Ransburg, Gap between parts .01" max, Rma-303 dual purge/direct charge - maintenance – Ransburg RMA Dual Purge Direct A12300 User Manual

Page 75: Fluid tip removal/replacement

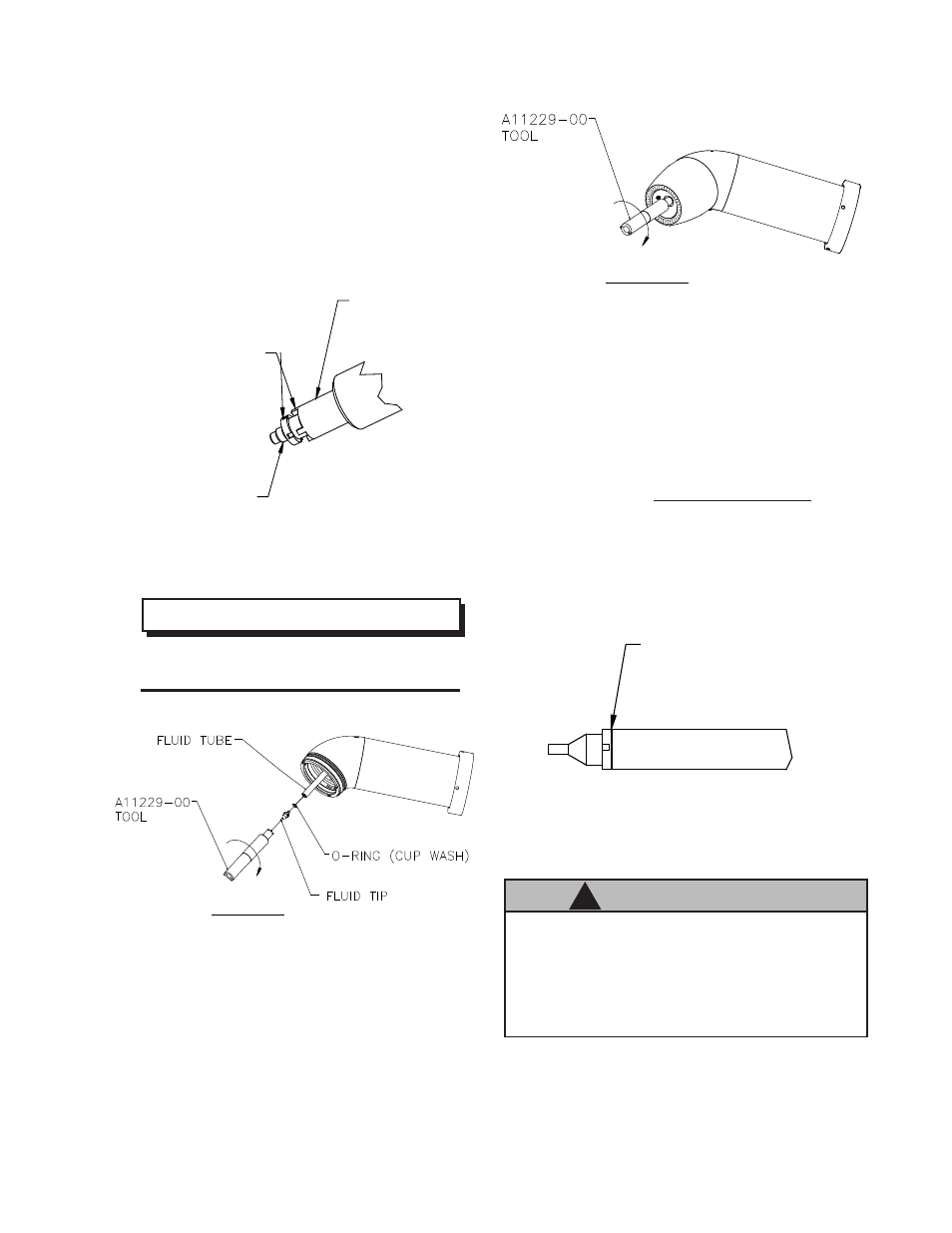

Fluid Tip Replacement

Ensure the tip openings are fully open and clean.

Apply an o-ring lubricant to the o-ring to help hold

it in place on the fluid tip. Insert the o-ring into the

undercut groove on the tip. Place the tip on the

tool and tighten in a

counter-clockwise direction

into the fluid tube.

Do not over-tighten. There

will be a small gap between the flange of the fluid

tip and the fluid tube (see Figure 40). Ensure

the o-ring is properly positioned when complete.

Tighten to 25-30 lbs•in (2.83-3.4 Nm) torque.

Figure 38: Fluid Tip Removal

To remove, turn the tip

CLOCKWISE.

The thread on the tip is

left hand.

NOTE

Figure 40: Fluid Tip Removal

RMA-303 Dual Purge/Direct Charge - Maintenance

70

Fluid Tip Removal/Replacement

Fluid Tip Removal

To remove the fluid tips, use the tip/tube removal

tool (A11229-00). Insert the tool over the tip and

engage the four (4) prongs of the tool into the four

(4) slots in the tips (see Figure 38).

Figure 39: Fluid Tip

The fluid tip may be removed either with the tur-

bine in place, or the turbine off the unit. Figure 40

shows removing the tip with the turbine in place.

This allows removal and replacement of the fluid

tip while the applicator is on-line.

Figure 41: Fluid Tip/Tube Gap

When removing fluid tip while turbine is

still installed.

Make sure to clean paint or fluid that may

leak and run onto the shaft or threads.

C A U T I O N

!

Ransburg

LN-9263-08.5

A11229-00

TOOL

FLUID

TIP

ENGAGE

PRONGS INTO

SLOTS

CLOCKWISE TO

REMOVE FLUID TIP

LEFT HAND THREAD

CLOCKWISE TO

REMOVE FLUID TIP

LEFT HAND THREAD

GAP

BETWEEN PARTS

.01" MAX.