FlexLink Spiral Elevator User Manual

Page 67

Technical maintenance

Create

d

by EBCCW

0

0

:06

Page 61 of 68

5478EN-3

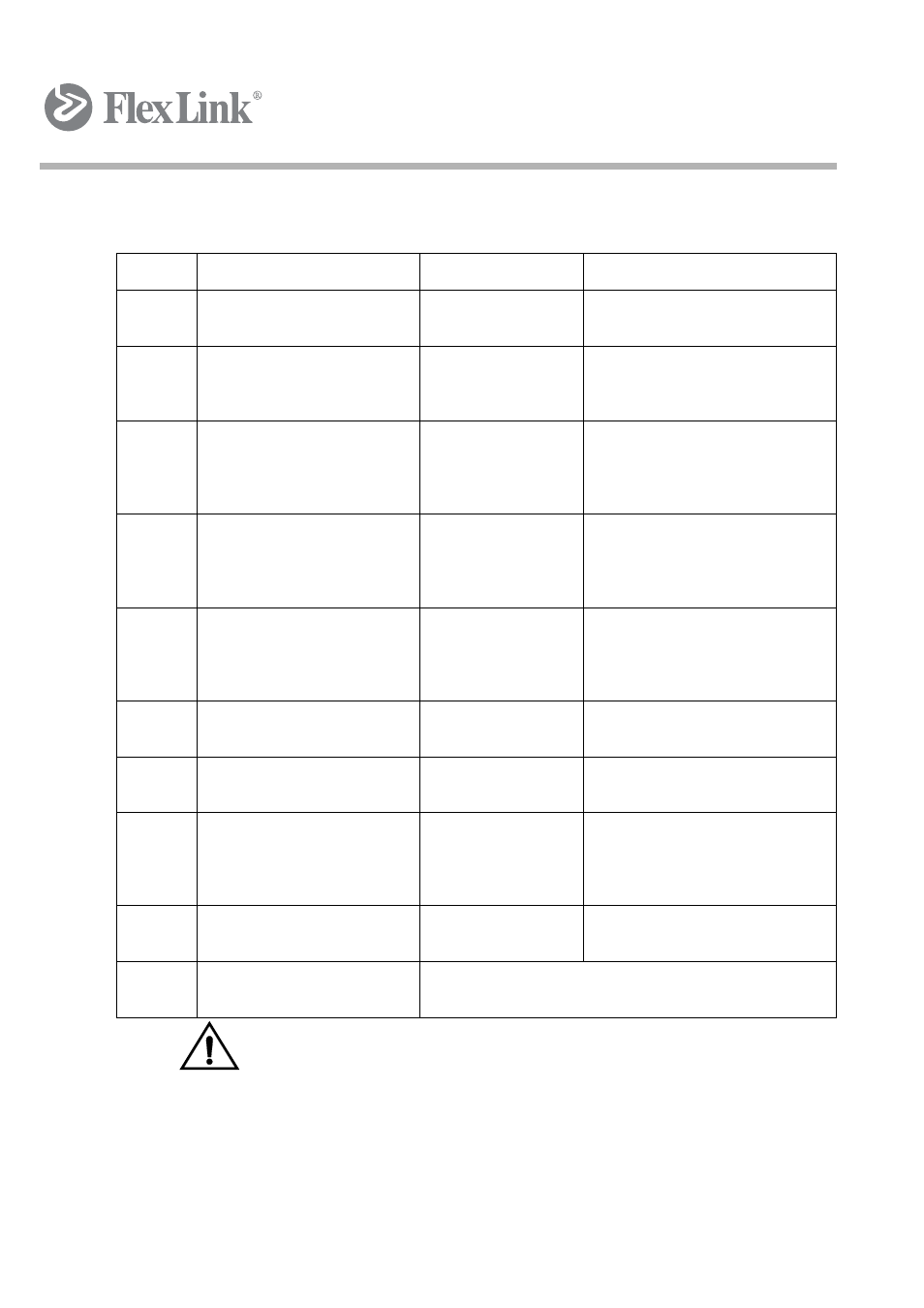

Maintenance schedule Spiral Elevator

.

Note! Make sure that the main switch has been switched off, and

safely isolated.

No. Execution

Interval

Remark

1.

Clean conveyor

Monthly

Regular cleaning depends on

product and environment

2.

Check the conveyor chain for

broken or missing conveyor

plates, replace if necessary

Daily

It is the task of the operator to

check this daily (see user’s

manual)

3.

Check the chain tension

Monthly

Remove a link if the chain is 38.5

mm too long. If more than two

links at the same time are to be

removed, contact the supplier.

4.

Check the sprocket wheel

and alignment. Replace or

align if necessary

Monthly

Faulty alignment of the sprocket

may cause permanent wear or

make the chain derail and can so

cause serious stoppages.

5.

Check the guide rails for

dents, damages and

connection

Monthly

Replace guide pieces if they

damage the products to be

transported. If the cause is bad

guide rail, contact the supplier.

6.

Clean inside below ends

Monthly

Accessible dirt will accumulate at

the bottom side.

7.

Check the drive for oil

leakage and undue noise

Monthly

Repair or replace if necessary.

See the troubleshooting list

8.

Check whether the Motor is

fastened well to the Spiral

Elevator. Tighten the bolts if

necessary

Monthly

Drive vibrations can make the

bolts loosen, then faulty alignment

of the drive can bend the shaft

and the chain may derail.

9.

Check the oil level in the

Motor, fill up if necessary

Monthly

Take a look at the gear motor

specifications of the manufacturer

10.

Change the oil in the Gear

motor

In accordance with the gear motor specifications of the

manufacturer