Ransburg, Rma-303 dual purge/direct charge - maintenance, Turbine removal/replacement – Ransburg RMA Dual Purge Direct A12300 User Manual

Page 74

RMA-303 Dual Purge/Direct Charge - Maintenance

69

the cup wash port to provide additional leverage

to remove the inner shaping air ring.

Shaping Air Manifold Reassembly

(Lightly lubricate all o-rings prior to assembling.)

Carefully install the inner shaping air ring onto the

turbine threads. Tighten in a clockwise direction

until it seats against the turbine. Tighten set screw

to 5 lbs•in (0.564 Nm) torque to prevent shaping

air ring/manifold from rotating. Do not over-tight-

en! If replacing the solvent tube, install into the

atomizer body first and tighten with a 3/16" end-

wrench. Before installing the other end into the

inner shaping air ring, check the position of the

1/4-20 threaded hole. If it is less than 180° from

the fitting installed in the atomizer body, you must

install a loop (as shown in Figure 37) to prevent

tube from becoming pinched when outer shaping

air ring is installed. Do not kink the tube when

installing loop (granny knot) (see Figure 37).

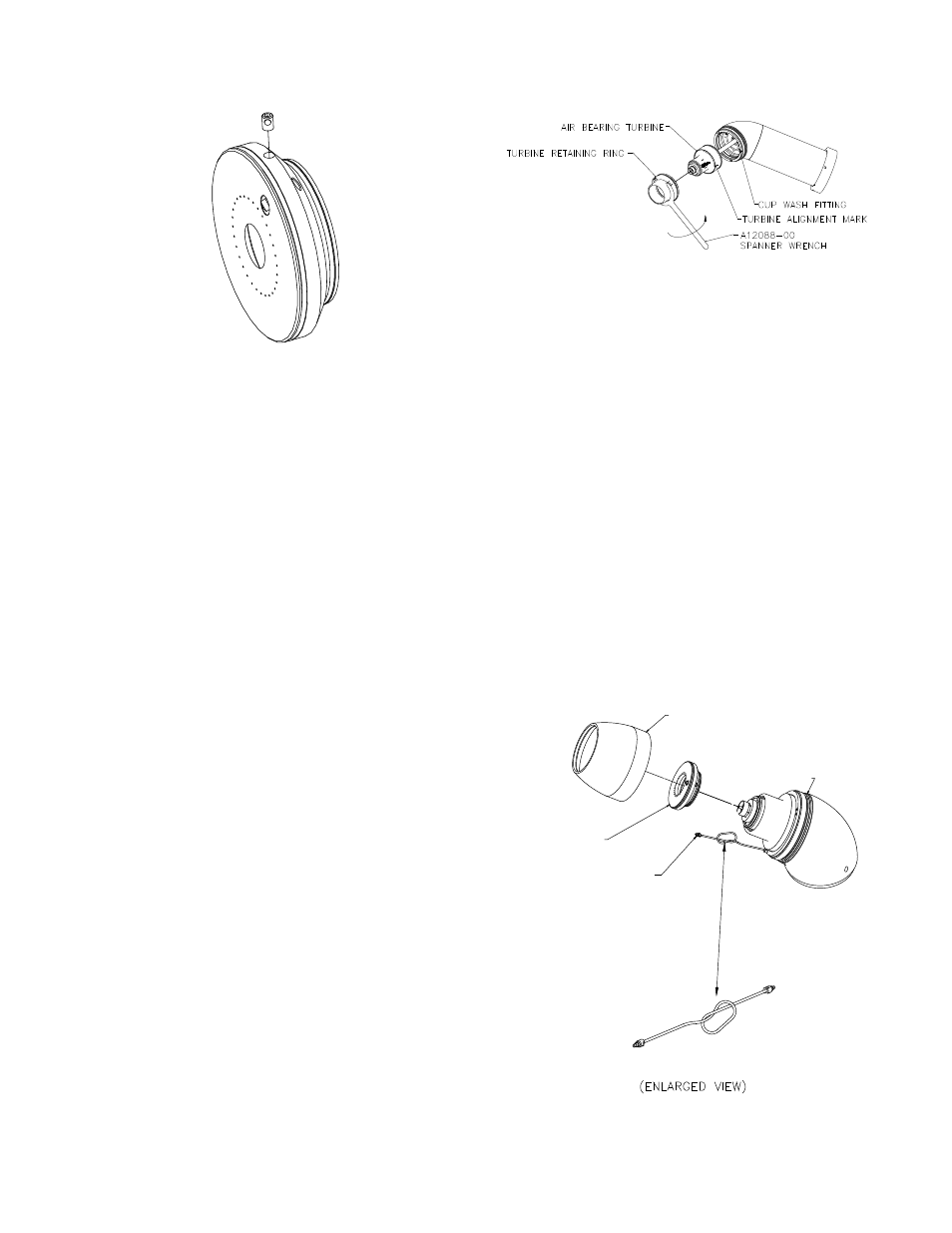

Turbine Removal/Replacement

Turbine Removal

Remove the turbine retaining ring by using the

spanner wrench A12088-00, turning the turbine

retaining ring in a counter-clockwise direction. Pull

the turbine out while rocking it from side to side.

Figure 35: Inner/Outer Shaping Air Manifold,

Solvent Tube Removal/Replacement

Figure 36: Turbine Removal

Turbine Replacement

Apply a light coating of o-ring lubricant to all the

o-rings and the threads of the turbine and turbine

retaining ring prior to assembly. Push the turbine

down into the cavity in the atomizer body. Align the

mark on the turbine with the mark on the atomizer

body. Install the turbine retaining ring and o-ring

by hand. Use the spanner wrench to tighten an

additional 1/8-1/4 turn. (Lightly lubricate o-ring with

petroleum jelly.) Check centering of fluid tube. If

fluid tube is centered, the turbine is fully seated.

If not, check tightness with spanner wrench. If

tube is not centered, again remove turbine and

check for causes, such as an o-ring fell off, fiber

optic not fully installed, foreign material on seating

surface, etc. Reinstall and recheck tube centering.

Figure 37: External Cup Wash Line

(Enlarged View)

Ransburg

LN-9263-08.5

COUNTER-CLOCKWISE

TO REMOVE TURBINE

RETAINING RING

OUTER SHAPING

AIR MANIFOLD

SHAPING AIR

MANIFOLD ASS'Y.

KNUCKLE O-RING

FERRULE AND FITTING

EXTERNAL CUP WASH LINE