ground wire or insulated braided cable to

the terminal indicated by the ground symbol and

then to a proven ground. Always check ground

connections for integrity. Some items, such as

rotators and paint stands, may be supported on

an insulator, but all components of the system up

to the insulator MUST be grounded.

EQUIPMENT GROUNDING & SAFETY

RECOMMENDATIONS

Ransburg

LN-9263-08.5