Ransburg, Bell cup preventive maintenance – Ransburg RMA Dual Purge Direct A12300 User Manual

Page 63

RMA-303 Dual Purge/Direct Charge - Maintenance

58

Make sure that no solvent or other

contamination is allowed to enter the mo-

tor assembly (air bearing and outer shaft).

W A R N I N G

!

• Visually inspect for signs of fluid leaks around

fluid connections and manifold. Correct prob-

lem and clean paint from all components,

including internal portion of shroud.

• Reinstall bell cup and front shroud and re-

place cover on the outer housing (refer to

"Disassembly Procedures" in the "Mainte-

nance" section for definite instructions).

• Recheck bell cup tightness. Torque to 50-70

lbs•in (5.64-7.91 Nm).

BELL CUP PREVENTIVE

MAINTENANCE

It is the user's responsibility to ensure proper

maintenance of the atomizer bell at all times.

Bell cup failure due to inadequate cleaning or

handling will not be covered under Warranty. The

"WARNING" bullets listed are some examples of

improper handling which could adversely affect

performance or personnel safety and should not

be attempted for any reason.

Bell Cup Handling

Always verify that high voltage is turned off and

the atomizer bell has stopped spinning before

performing any type of handling maintenance.

Bell Cup Replacement

Bell cup wear is dependent on many factors such

as bell speed, flow rate, and type of coating being

applied.

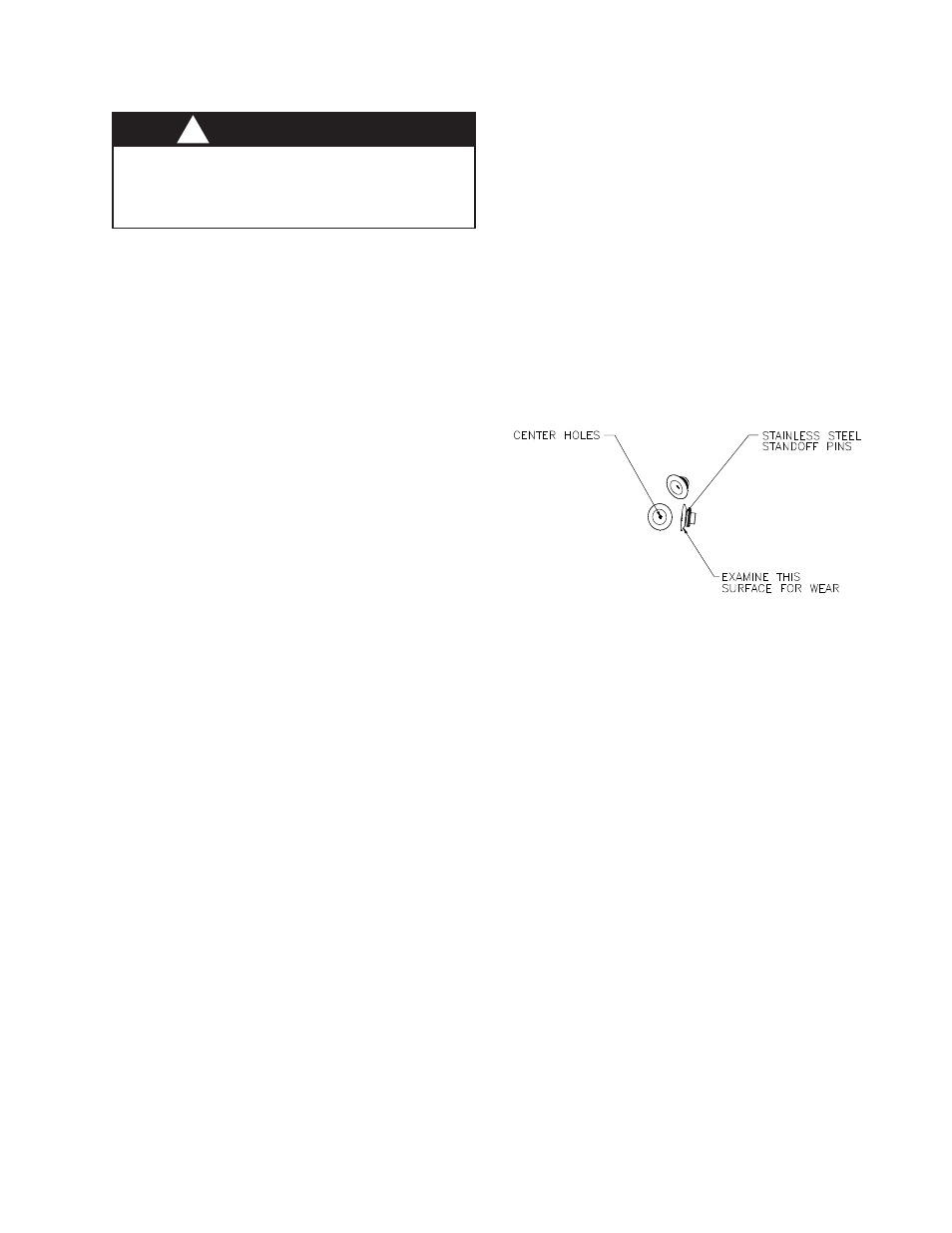

The bell cups shown in the following photos

indicates if a bell cup has some useable life or

should be replaced. Photo 1 shows a bell cup

that has some useable life. The grooves worn

around the splash plate pins are shallow. The

general appearance of the cup surface is smooth

and uninterupted. Photo 2 shows a bell cup that

needs to be replaced, as well as the splash plate

that was installed into the cup. The grooves are

deep, a visible groove exists at the outer edge

diameter of the splash plate, and there are no-

ticeable lateral grooves extending towards the

outer edge of the cup.

Figure 22: Inspection of Bell Cups

Ransburg

LN-9263-08.5