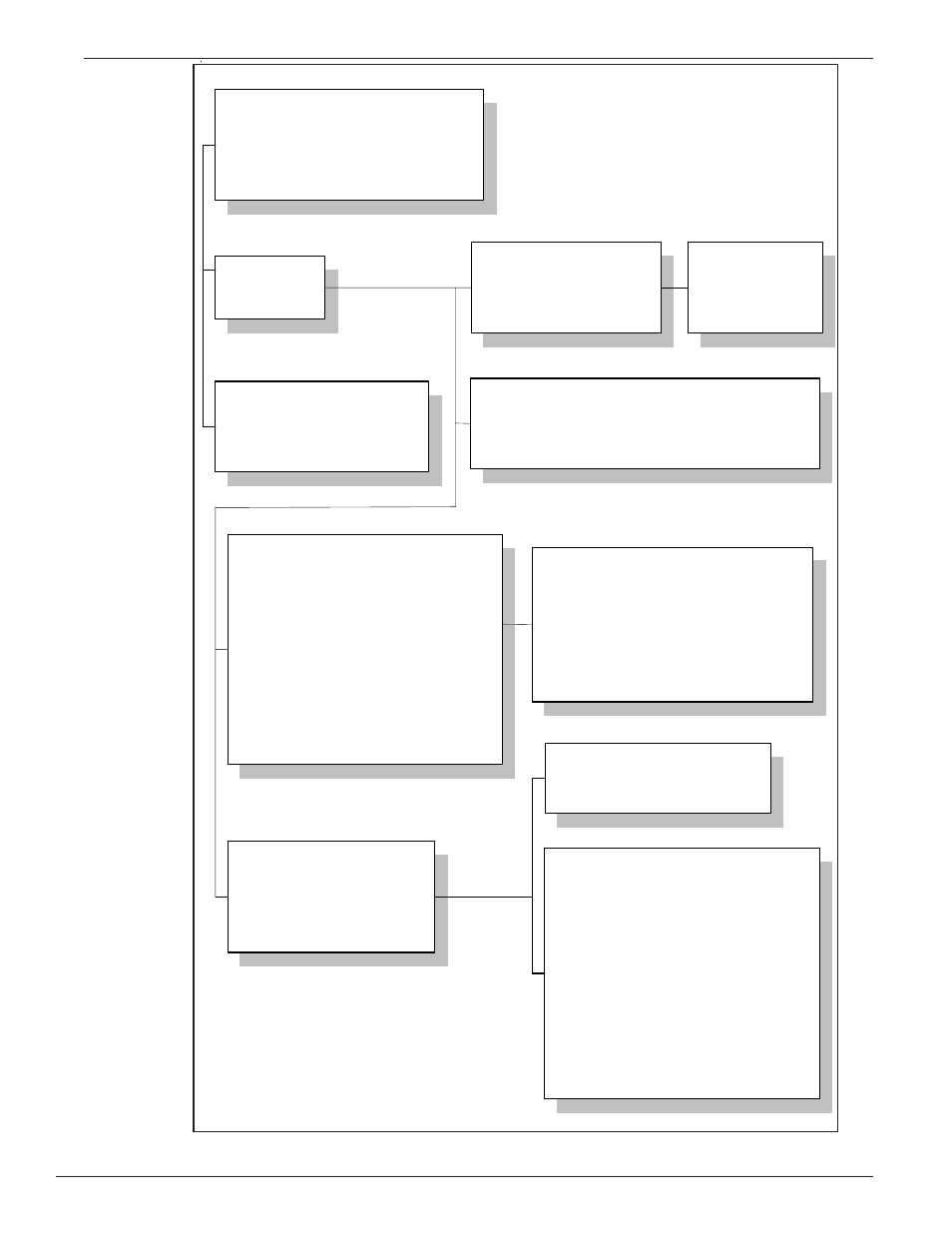

Gf90/gf92 hart menu tree – Fluid Components International GF90_GF92 User Manual

Page 27

Doc. No. 06EN003229 Rev. H

23

GF Series Flowmeter Models GF90/GF92

FLUID COMPONENTS INTERNATIONAL LLC

http://www.fluidcomponents.com

1 DEVICE SETUP

2 VOLT (Displays actual process value, i.e. flow)

3 LRV (Displays configured lower range value)

4 URV (Displays configured upper range value)

5 I OUT (Displays actual output current in mA)

6 % RANGE (Shows output current in % output span)

7 DATALOGGER

1 MAX. VALUE (Displays highest process

value since reset)

2 MIN. VALUE (Displays lowest process

value since reset)

3 RESET MIN/MAX (Reset the memory

holding min/max data)

1 LOOP TEST (Enter/Change loop

current to fixed value)

2 D/A TRIM (Connect a reference meter

(5 digit). Compensate for

the inaccuracy in output

D/A converter)

3 SENSOR TRIM

1 SIGNAL CONDITION

2 SENSOR TYPE (Enter Sensor type

i.e. RTD, T/C, mV, Ohm, Pot)

3 LRV (Enter lower range value)

4 URV (Enter upper range value)

5 DAMP (Enter damping value)

1 4 mA FIXED OUTPUT

2 20 mA FIXED OUTPUT

3 OTHER (Inter value of fixed current output)

4 END (Leave the menu)

1 SENSOR (mV Hi)

2 USL (Upper sense level

i.e. 1000 mV)

3 LSL (Lower sense level

i.e. 0 mV)

4 MIN SPAN (20 mV)

1 FACTORY TRIM (Offset and gain values are

reset to factory settings)

2 ONE POINT TRIM (Enter reference temp. value for a

non-calibrated sensor. Displays measured

temperature. If ref temperatures are different,

enter this value.

3 TWO POINT TRIM (Enter 2 reference temperature

values. Displays actual measured temp. If

reference temps are different, enter the

values. The gain is #1, the function curve will

change the slope and not start in the zero

point)

4 VOLT. (Not used by FCI)

5 S. OFF. (This is the difference between the measured

and the reference value. Enter this value)

6 S. GAIN (Enter this value. This adjustment

corresponds to the 2-point trim. However

the function curve will start in the zero point.

MAIN MENU

1 DEVICE SETUP MENU

7 DATALOGGER MENU

3 DEVICE INFO

2.1

4.1

1 DISTRIBUTOR (Displays name Kamstrup)

2 MODEL (Displays name FlexTop HRT)

3 DEV ID (Displays device serial number)

4 TAG (Enter tag number (identify FlexTop HRT))

5 DATE (Enter date of choice, i.e. date of event)

6 WRITE PROT. (Displays write protect status, NONE)

7 DESCRIPTOR (Enter description, ie a location code)

8 MESSAGE (Enter message, i.e. a warning)

9 FINAL ASMBLY NUM (Enter 8 digits, i.e. ref #

identifying sensor and transmitter during a

calibration session)

10 REVISION #'s (Displays the rev #'s of command set

(5), the FlexTop HRT(2) and the DD software (3))

11 HART OUTPUT

1 POLL ADR (Enter the polling adr. for the FlexTop

HRT. Observe that poll adr = 0

automatically sets the FlexTop HRT in

analog mode, resulting in a mixed-signal

setup. If intent is to connect several

FlexTop's in Multi-drop mode, poll

addresses 1 to 15 must be used.

2 NUM PREAMS (Displays number of preamble

characters sent by master to ensure

sync with the slave device.

GF90/GF92 HART

MENU TREE

1 INPUT SETUP

2 OUTPUT SETUP

3 DEVICE INFO.

4 DIAG/SERVICE

1 INPUT SETUP

1 Signal Condition

1 UNDER LIM (Enter the output current for measurements LOWER

than configured range, i.e. if temp. falls below 0°C)

2 OVER LIM (Enter the output current for measurements HIGHER

than configured range, i.e. if temp. goes above 100°C)

3 SENS ERR (Enter the output current in case sensor fails.

2 OUTPUT SETUP*

11 HART Output

*This is a sub menu, where the out-of-range and

sensor-burn-out can be entered.

4 DIAG/SERVICE**

1 Loop Test

3 Sensor Trim

**WARNING:

To enter this menu, remove the loop from automatic

control. All trim adjustments can be carried out from

the configurator only - not from the FlexProgrammer.

Figure 12. HART Module Menu Tree