Ransburg, Disassembly procedures, Rma-303 dual purge/direct charge - maintenance – Ransburg RMA Dual Purge Direct A12300 User Manual

Page 68: Atomizer removal/replacement, Rma-303 preventive maintenance schedule (cont.)

RMA-303 Dual Purge/Direct Charge - Maintenance

63

DISASSEMBLY

PROCEDURES

Atomizer Removal/Replacement

Using the applicator removal tool (76772-00),

insert the pin diameter of the wrench into one of

the four (4) holes of OD of the quick disconnect

ring. Apply a force to the tool in a counter-clock-

wise direction as shown in Figure 23. Completely

remove ring from robot mount plate and pull ap-

plicator straight out.

NOTE

For reassembly instructions, use the

reverse of the following disassembly pro-

cedures.

NOTE

To facillitate Atomizer removal from

hose manifold, a robot program should be

made that purges all paints and solvents

from the RMA-303. Ideally it would then

position the bell assembly in a bell remov-

al position where the bell cup is pointed

downward at a 30° angle. Any residual

solvents would be contained in the "J

bend" of the robot wrist.

NOTE

All o-rings described in the "Mainte-

nance" section of this manual should be

lubricated with a food grade petroleum jelly

or with a A11545 Petrolatum Jell Lubricant.

Ransburg

LN-9263-08.5

Procedure

MidShift

End of

Shift Weekly 2 Weeks

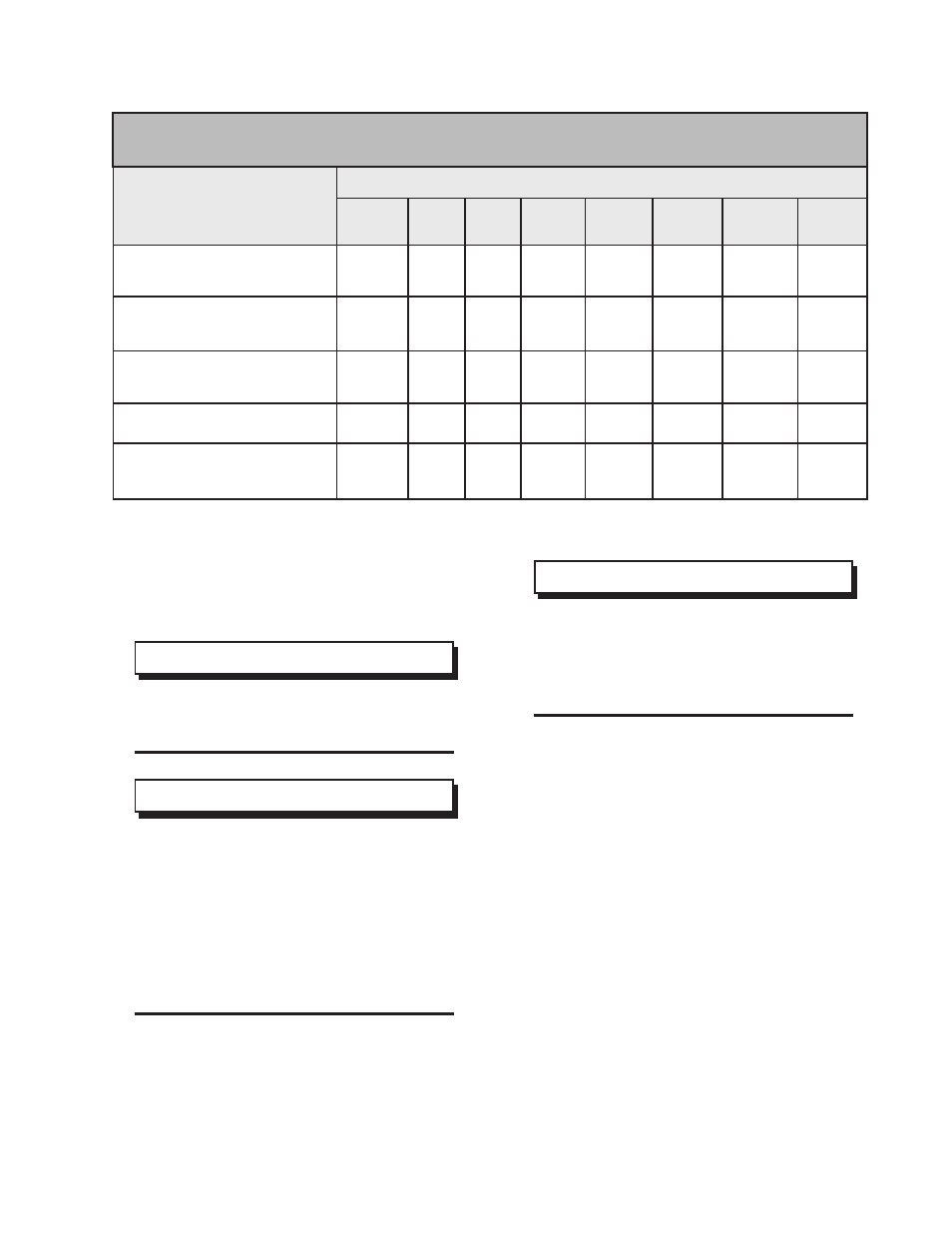

RMA-303 PREVENTIVE MAINTENANCE SCHEDULE (Cont.)

Inspect Turbine Spindle

taper and threads

X

Replace Bell Cups

X

X

X

Replace Splash Plates

X

X

Inspect and clean Spindle

Bore and Fluid Tube OD

X X

Inspect for fluid leaks

Daily

Check External Cup Flush

Carbine Tip for blockage

X X

Frequency

Monthly 3 Months 6 Months

Yearly