Controlled Products Systems Group 1603-080 User Manual

Page 34

1603-065-T-4-13

32

9.1 Maintenance

SECTION 9 - MAINTENANCE AND TROUBLESHOOTING

When servicing the gate operator, always check any secondary (external) reversing devices (loops, photo eyes, etc.) for proper

operation. If external reversing devices cannot be made operable, do not place this operator in service until the malfunction can

be identified and corrected.

Always check the inherent reversing system when performing any maintenance. If the inherent reversing system cannot be

made operable, remove this operator from service until the cause of the malfunction is identified and corrected. Keeping

this operator in service when the inherent reversing system is malfunctioning creates a hazard for persons which can result

in serious injury or death should they become entrapped.

When servicing this gate operator, always turn power OFF!! If equipped with batteries, make sure battery power switch is OFF.

If gearbox requires oil, use only Mobil SHC-629 Synthetic Gear Oil. Do not completely fill gearbox with oil. Gearbox is full

when oil completely covers inspection window.

Inspection and service of this gate operator by a qualified technician should be performed anytime a malfunction is observed or

suspected. High cycle usage may require more frequent service checks.

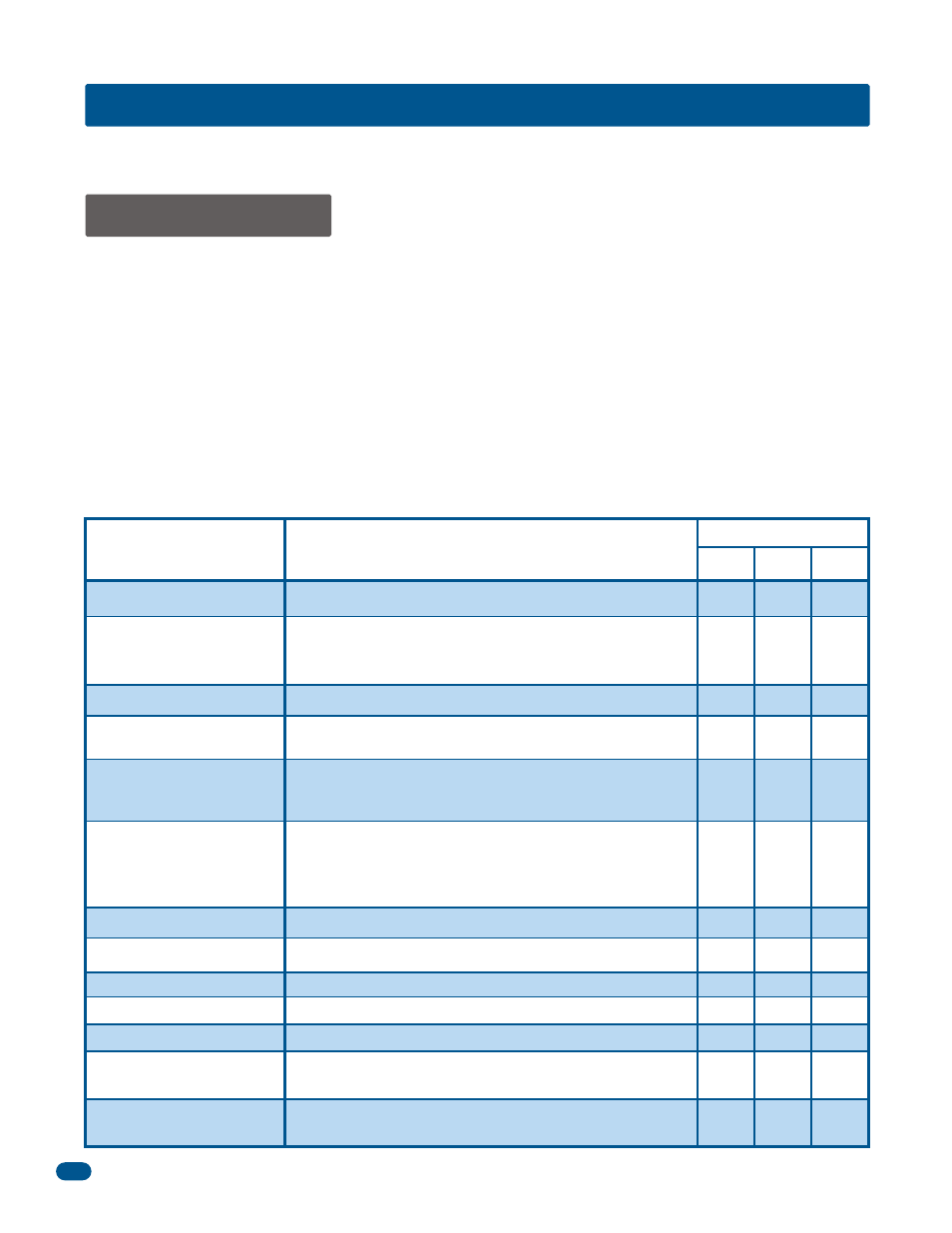

Operator

Component

Maintenance

Monthly Interval

6

3 12

Arm

(

s

)

Auto Spike System

Batteries

(On select models)

Convenience Open System

(Not on all models)

Drive Belt

(

s

)

✓ ✓

✓

✓ ✓

✓

✓

✓

✓ ✓

✓

✓ ✓ ✓

✓ ✓

✓

✓ ✓

✓ ✓

✓ ✓

Fire Dept.

Gearbox

Linkages

Loop(s)

Pulleys

ERD Reversing System

Secondary Reverse

Device(s)

Complete System

If operator is equipped with optional convenience open system,

check the batteries for any leakage or loose connections.

Batteries should be replaced every two years.

Check for alignment, tightness and wear.

Check for alignment, tightness and wear.

Check for shaft alignment, tightness of hardware and wear of

spikes. Make sure all tunnel plates and ramps are securely

fastened to concrete.

Check all external ground loops for proper operation.

Check set screw for tightness.

Perform a complete system check. Include all reversing devices,

loops, access system devices, Fire Dept. access devices, etc.

Check emergency vehicle access device for proper operation.

If operator is equipped with optional DC open system, check to

be sure the system opens the arm upon loss of AC power.

Operator should resume normal operation when AC power has

been restored.

Check internal linkages for wear. Inspect bushing for wear.

Check oil level and fill if necessary. Do not overfill.

Check that the arm reverses on contact with an object in closing

cycle. Adjust the reversing sensor if necessary.

Check electric reversing edges and photo-cells for proper

operation.