Operator interface panel – Bell & Gossett S14367B Technologic Constant Speed Pump Controller User Manual

Page 10

Technologic

®

Constant Speed Pump Controller Installation, Operation and Maintenance Manual

10

Operator Interface Panel

Functionality

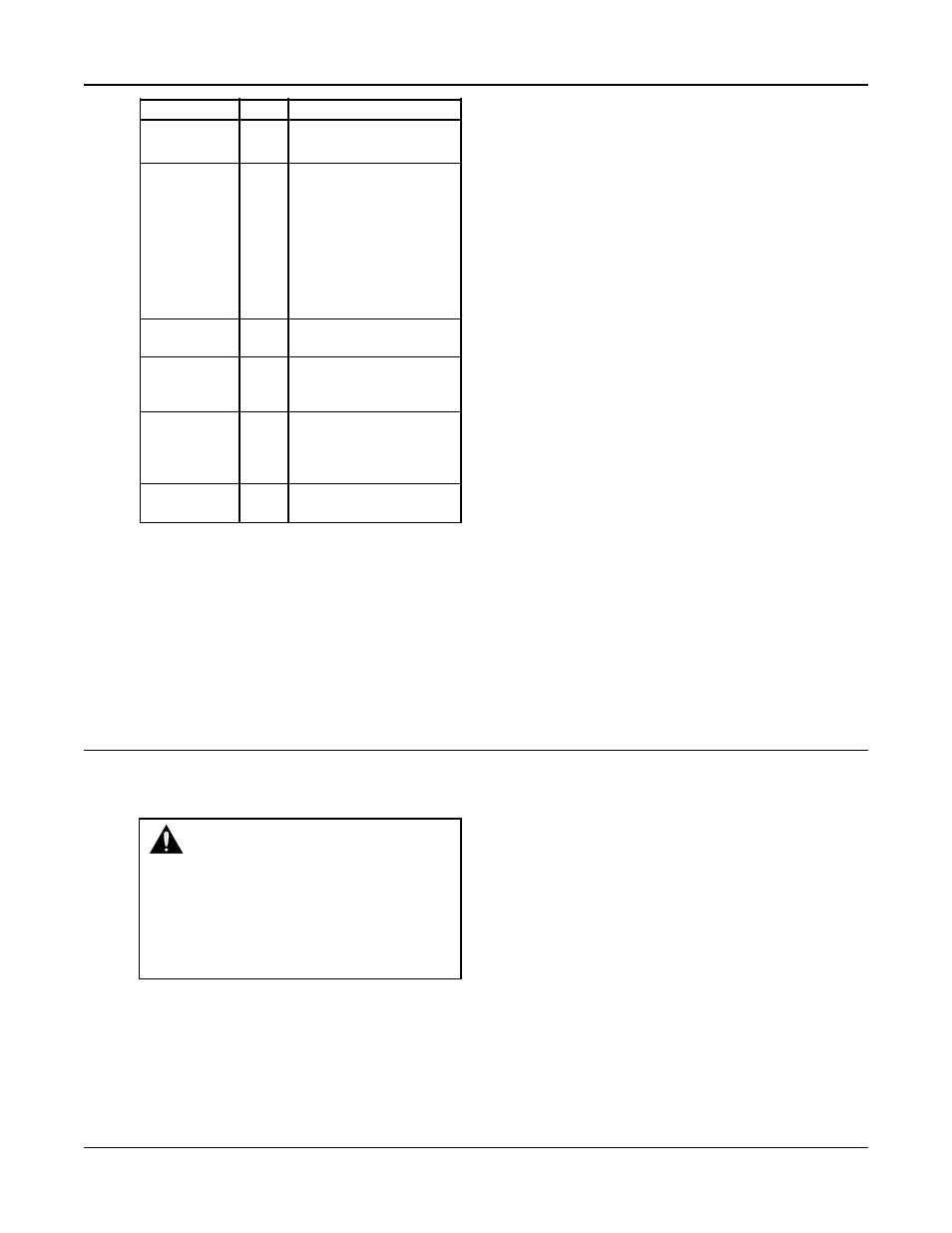

DI # Description

1M-6M

1-6

Motor starter feedbacks

Feedback

(generate overload alarm)

Start/Stop Sw

7

Remote contact can be

used to start/stop the

system. The start/stop

method must be set to

Remote. See section 4.3.4.

“Rem” will be displayed in

the Tech Status screen

shown in section 3.4.1

when this method is active.

Flow Switch

8

Used for no flow shut-

down, see section 4.5.6.

Pressure Sw

9

Used to detect low suction

pressure alarm or event,

see section 4.5.4.

Low Level

10

Low level relay to sense a

low level condition in a

tank. All pumps will stop

when active.

DP 1-6

11-16 Differential pressure

switches

Table 3: Digital Inputs Functionalities

# 22 AWG cable should be installed for all field wir-

ing to digital inputs.

2.3.5

Relay and Power Monitor Rack

The relay and power monitor rack consists of an

EX270 CAN bus controller, a DO722 digital output

module and an AI984 power measurement module.

2.3.5.1 Digital Output Module

The digital output module consists of 8 normally

open single pole single throw relays rated at 2.5A at

either 240VAC or 24VDC. One relay will be used to

energize the coil of each motor starter. These will be

factory wired. Customer connections are made direct-

ly to the terminals mounted on the digital output

module. If a relay is defective, the digital output

module must be replaced. Refer to section 4.3.8 for

relay output setup.

2.3.5.2 Power Measurement Module

The power measurement module calculates total

power by measuring the incoming voltage and the

total current from the current transformer.

2.3.5.3 Current Transformer

The current transformer (ct) comes in three different

sizes measuring up to 40A, 150A, or 400A. It plugs

directly into the AI984 module on the relay and

power monitor rack. The ct measures the total amp

draw of all motors in the system. The four digit hex

numbers displayed on the label on the current trans-

former are calibration values, unique to each ct, that

have been input into the controller prior to shipment.

See section 5.5 to view the values used.

Section 3 — Operation

3.1

Power-Up

Turn the disconnect switch “ON” to power up the controller.

WARNING:

Electrical shock hazard.

Inspect all electrical connections prior to

powering the unit. Wiring connections must be

made by a qualified electrician in accordance with

all applicable codes, ordinances and good practic-

es. FAILURE TO FOLLOW THESE INSTRUC-

TIONS COULD RESULT IN SERIOUS

PERSONAL INJURY, DEATH AND/OR

PROPERTY DAMAGE.

In order to recover from a power loss, the controller

will start up in the operating mode that it was in

prior to the last shutdown. On power up, the con-

troller will display the Tech Status screen shown in

section 3.4.1.

3.2

Basics of Screen Navigation and User

Setup

Numeric inputs (represented by the # symbol) must

be input from the numeric keypad. Text fields (repre-

sented by the $ symbol) must be modified by using

the UP and DOWN arrow keys. For numeric or text

fields, ENTER must be pressed to confirm values.

The arrow keys are also be used to navigate to neigh-

boring screens. Flashing arrows shown on the display

indicate when the corresponding arrow keys are

active.

An OK prompt is used in most user setup screens.

Press NO (the number 4 key) followed by ENTER at

the OK prompt to edit the parameters shown, or

press YES (the number 1 key) followed by ENTER to

accept the values and exit the screen.

The YES/1 and NO/4 keys are also used for text

inputs for some parameters. They will appear as “Y”

or “N” when a text input is required.