Maintenance procedures, Maintenance procedures -93 – Luminex 100 IS Version 2.3 User Manual

Page 135

x

MAP Technology

Using Luminex 100 IS 2.3 Software

PN 89-00002-00-072 Rev. C

5 - 93

3. From the Restore Database From dialog box, select a database

backup file to restore and click Open. The system restores the

previously saved database. Notice that the files are organized by

date (month-day-year).

4. A Database Restored dialog box opens the next time you start

up the system. The dialog box prompts you to verify that the lot

information for CAL 1, CAL2, CON1, and CON2 reagents are

correct.

5. Click OK to verify that the lot information is accurate.

Maintenance Procedures

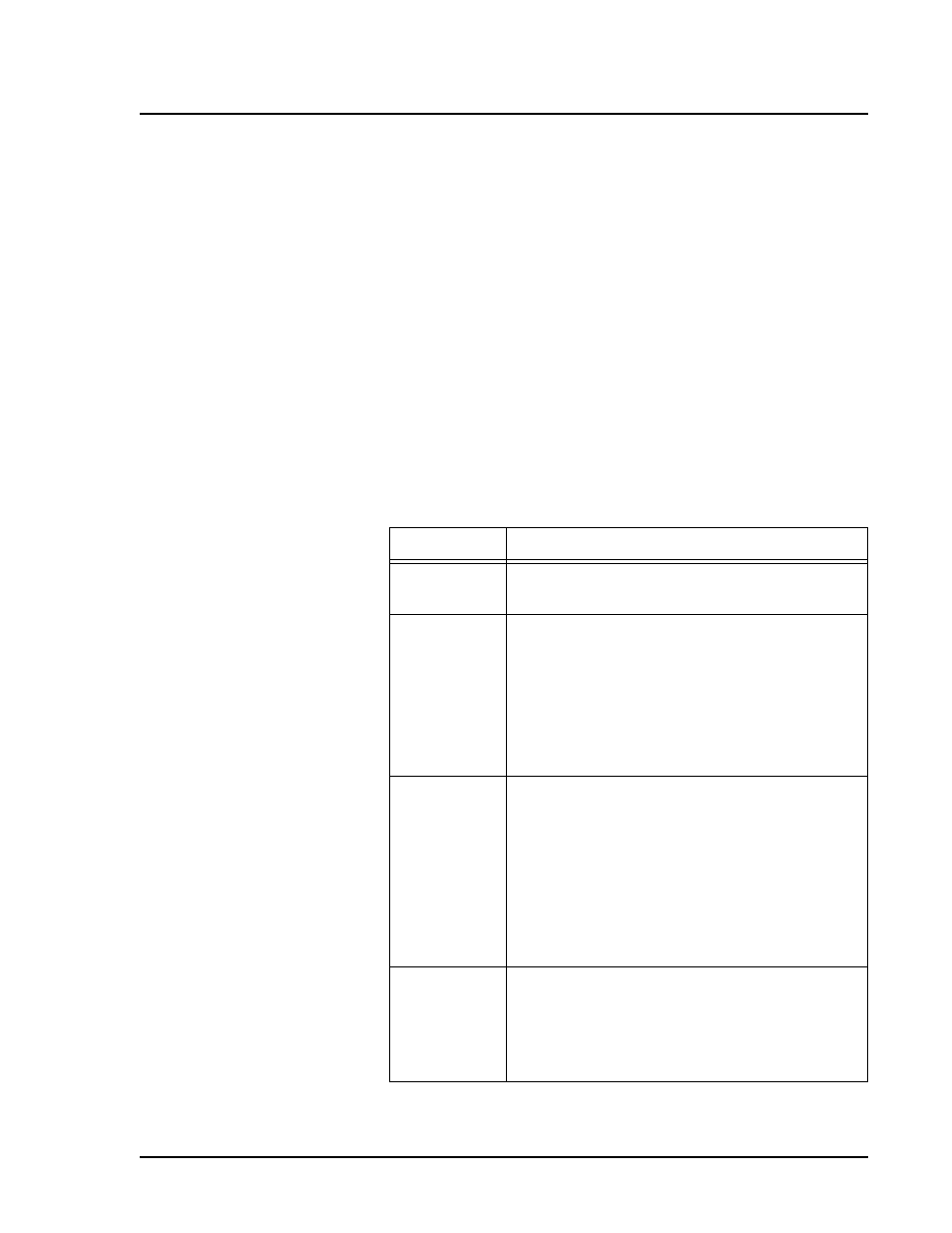

Table 5-11 shows a recommended schedule for maintenance

operations.

Table 5-11. Maintenance Operations:

Recommended Use Schedule

Operation

Recommended Use Schedule

Warmup

•

Daily

•

After four hours of system inactivity

Prime

•

Daily

•

To remove air from sheath fluid tubing

•

After performing these actions:

– refilling the sheath container

– removing and replacing sheath container

– changing the sheath fluid filter

– changing the syringe seal

Backflush

•

Troubleshooting and preventative

maintenance purposes only:

– to remove obstructions from the cuvette

– if fluid does not flow through the waste tub-

ing during prime cycles or during sample

acquisition

– if fluid drips from the sample probe during

priming and forms puddles of fluid on the

plate

Alcohol Flush

•

Daily

•

Before system calibration

•

After changing the sample probe

•

To remove air bubbles from the cuvette using

70% isopropanol or 70% ethanol