Setup menu – Bell & Gossett S14367B Technologic Constant Speed Pump Controller User Manual

Page 18

Technologic

®

Constant Speed Pump Controller Installation, Operation and Maintenance Manual

18

Setup Menu

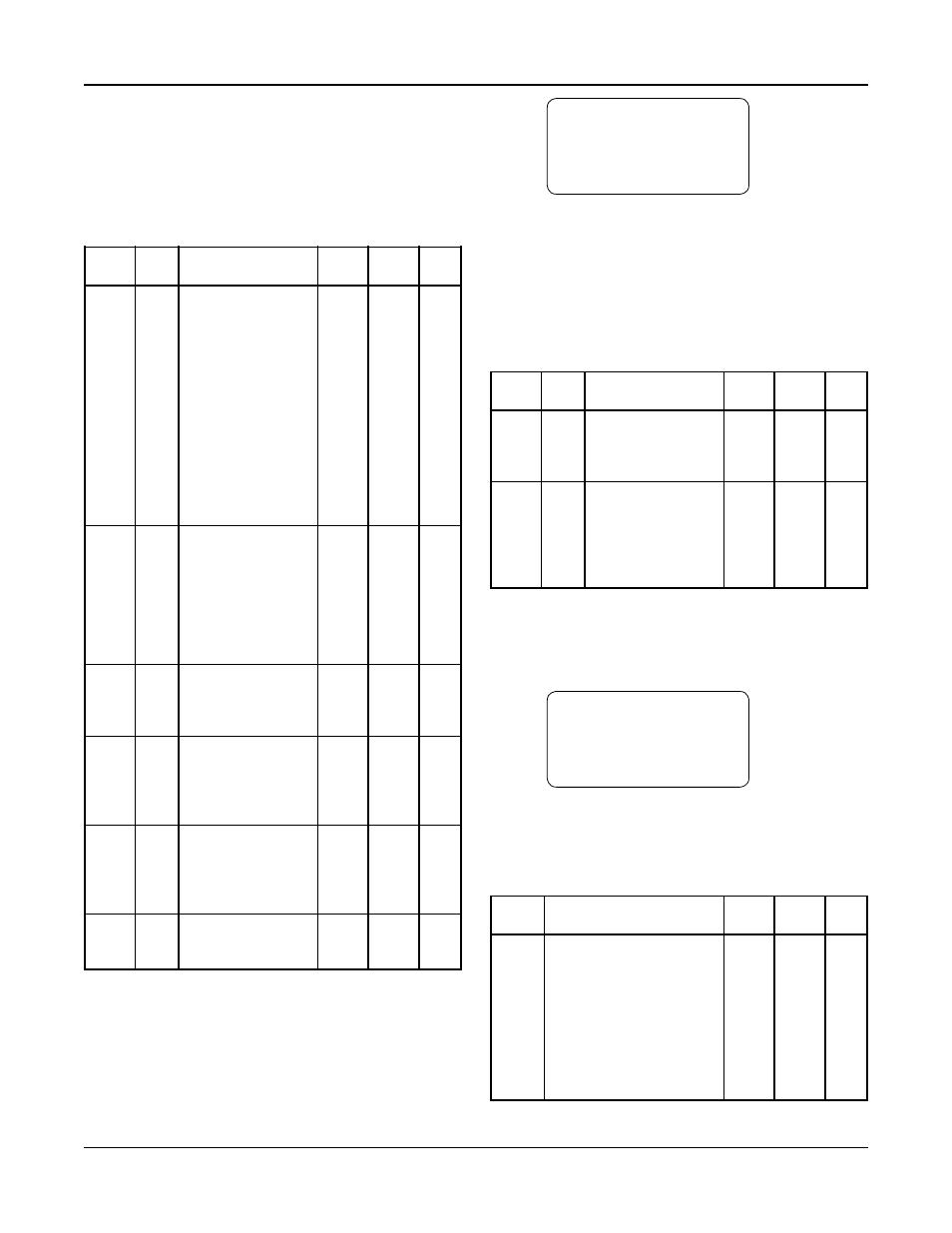

The pump staging sequence, which is shown in sec-

tion 3.4.4, may be alternated automatically or manu-

ally. To manually alternate the sequence, press ALT

from the status screens, then press “Y” and ENTER

at the prompt. Automatic and manual alternation

methods use the Basis and Dur variables shown

below. See Table 19 for a description of the

Alternation variables.

Variable Units Description

Default Range Field

Value

Value

Alt

N/A Automatic Alter-

None None,

nation Method

Timed,

None: disables

Daily,

automatic alternation

Weekly,

Timed: alternates

Monthly

based on the “Period”

Daily: alternates daily

based on the “Time”

Weekly: alternates

weekly based on the

“Time” and the “Day”

Monthly: alternates

monthly based on the

“Time” and the “Day”

Basis

N/A Seq: the next pump in

Seq

Seq,

the sequence will

Pmp

become the lead pump

Tm

after alternation

Pmp Tm: the pump

with the lowest run time

will become the lead

pump after alternation

Dur

Sec- Amount of time that

10

0-99

onds the running pumps will

remain on during

alternation

Time

N/A Time, in 24hr format,

0:00

0:00-

at which the pumps will

23:59

be alternated for daily,

weekly, or monthly

alternation

Day

N/A Day of the week (1=

1

1-28

Monday…7=Sunday)

or month (day of month)

on which the pumps

will be alternated

Period Hours Time between pump

168

0-999

alternations when using

“Timed” alternation

Table 19: Alternation Variables

4.3.3

Pump Exercise

Path: Status Screens / Setup (3) / System (3) /

Exercise (3)

Pump Exercise

Period : ###Hr

Duration : ###Sec

OK? $

Pump exercising will ensure that no pumps go for

long periods of time without running. Note that

automatic alternation can also provide this function-

ality. Pump exercising will only occur when the sys-

tem is started and in automatic operation. All pumps

which need exercising will exercise on startup. All

exercising events will be logged in the Exercise Log

shown in section 4.7.5.5. See Table 20 for a descrip-

tion of the Exercise variables.

Variable Units Description

Default Range Field

Value

Value

Period Hours Amount of time between

0

0-999

automatic exercising of

the pumps, a value of 0

disables pump exercising

Dur-

Sec- Amount of time pumps

0

0-999

ation

onds will be exercised, all

pumps which have not

run in the last period

will be exercised

simultaneously

Table 20: Pump Exercise Variables

4.3.4

Start/Stop

Path: Status Screens / Setup (3) / System (3) / Start /

Stop (4)

Start/Stop

Method: $$$$$$$$$

OK? $

The controller can be started or stopped in a variety

of ways. This method will always be displayed next

to the start/stop/ready status in the Tech Status screen

shown in section 3.4.1. See Table 21 for a description

of the Start/Stop Methods.

Variable Description

Default Range Field

Value

Value

Method Keypad: Use the keypad to

Keypad Keypad,

start and stop the system

Remote,

Remote: Use “Start/Stop

Serial,

Sw” tied to DI #7

Sched-

Serial: Use “System Start/

uled

Stop” shown in appendix C

Scheduled: Use scheduling

to start and stop the system,

see section 4.3.5

Table 21: Start/Stop Variables