Ransburg, Rma-303 dual purge/direct charge - operation – Ransburg RMA Dual Purge Direct A12300 User Manual

Page 53

RMA-303 Dual Purge/Direct Charge - Operation

48

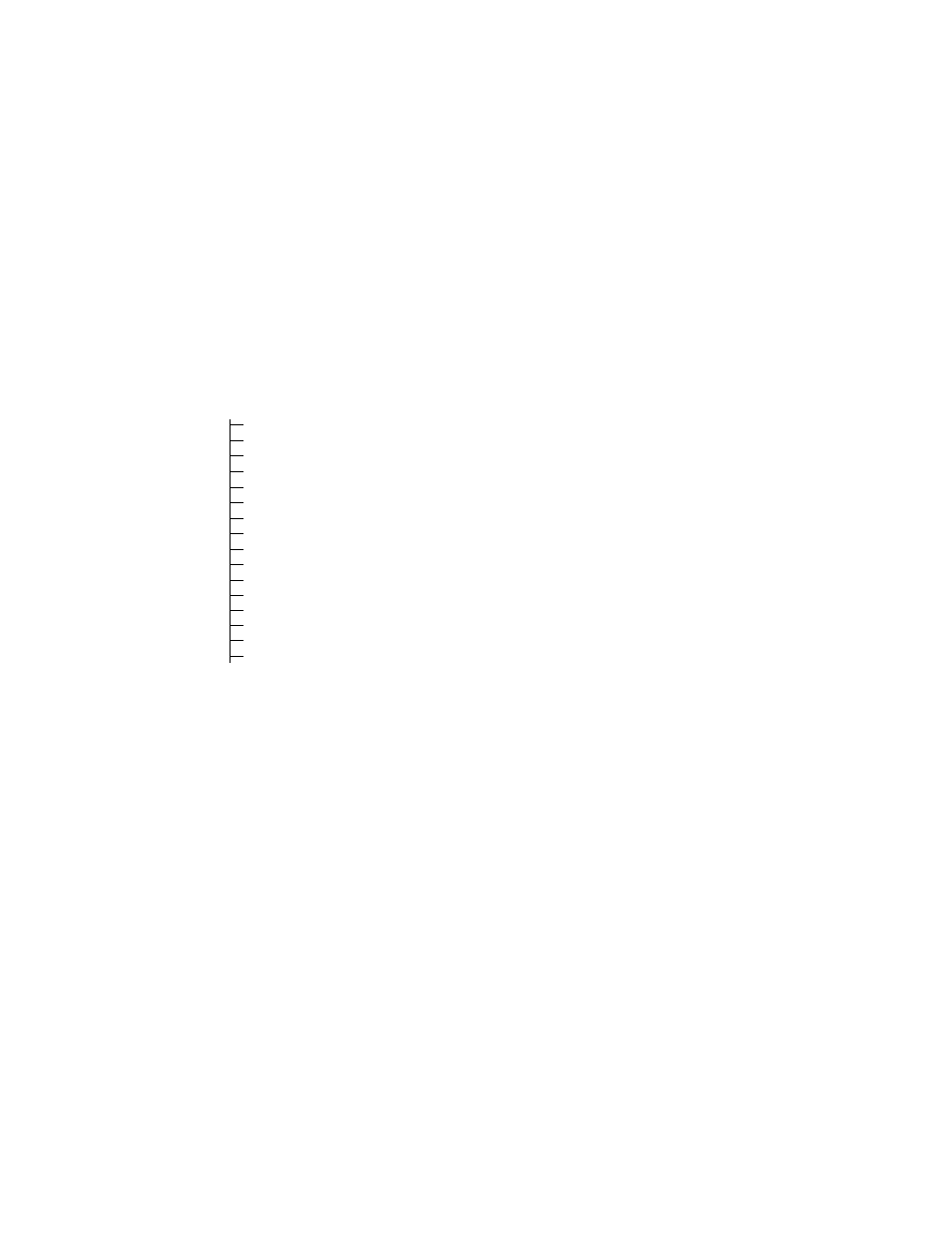

Figure 17: Typical Color Change Sequence

Ransburg

LN-9263-08.5

5.

Voltage Off/Setback Voltage - Immediately

preceeds the trigger off. Using a setback volt-

age shortens the cascade voltage ramp up-time.

Recommended setback voltage is between 30kV

and 50kV.

6.

Fluid Trigger Off - This should occur when the

target is typically 0-6-inches (0-152.4mm) past

the applicator centerline.

7.

Shaping Air to Setback - The setback flow

of air should never be below 70 slpm (2.6 SCFM).

PAINT TRIGGER ON SIDE #2 AND START SPRAYING

INTERNAL/EXTERNAL CUP WASH SEQUENCE- HV OFF

INTERNAL/EXTERNAL CUP WASH SEQUENCE- HV OFF

AIR IN TO CLEAR & DRY DUMP LINE

DUMP VALVE OPEN, LOAD PAINT TO VALVE BODY SIDE #2, DUMP VALVE OFF

PUSH PAINT THOUGH FLUOD COIL FROM SIDE #1, STOP SPRAYING

INTERNAL SOLVENT VALVE ON TO CLEAN COIL AND FLUID TUBE- HV OFF

DUMP TRIGGER ACTUATED SIDE #1

SOLVENT/ AIR CHOP FROM EXTERNAL SOURCE

AIR ON TO CLEAR & DRY DUMP LINE

DUMP VALVE OPEN, LOAD PAINT TO VALVE BODY SIDE #1, DUMP VALVE OFF

PUSH PAINT THROUGH FLUID COIL FROM SIDE #2, STOP SPRAYING

INTERNAL SOVENT VALVE ON TO CLEAN COIL, FLUID TUBE, BELL CUP- HV OFF

PAINT TRIGGER ON SIDE #1 AND START SPRAYING

DUMP VALVE ACTUATED SIDE #2

SOLVENT/AIR CHOP FROM EXTERNAL SOURCE

TY

PIC

AL

P

U

RG

E S

EQ

U

EN

CE

EV

EN

T

8.

Color Change Sequence - Used when

color is changed one to the other. Typical color

change sequence is shown in Figure 16.

(Note:

During this sequence, the applicator should

be moved to a position to collect the waste

material.) The sequence shown is a starting

point for processing, but the final sequence will

depend on the material being sprayed and the

solvent used to purge the applicator with.