Micromod Micro-DCI: 53IT5100A Indicator/Totalizer User Manual

Page 10

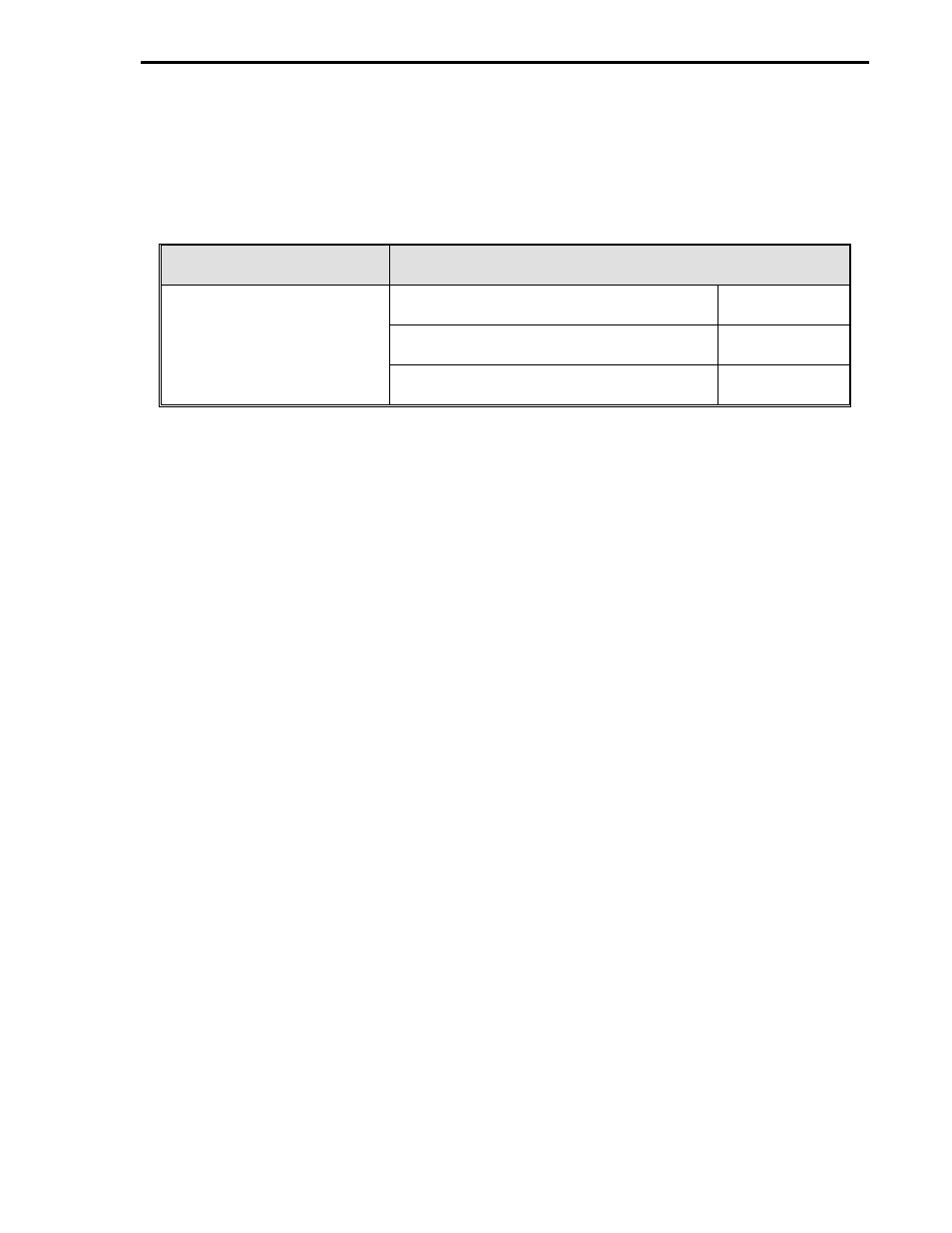

Directly beneath the horizontal keypad and concealed behind the front panel pull-down door is the

RS-232 Configuration Port. This port provides instrument access to the database for alternative

methods, other than using the front panel push buttons in engineering mode, to input selections

into the database for the operator displays. Alternative methods for loading or altering the instru-

ment database are summarized as follows:

Hand Held Configurer

(Procedure in Section 3)

Products on an IBM PC Compatible

Software/Hardware Package Reference

P/N 6988182U01 or

53HC3300 software package using

MC5FIG.EXE configuration program.

IB 53HC3300

P/N 6988182U02 with storage

cartridge capabilities.

53WS5000 software package using the

configuration program.

IB 53WS5000

Datalink SUPERVISOR-PC hardware and

software package.

IB 53SU5000

At the opposite end of the instrument case from the configuration port is the rear terminal board

which has two pin socket terminal strips (TB1 and TB2). As illustrated in Figure 1-2, the connec-

tors can be removed from the terminal strips to facilitate easier signal and power wiring when the

instrument is being installed. To ensure proper mating, only one side of the strips and connectors

is scalloped and the connectors are keyed. Also, as a further precaution, the signal connectors

that mate with the 22 pin terminal strip (TB1) are not the same size, as one has 12 screw lugs and

the other has 10 screw lugs.

Within the instrument case is the internal power supply. The internal power supply provides

power to the main board and output power for transmitters (24-26 V dc, 80 mA total available out-

put for instrument and transmitters).

Also within the instrument case is the main printed circuit board which has the necessary cir-

cuitry, firmware, and database for Indicator/Totalizer functionality. The main board has an embed-

ded microcontroller Application Specific Integrated Circuit (ASIC) that is surface mounted. The

PROM element and individual components are through-hole mounted.

A simplified input/output diagram of the Indicator/Totalizer is provided in the upper left corner of

Figure 1-2. As illustrated in the figure, the instrument can accept four Analog Inputs (ANI0-3 )

which are digitized as operands for firmware interpretation and execution (totalization). Each ANI

has a square root extractor and can accept linear or squared signals of 0-20 mA, 0-5 V, 4-20 mA,

or 1-5 V. Any one of the four analog inputs can be selected as the Analog Output (ANO0 ).

There are two contact inputs (CCI0 and CCI1 ) that have a closed recognition level of 1 V dc and

open recognition level of 4-24 V dc. Each CCI indicates an alarm state, for example, a CCI can

have a closed recognition level when a secondary pump is activated to support the primary pump

in maintaining a proper tank level.

The totalizers provide a running total of each ANI input. The totalizers are incremented in ascend-

ing order every 0.05 seconds, but all four totalizers are refreshed on the display every second.

Each ANI value can be independently adjusted by a scaling factor before being summed to the run-

ning total. The totalizer measured units, therefore, can differ from the process activity measured

units as determined by the scaling factor entries for each channel. Also available as selectable to-

talizer entries are rollover and dropout values. The rollover value specifies a maximum positive

value that causes the totalizer accumulator to reset to zero when the actual total reaches this

value. An output pulse is strobed to a 1 for one scan each time the actual total reaches the

Section 1. Introduction

1-5