FlexLink Spiral Elevator User Manual

Page 64

Technical maintenance

Page 58 of 68

5478EN-3

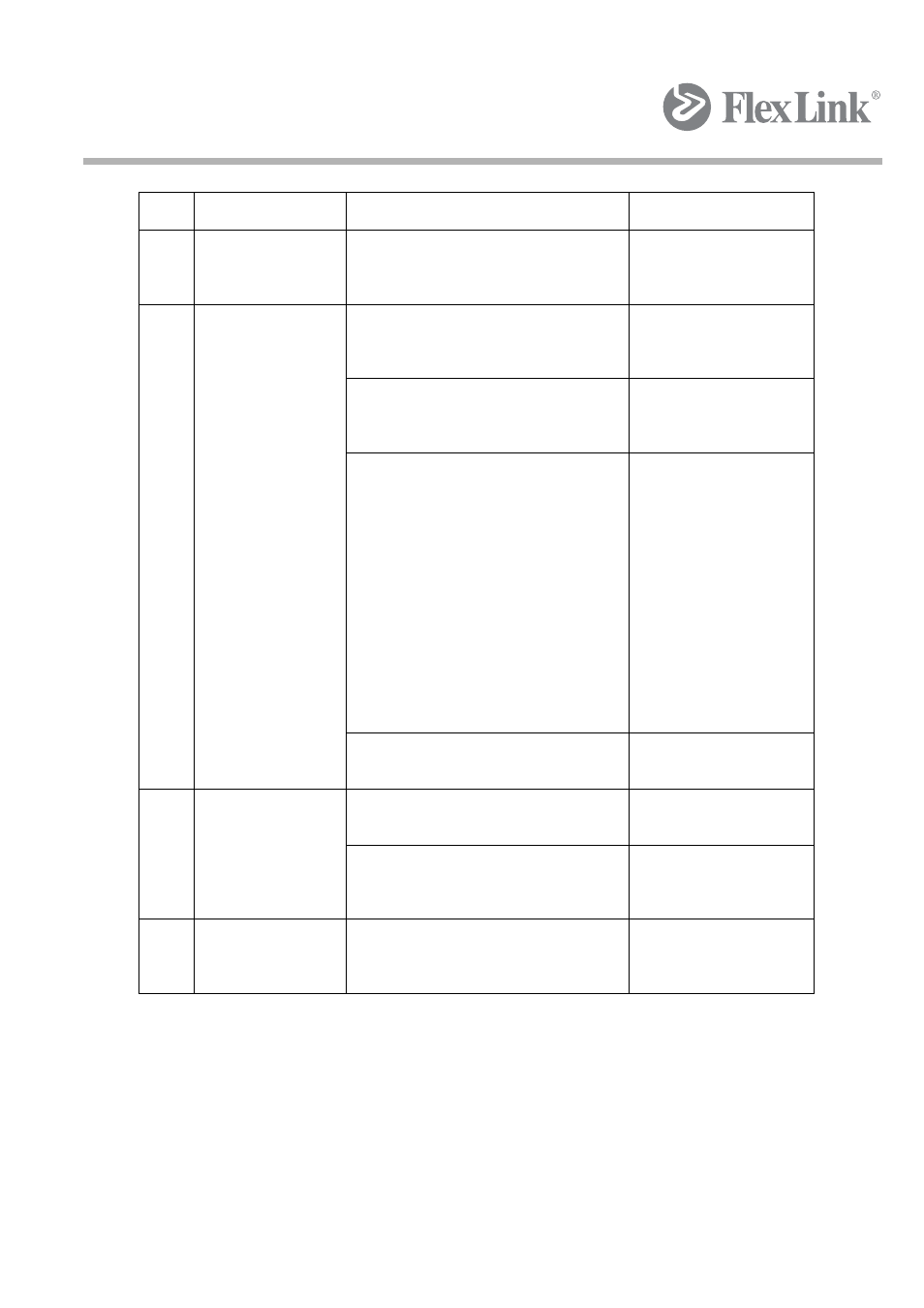

4.

Product stops as a

result of defective

conveyor plates

Missing or defective conveyor plate. Replace

conveyor

plate

(see Section 6.2 on

page 47).

5.

Product stops at

beginning or end of

Spiral Elevator

Product orientation

Check cause of

products incorrect

orientation.

Defective transition roller arrangement

(if fitted)

Contact the supplier of

the FlexLink Spiral

Elevator.

The product is pushed to the outside,

because there is no space between

the products on the Spiral Elevator.

The feed rate of the

product is too high for

the Spiral Elevator

speed. Check to see if /

why the feed rate is

above the specification

or why the Spiral

Elevator speed is below

the specification.

Typically the products

should have a minimum

distance between of

25% of the product

length.

Poor alignment of the products

Align the product before

the Spiral Elevator.

6. Product

jams

under guide rail

Guide rails not set correctly

Set guide rails to correct

height.

Product height is too low for guide rail

Check if product is to

specification or contact

the supplier.

7.

Chain too long

Combination of speed and continuous

load of product stoppage

Shorten the chain (see

Section 6.2.3 on page

50)

No. Trouble

Possible

cause

Solution