Fluid Components International GF90_GF92 User Manual

Page 61

Doc. No. 06EN003229 Rev. H

57

GF Series Flow Meter Models GF90/GF92

FLUID COMPONENTS INTERNATIONAL LLC

http://www.fluidcomponents.com

11. Repeat steps 8 through 10 for 75 psig, 50 psig and 25 psig. The recorded values for flow temperature

and pressure are the instruments in-situ baseline calibration readings. All future verification readings

will be compared to these baseline values and should be within 2 % of these indicated readings.

12. The initial baseline calibration readings can be compared to the factory Verical calibration readings. If

the local atmospheric pressure is within 0.50 psi of atmospheric pressure during the factory Verical

calibration (located on the factory calibration sheet). The readings should be within 5 %.

13. Return the instrument electronics to the normal operation mode by pressing the “Home” key twice and

then pressing the no. “1” key. Place probe assembly back into the correct location in the center of the

process piping as indicated in the installation section of the operation manual. Return to normal

operation group if VeriCal group differs from normal operation group.

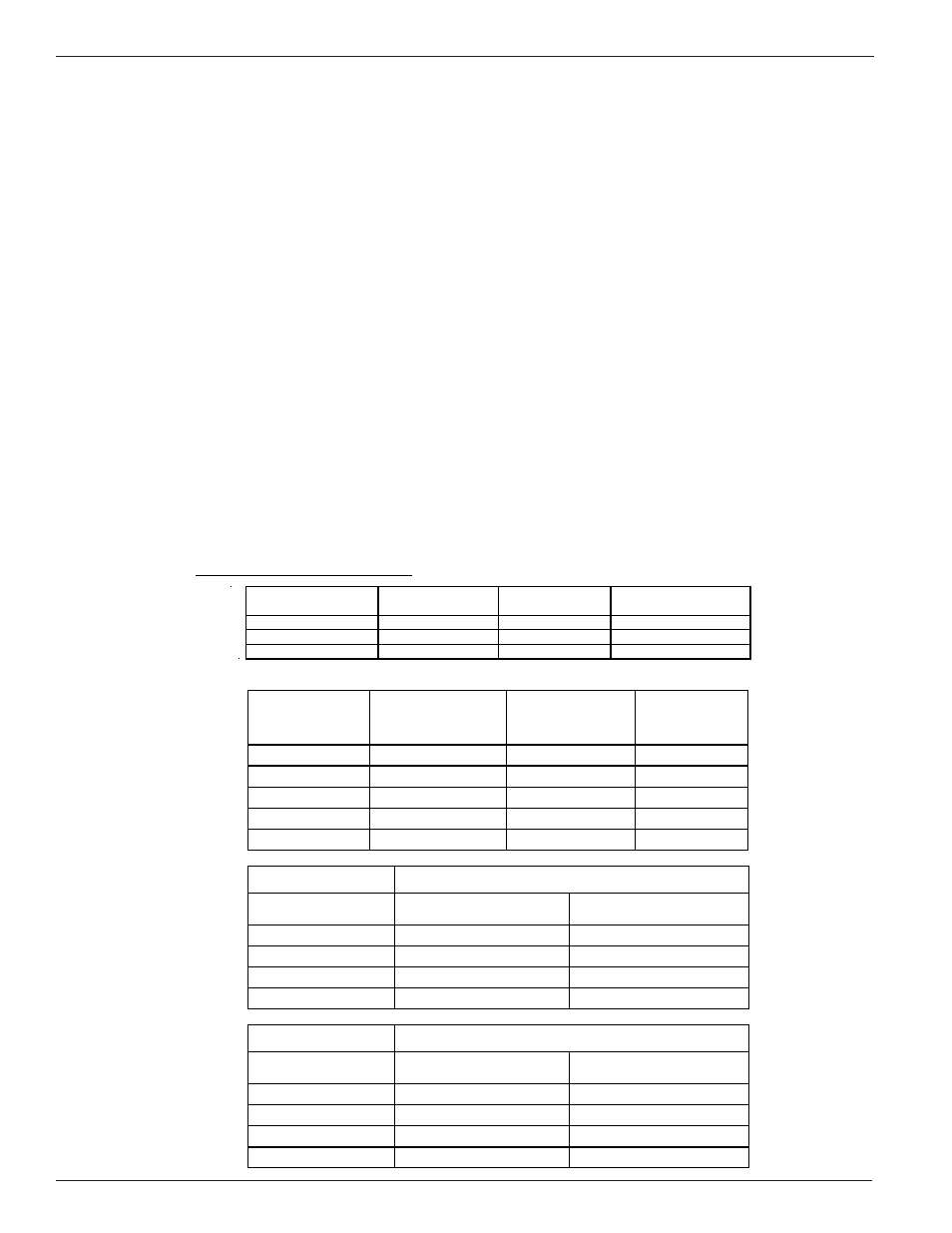

Calibration Verification (example)

C u s to m e r

O rd e r:

C 0 2 4 0 5 7

E q u ip . N o .:

C a l. D u e D a te

C u s to m e r:

E L -0 2 9

9 -1 2 -0 9

D a te : 0 2 -1 9 -0 9

E L -3 8 3

7 -2 8 -0 9

S e ria l N o .:

2 4 4 1 1 0

V eriC al

In dicated

Pressu re,

psig

P ressure

T ran sdu cer m A

O utp ut

In dicated F lo w

(SF PS )

In dicated

T em perature

D eg. F

100

29.96 72.4

75.00

34.25 74.2

50.00

22.15 74.7

25.00

10.55 75.3

0.000

0.000 78.3

Field B aseline

D ate:

In dicated

Pressu re, p sig

In dicated F lo w

(SF PS )

In dicated T em p .

Field C heck 1

D ate:

In dicated

Pressu re, p sig

In dicated F lo w

(SF PS )

In dicated T em p .

Recommended Procedure with Pressure Transducer

The pressure transducer is located in the VeriCal Regulator Assembly box. The transducer is wired to the

electronics assembly as shown in page 58.

The pressure transducer option provides a flow, temperature and pressure indication on the GF electronics

display. These parameters are accessed through the 7.4 menu.

The verification procedure is the same as the steps outline in the previous section (without pressure

transducer) steps 1 - 13. The only difference is that flow, temperature and pressure reading are all available

on the GF electronics display. The analog gauge mounted in the Regulator Assembly box can be used as a

caparison to the pressure transducer output as indicated on the GF electronics display.

FCI Certificate

For Customer Input Records