3 troubleshooting continued – Controlled Products Systems Group 1603-080 User Manual

Page 36

1603-065-T-4-13

34

•

Momentarily jumper terminal 6 to terminal 14. If input LED does not come ON, check terminal strip

or replace control board. If LED does come on, go to the next step.

•

Momentarily jumper terminal 2 to terminal 3 (Caution – High Voltage). The motor should run.

•

Momentarily jumper terminal 2 to terminal 4 (Caution – High Voltage). The motor should run in

opposite direction of above.

•

If motor does not run in either or both steps above, bad motor, motor capacitor or wiring to motor.

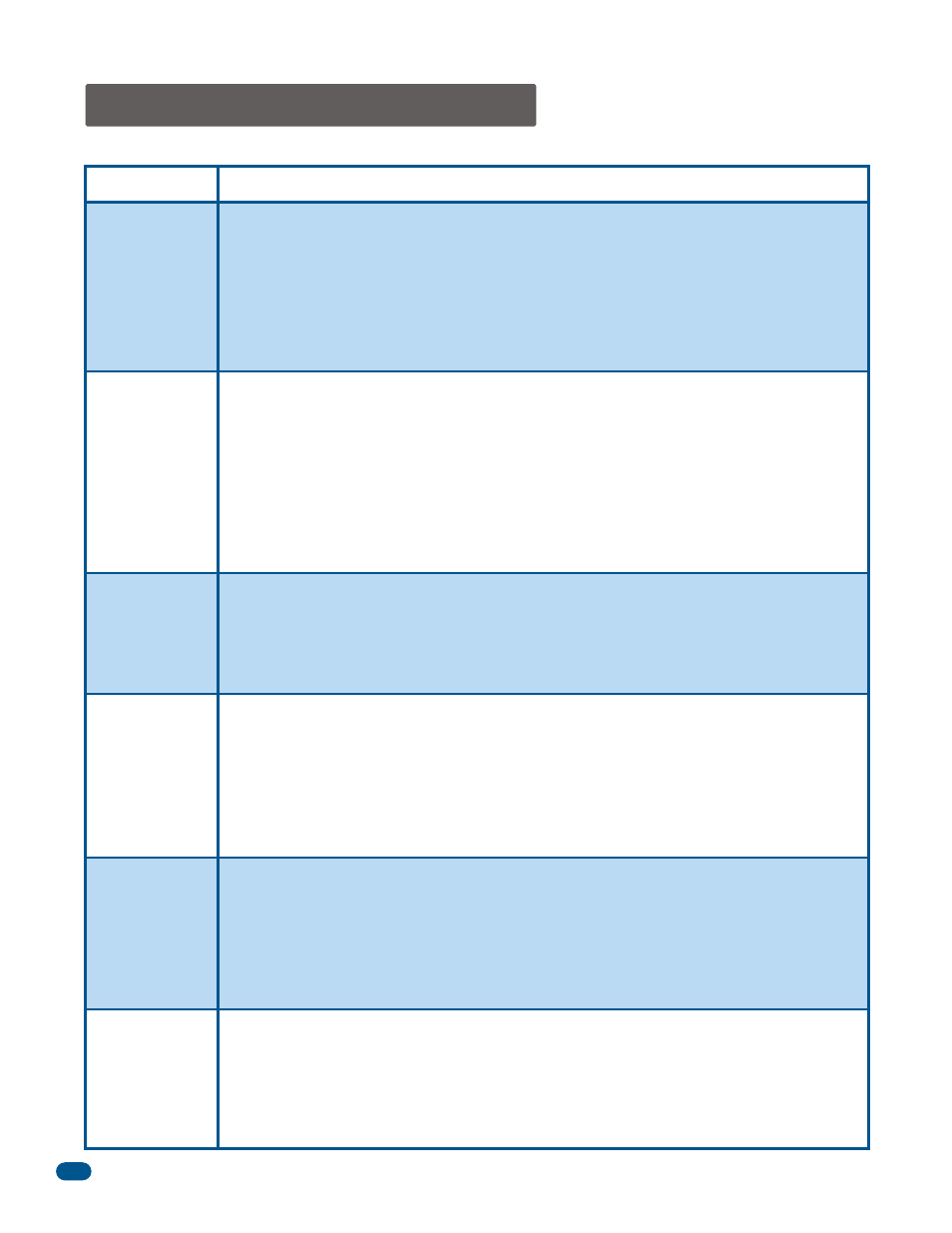

Operator will not

run. Power LED

is ON.

•

Check to be sure SW1, switch 4 is in the ON position.

•

Down input must be activated, and then deactivated to cause arm to rotate down.

Down input / down

loop will not rotate

arm to down

position.

Loop detector LED

is on continuously.

Symptom Possible

Solution(s)

Loop detector LED

never activates.

Battery back-up

system will not

raise arm upon

power outage.

•

Increase loop detector sensitivity.

•

Check continuity of loop wire. Should be 0 ohms. If continuity check indicates anything other than

0 ohms, check all connections. Replace loop wire.

•

Move loop detector board to the other loop detector port on the control board, and then check loop

operation. If loop detector still fails, replace loop board.

•

If loop detector operates OK in the other loop port, replace control board.

•

Check that the back-up system toggle switch is in the ON position.

•

Check to be sure that the 2340-010 battery back-up control board switch settings are set as

described in SECTION 7.

•

Check the batteries for proper voltage, replace if necessary.

•

Replace the 2340-010 Back-up control board.

•

Activate the reset switch on the loop detector.

•

Decrease loop detector sensitivity.

•

Check loop wire for resistance to ground with meg-ohm meter. Should be 100 meg-ohms or higher.

If less than 50 meg-ohms, replace loop wire.

•

Be sure loop lead-in wire is twisted at least 6 turns per foot.

•

Be sure all loop connections are soldered.

•

Replace loop detector.

•

Check LEDs on terminals 6, 7 and 9. Any of these ON will hold the arm in the UP position. This

indicates a shorted input.

•

Check the LEDs on the loop detectors. Any ON will hold the arm in the UP position. Possible loop or

loop detector problem.

•

If auto timer is not used (SW1, switch 7 off ), check to be sure SW1, switch 6 is in the ON position.

This will cause terminal 6 to rotate the arm down when it is activated.

•

Check to be sure SW1, switch 4 is ON. This will cause terminal 8 activation, then deactivation to

rotate arm down.

Arm rotates up,

but will not

rotate down.

9.3 Troubleshooting Continued