Operator interface panel – Bell & Gossett S14367B Technologic Constant Speed Pump Controller User Manual

Page 9

Technologic

®

Constant Speed Pump Controller Installation, Operation and Maintenance Manual

9

Operator Interface Panel

2.2

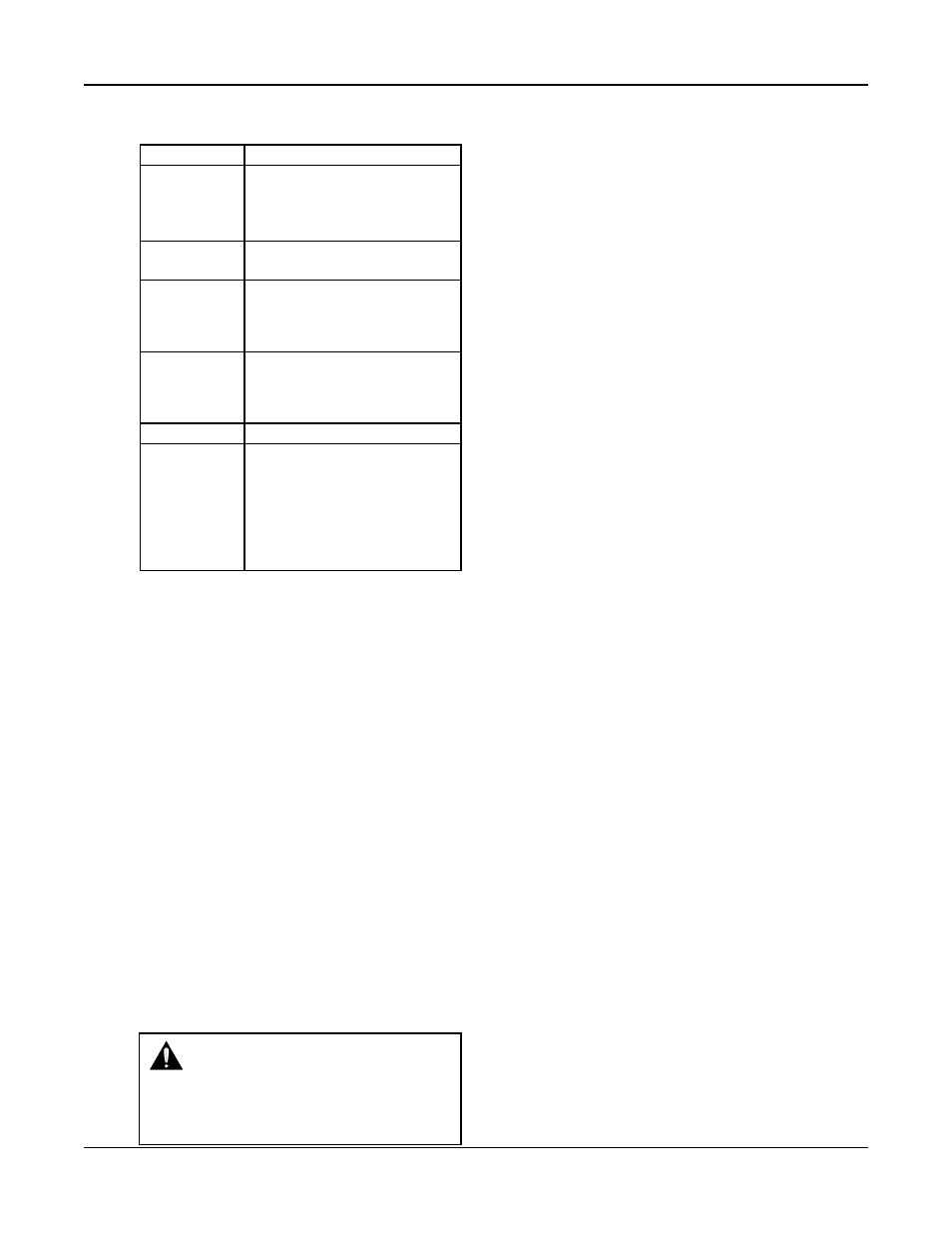

LEDs

Table 2 gives the meaning of the LED states.

LED

Description

START/STOP

On = Start

Off = Stop

Blink Slow = Ready (waiting for

remote method)

AUTO/

On = Auto

MANUAL

Off = Manual

PUMP 1-6

On = Pump On

Off = Pump Disabled

Blink Slow = Pump Ready

Blink Fast = Pump Failed

RESET/

Off = OK

SILENCE

Blink Slow = Reset Required

Blink Fast = A/V Alarm output

is active

LED

Description

HELP

Off = OK

Blink Slow = Event (press HELP

from the status

screens to view)

Blink Fast = Alarm (press HELP

from the status

screens to view)

Table 2: LED Functionality

2.3

I/O

2.3.1

Analog Inputs

The Technologic

®

Constant Speed Pump Controller

is equipped with 4 analog input channels. The analog

inputs must provide a 4-20mA signal. Typically, ana-

log inputs will be powered by the 24V power supply

within the panel. For analog inputs which source

their own power, see the following section. See sec-

tion 4.1 for more information on sensor setup.

Shielded 22 AWG cable should be installed for all

analog input wiring. The shield must be terminated

in the Technologic

®

Constant Speed Pump Controller.

Do not connect the shield at the other end of the

cable! Insulate the shield so that no electrical connec-

tion is made at the other end of the cable. A twisted

pair of #22 AWG conductors can be used in place of

shielded cable. The cable length must be limited to

5,000 feet for #22 AWG wire.

2.3.2

Powered Analog Inputs

The following steps describe the general procedure

for wiring an analog input when the sensor’s power

source is not the Technologic

®

Constant Speed Pump

Controller.

WARNING:

Prevent electrical shocks.

Disconnect the power supply before begin-

ning installation. FAILURE TO FOLLOW

THESE INSTRUCTIONS COULD RESULT IN

SERIOUS PERSONAL INJURY, DEATH AND/

OR PROPERTY DAMAGE.

1) Turn off all power to the Technologic

®

Constant

Speed Pump Controller.

2) Refer to the appropriate controller wiring diagram

that was shipped with unit. Locate the analog

input sensors on the wiring diagram that will be

rewired. They are labeled AI1 – AI4.

3) Remove the 24 VDC positive (+) wire from TB 40

for the respective analog input sensor connection.

This wire needs to be removed completely or ter-

minated if used as a jumper. This will prevent any

accidental contact with a negative (-) voltage

source (i.e. control panel) and avoid becoming a

short circuit. Care should be taken to ensure that

24 VDC positive (+) voltage is still provided to

any remaining sensors that will be powered by the

Technologic

®

Constant Speed Pump Controller.

4) Remove the 24 VDC negative (-) wire from TB 41

for the respective analog input sensor connection.

This wire needs to be removed completely or ter-

minated if used as a jumper. This will prevent any

accidental contact with a positive (+) voltage

source and avoid becoming a short circuit. Care

should be taken to ensure that 24 VDC (-) nega-

tive voltage is still provided to any remaining sen-

sors that will still be powered by the Technologic®

Constant Speed Pump Controller.

5) Terminate the negative (-) wire of the sensor to TB

41 of the respective analog input sensor connec-

tion. Terminate the positive (+) wire of the sensor

to the terminal block which is connected to the

positive (+) terminal shown on the Analog input

card.

Note: Be certain that the power supplied to other

terminal blocks has not been interrupted! The wires

that were removed in the preceding steps may have

been used as jumpers.

2.3.3

RTD Inputs

The Technologic

®

Constant Speed Pump Controller

is equipped with (2) PT100 RTD input channels. (2)

RTDs will be shipped with standard units. The sys-

tem RTD will be factory mounted, on the suction

header, unless the control panel is sold separate from

the pump package. The suction RTD will be shipped

loose inside the control panel and will need to be

field mounted upstream of the suction header.

2.3.4

Digital Inputs

The Technologic

®

Constant Speed Pump Controller

is equipped with (16) 24VDC digital input channels.

This signal voltage must be obtained from the 24VDC

power supply mounted to the subpanel. It is not rec-

ommended that other power sources be used without

factory approval. All digital inputs are automatically

assigned based on Table 3. See the typical wiring dia-

gram in Appendix H.