3 troubleshooting list – FlexLink Spiral Elevator User Manual

Page 63

Technical maintenance

Create

d

by EBCCW

0

0

:06

Page 57 of 68

5478EN-3

6.3

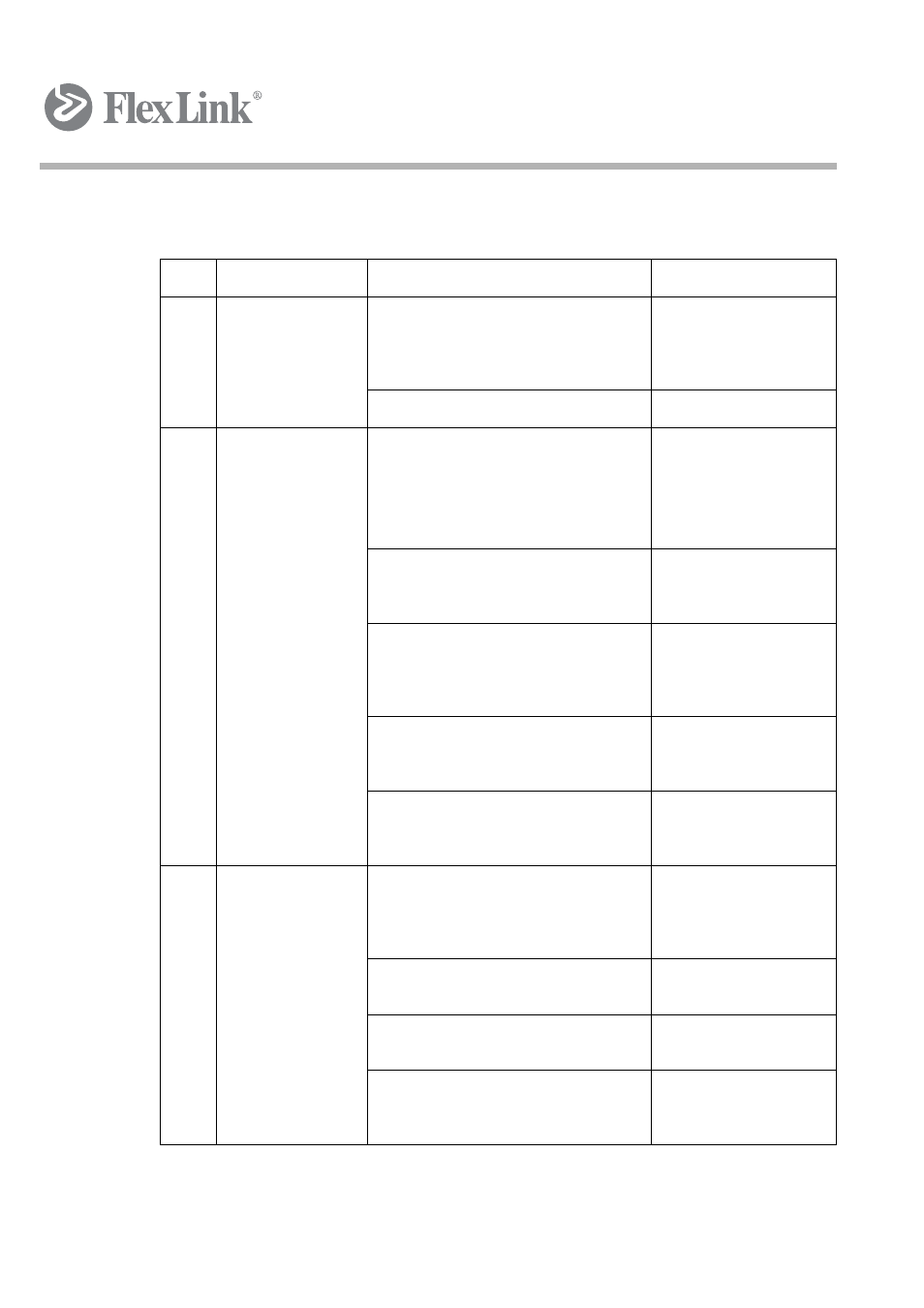

Troubleshooting list

No. Trouble

Possible

cause

Solution

1. Spiral

Elevator

does not work

No power (volts) at the gear motor

The cause for lack of

power to be

investigated by

qualified personnel.

Gear motor defective

Replace the motor

2. Spiral

Elevator

does not work, but

the motor is

running

Teeth on the sprocket wheel worn

Replace the sprocket

wheel.

It is recommended to

replace the entire chain

at the same time.

The metal chain is not located on the

sprocket

Realign the sprocket

and investigate the

cause.

Product jamming the Spiral Elevator

Remove the product

jam and check the width

/ height detectors (if

fitted).

Product weight overload / too much

product or weight on the Spiral

Elevator

Remove product and

operate within the

specification limits.

Metal chain broken

Repair or replace the

metal chain and check

sprockets.

3. Conveyor

plates

broken or

misaligned

Product jamming the Spiral Elevator

Remove the product

jam and check the width

/ height detectors (if

fitted).

Irregularities in the guide strips

Repair or replace the

relevant guide strip.

Foreign objects / material on conveyor

chain

Remove the foreign

objects or materials.

Chain too long, which makes the

plates grab at the entry to the

underside return guide

Shorten the chain (see

Section 6.2.3 on page

50).