Fluid Components International GF90_GF92 User Manual

Page 21

Doc. No. 06EN003229 Rev. H

17

GF Series Flowmeter Models GF90/GF92

FLUID COMPONENTS INTERNATIONAL LLC

http://www.fluidcomponents.com

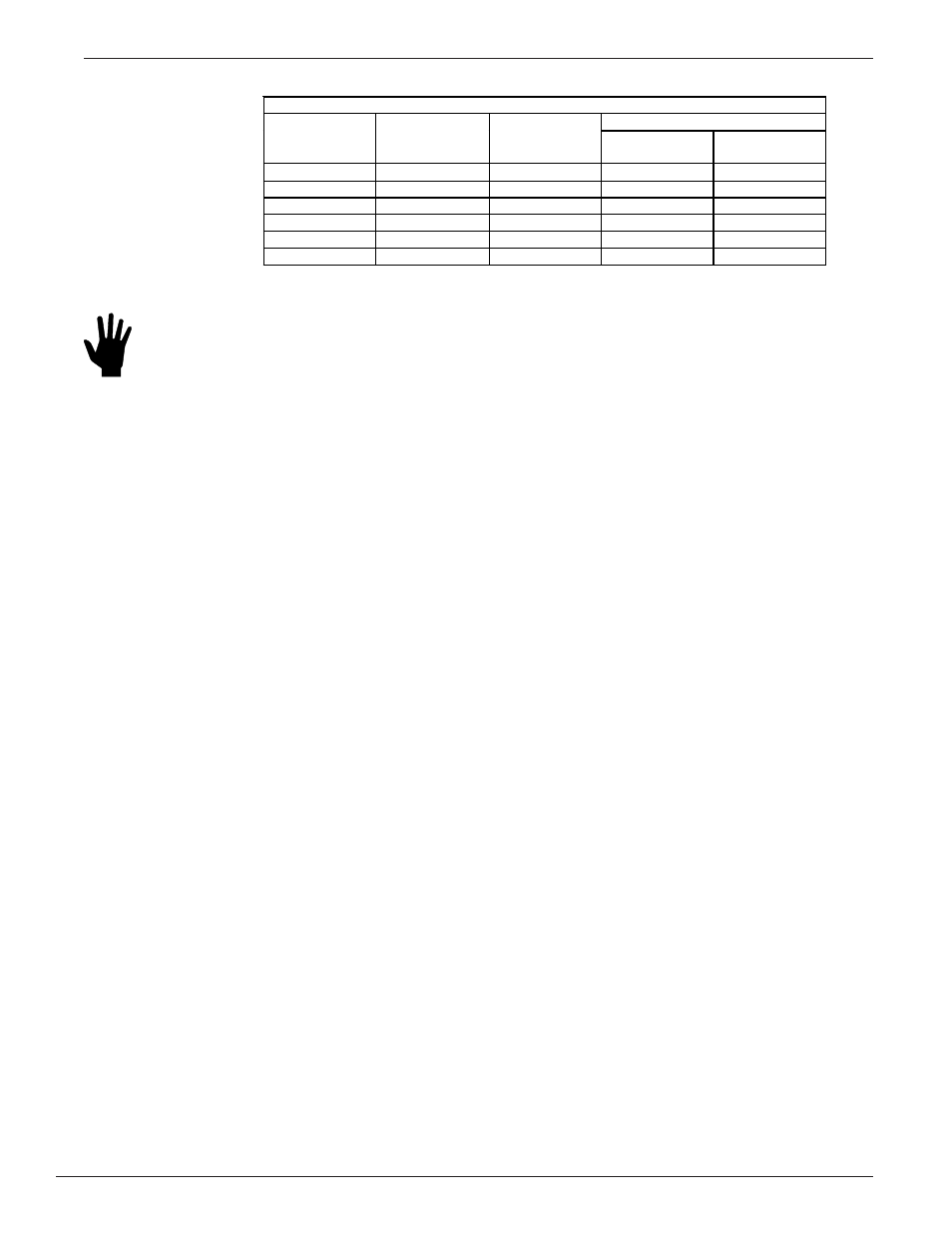

W IRE GAGE CONVERSION TABLE

Minim um

O.D.

of

W ire

Gage Stranding

Strands/Gage

Nominal O.D.

of Strand (in)

Inches mm

24 10/34

0.0063

0.024

0.584

22

7/30 0.010 0.030 0.762

20 10/30 0.010 0.037 0.890

18 16/30

0.100

0.047 1.20

16 19/29

0.113

0.058 1.47

14 19/27

0.0142

0.071 1.85

Table 2. Wire Conversion

Input Power

CAUTION:

If 24 VDC is used as a power source, the terminals are not power isolated.

The flow transmitter is powered by 115 VAC, 230 VAC or 24 VDC (only one power source is needed).

If 115 VAC is used, wire it directly to JP1 and position switch S1 to be in the 115 V position. See

Figure 8 for details. If 230 VAC is used, position switch S1 to be in the 230 V position and then wire

the power directly to JP1. See Figure 8 for details. If 24 VDC is used, it is wired directly to JP1 as

shown in Figure 8.

The installation of an AC line disconnect switch (and possibly a fuse) between the power source and

the flowmeter is strongly recommended. This facilitates easy power disconnection during calibration

and maintenance procedures as well as an added safety feature.

Remote Transmitter

Feed the flow element cable and the two voltage/current output cables through the left access port in the

remote enclosure. Similarly, feed the AC power line and the two relay cables through the right port.

This separates the I/O signal and low voltage DC lines from the high voltage AC and relay lines. See

wiring diagram, Figure 8 for the flow element wiring to JP3. Customer connections needing to be made

are to JP4 and JP5 (relay logic), and also to JP6 (current or voltage).