Parameter list – Bell & Gossett S14367B Technologic Constant Speed Pump Controller User Manual

Page 33

Technologic

®

Constant Speed Pump Controller Installation, Operation and Maintenance Manual

33

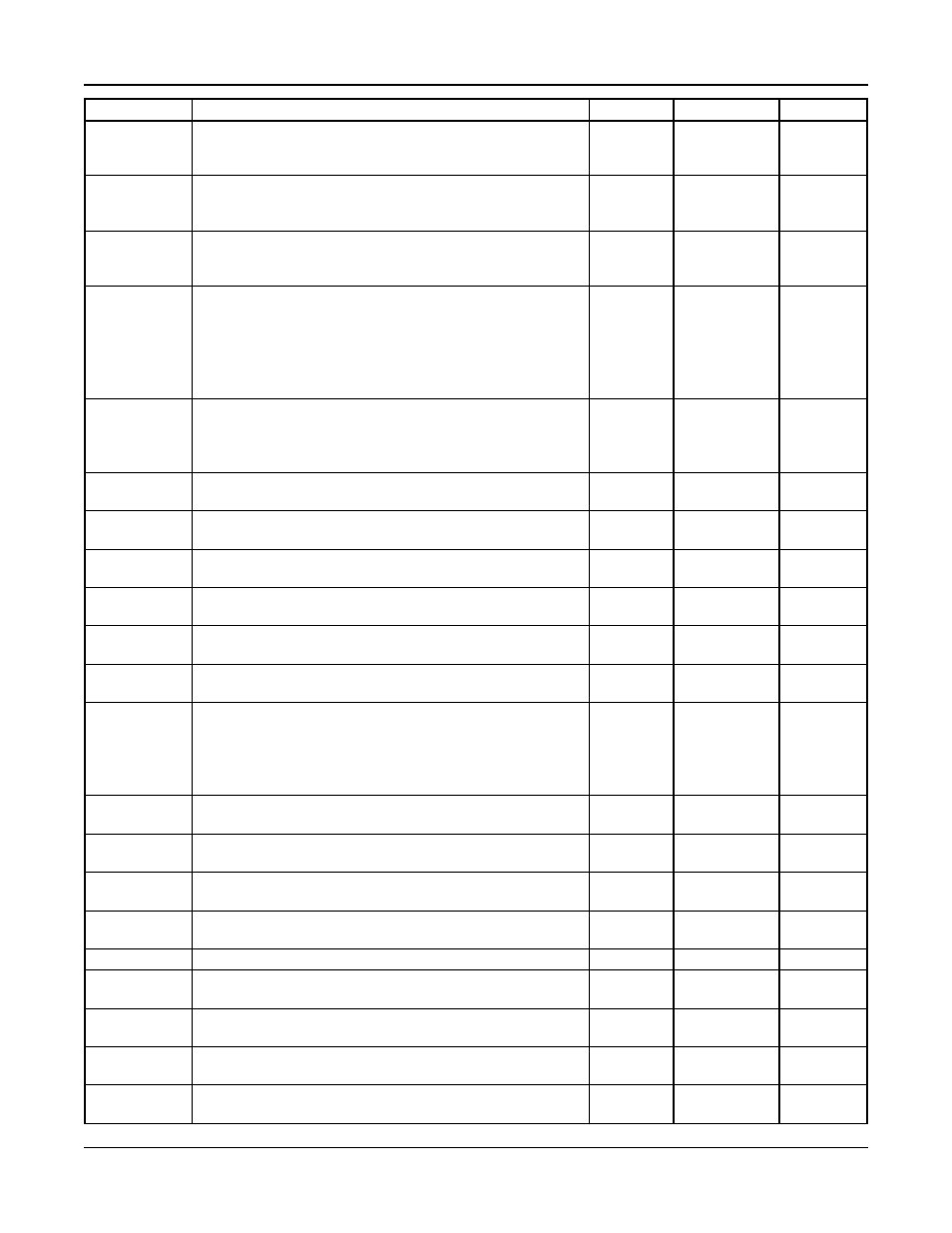

Parameter List

Variable

Description

Section

Default Value

Field Value

Dynamic Stg

Select “Y” for Dynamic Stg to choose different staging and

4.3.1.2

“N”

(secondary)

destaging values for each staging occurrence. A separate screen

will be displayed to allow for these inputs.

Force Dstg

Maximum time, in minutes, a lag pump will run prior to

4.3.1.3

60

Tmr

destaging automatically, a value of 0 disables forced destaging.

See section 3.4.5 for display of timer status.

Min Run

Minimum time, in minutes, a lag pump must run prior to

4.3.1.3

5

Timer

destaging, a value of 0 effectively disables the minimum run

timer. See section 3.4.5 for display of timer status.

Alt Method

Automatic Alternation Method

4.3.2

None

None: disables automatic alternation

Timed: alternates based on the “Period”

Daily: alternates daily based on the “Time”

Weekly: alternates weekly based on the “Time” and the “Day”

Monthly: alternates monthly based on the “Time” and the “Day”

Basis

Seq: the next pump in the sequence will become the lead pump 4.3.2

Seq

(Alternation)

after alternation

Pmp Tm: the pump with the lowest run time will become the

lead pump after alternation

Dur

Amount of time, in seconds, that the running pumps will

4.3.2

10

(Alternation)

remain on during alternation

Time

Time, in 24hr format, at which the pumps will be alternated

4.3.2

0:00

(Alternation)

for daily, weekly, or monthly alternation

Day

Day of the week (1=Monday…7=Sunday) or month (day of

4.3.2

1

(Alternation)

month) on which the pumps will be alternated

Period

Time, in hours, between pump alternations when using

4.3.2

168

(Alternation)

“Timed” alternation

Period

Time, in hours, between automatic exercising of the pumps,

4.3.3

0

(exercise)

a value of 0 disables pump exercising

Duration

Time, in seconds, pumps will be exercised, all pumps which

4.3.3

0

(exercise)

have not run in the last period will be exercised simultaneously

Start/stop

Keypad: Use the keypad to start and stop the system

4.3.4

Keypad

method

Remote: Use “Start/Stop Sw” tied to DI #7

Serial: Use “System Start/Stop” shown in appendix C

Scheduled: Use scheduling to start and stop the system,

see section 4.3.5

ON @

Time at which the system will automatically start. Set the hour 4.3.5

0:00 am

(Scheduling)

to 0 to prevent the system from starting on this day.

Off @

Time at which the system will automatically stop. Set the hour

4.3.5

0:00 am

(Scheduling)

to 0 to prevent the system from stopping on this day.

Relay Output

Relay output functionality for relays 1-8

4.3.8

1M-6M are

Functionality

factory set

Enable

This must be set to “Y” to utilize RS-485 communications.

4.3.10.1

Y

BACnet

It should only be set to “N” to upload software upgrades.

Baud

The baud rate is user adjustable

4.3.10.1

9600

MAC Address

The MAC address or node number should be supplied

4.3.10.1

10

by the BMS.

Inst

Unique instance numbers should be assigned for every device

4.3.10.1

100

on a BACnet network.

AI Ovrd

Select “Y” to override analog inputs through the

4.3.10.1

N

communications port. See section 4.3.10.5.

Enable Metasys This must be set to “Y” to utilize RS-485 communications.

4.3.10.2

Y

N2

It should only be set to “N” to upload software upgrades.