Operation – Bell & Gossett S14367B Technologic Constant Speed Pump Controller User Manual

Page 11

Technologic

®

Constant Speed Pump Controller Installation, Operation and Maintenance Manual

11

Operation

The CLEAR key is also used to exit some screens

including: Log screens, Test screens, Info screens, and

the Alarm screen.

3.3

Pump Operation

The pumps can be controlled manually or automati-

cally. See the following sections for instructions on

both types of operation.

3.3.1

Manual Pump Operation

To manually control the pumps with the controller,

the operation mode must be set to Manual by press-

ing the AUTO/MANUAL key. Note that this key is

not allowed unless the system is stopped. The Auto/

Manual LED will be off to indicate manual opera-

tion. The system must also be started by pressing the

START/STOP key. The Start/Stop LED will be on to

indicate the system is started.

Pumps are automatically disabled when operation

mode is changed to manual. Press the corresponding

PUMP ENABLE keys to start or stop pumps. The

corresponding LED will turn solid green to indicate a

pump is on.

3.3.2

Automatic Pump Operation

To automatically control the pumps with the control-

ler, the operation mode must be set to Auto by press-

ing the AUTO/MANUAL key. Note that this key is

not allowed unless the system is stopped. The Auto/

Manual LED will be on to indicate automatic opera-

tion. The system must also be started by pressing the

START/STOP key. The Start/Stop LED will be on to

indicate the system is started.

During automatic pump operation, the pumps will

turn on or off based on the primary staging method.

If more pumps are required to meet the system

demand, they will stage on as required. When the

system demand is met, and the minimum pump run

timer is met, the pumps will destage until only one

pump is running. When there is no demand in the

system, the no flow shutdown alarm or event will

occur, shutting down the last running pump. During

this sequence, alarms may occur that shut down a

specific pump or all of the pumps. Various automatic

pump alternation methods may be used to alternate

the pump sequence at any time.

View the status screens, shown in section 3.4, to get

system information including on/off or auto/manual

status, pump status, sensor values, or staging status.

3.4

Status Screens

The status screens are the main level in screen naviga-

tion and show most of the relevant system informa-

tion. The status screens can be scrolled by pressing

PREV or NEXT.

The Setup Menu(3), Log Menu(5), Info screens(8),

Manual Alternation screen(9), and Alarm

screen(HELP) are only accessible from the status

screens.

All of the status screens will display “Alm”, “Evt”, or

“NFSD” in the lower right corner if an alarm or

event or NFSD condition exists. If this message is

flashing, press the HELP key for more details.

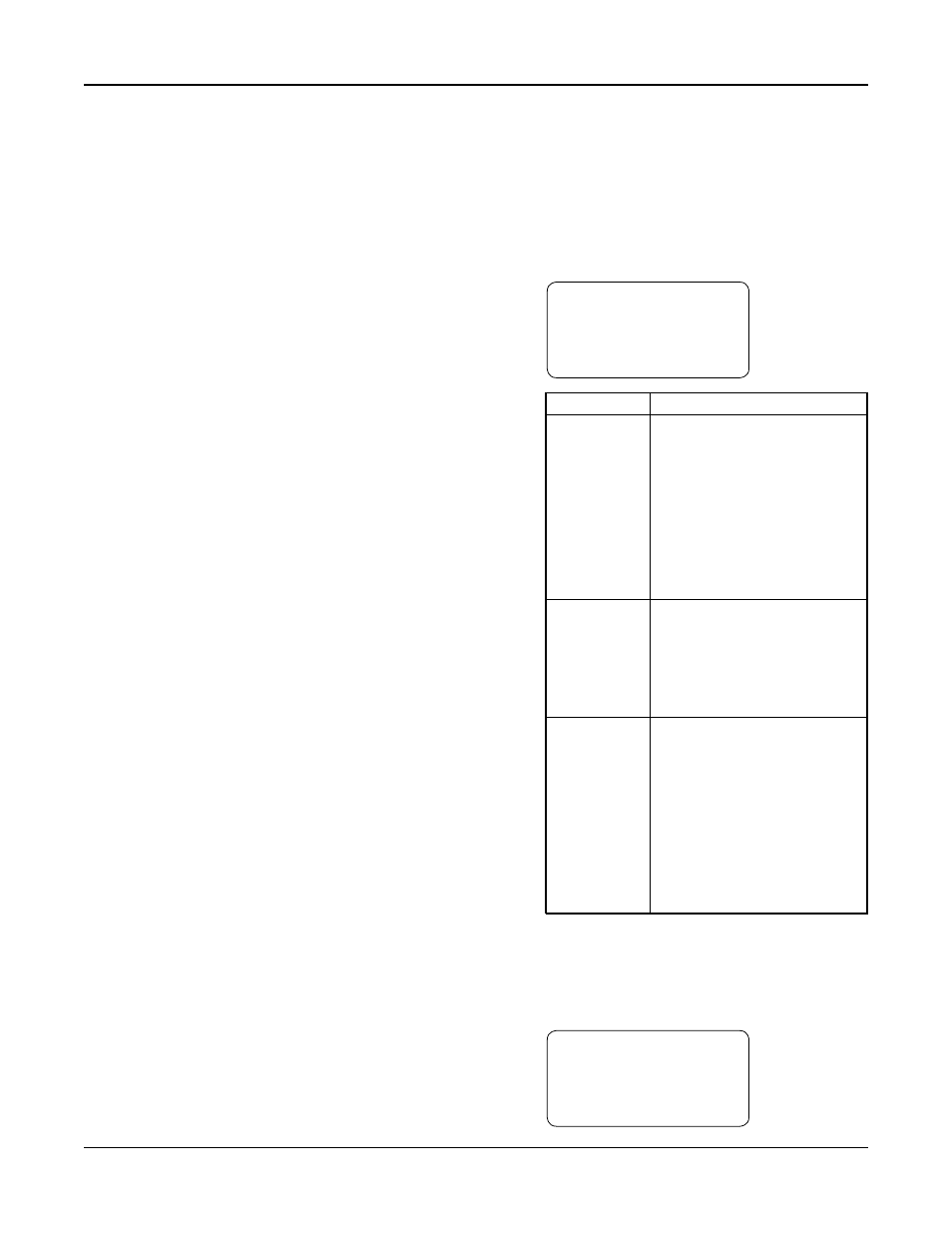

3.4.1

Tech Status

The Tech Status screen, shown below, is the first of

the status screens. This screen is displayed on power

up. See Table 4 below for a description of the Tech

Status variables.

←

TECH STATUS →

HH:MMam MM/DD/YY

Stop :(Method)

Manual Alm

Variable

Description

Start/Stop/

Stop: System is stopped. Pumps

Ready

will not start.

Start: System is started. The

pumps can be controlled manually

or automatically.

Ready: System is waiting for

remote start/stop method,

see section 4.3.4.

Press the START/STOP button

to toggle.

Method

System Start/Stop Method, see

section 4.3.4.

Key: Keypad

Rem: Remote contact

Sch: Scheduled start/stop

Ser: Serial Communications

Auto/Manual

Manual: System is in manual

operation mode. The user can

manually start and stop the pumps

by pressing the corresponding

Pump On/Off key.

Auto: The system is in automatic

operation mode. The pumps will

be controlled automatically based

on the user setup info.

Press the AUTO/MANUAL key

to toggle.

Table 4: Tech Status Variables

3.4.2

Pump Status

Pressing NEXT, the controller will display the Pump

Status screen shown below. See Table 5 for a descrip-

tion of the Pump Status variables.

←

PUMP STATUS →

1:On 2:On 3:Off

4:Rdy 5:Fail 6:Rdy

Alm