Setup menu – Bell & Gossett S14367B Technologic Constant Speed Pump Controller User Manual

Page 27

Technologic

®

Constant Speed Pump Controller Installation, Operation and Maintenance Manual

27

Setup Menu

4.7

Log Menu

Path: Status Screens / Log (5)

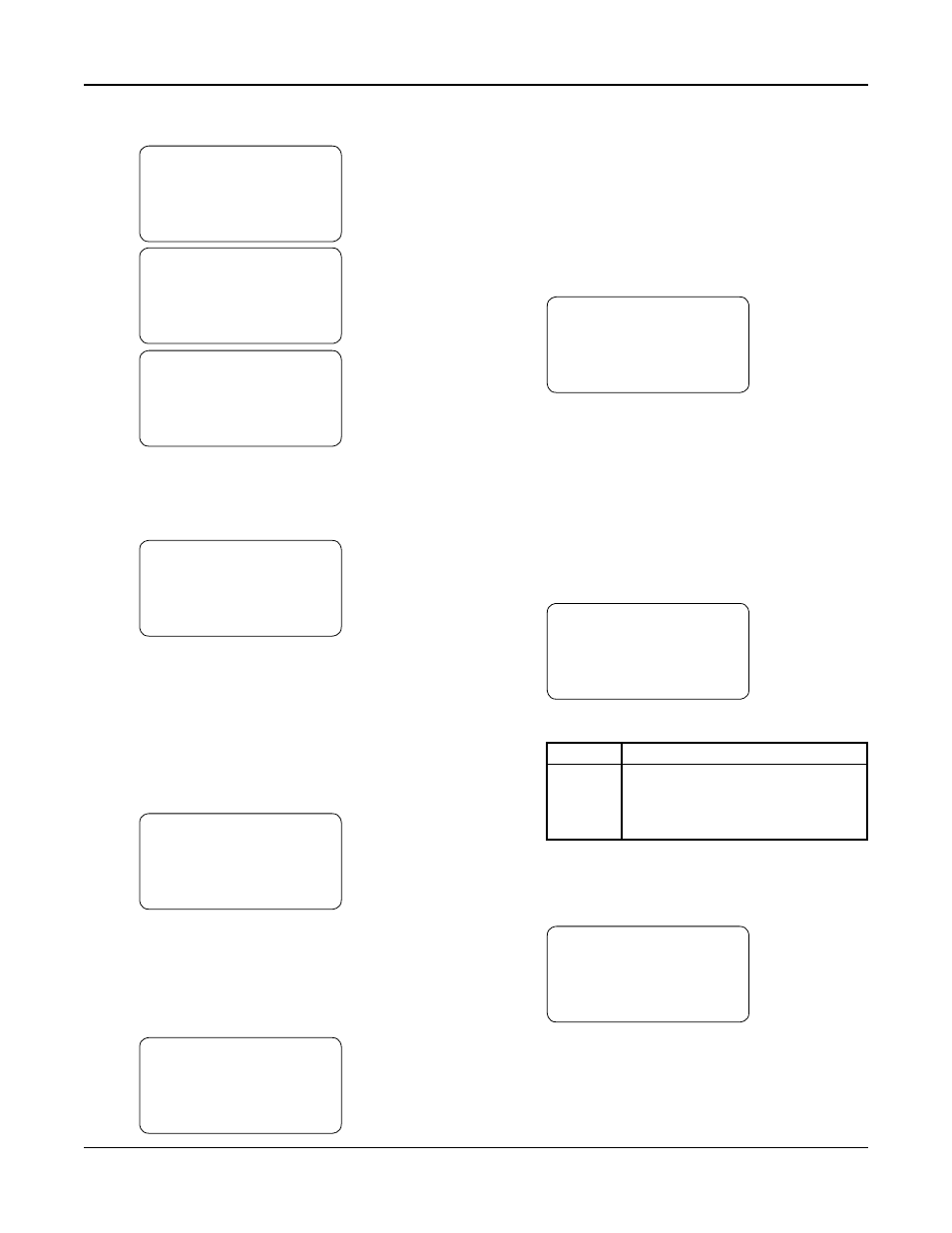

Log Menu: # 0=Exit ↑

1=Alarm Log

2=Pump Log Menu

3=Data Log

↓

Log Menu: # 0=Exit ↑

4=Data Log Rate

5=Operation Menu

6=Totals

↓

Log Menu: # 0=Exit ↑

7=Reset Totals

8=Log Book

↓

Press UP/DOWN to view the entire menu.

4.7.1

Alarm Log

Path: Status Screens / Log (5) / Alarm Log (1)

MMDD HHMM (alarm)

MMDD HHMM (alarm)

MMDD HHMM (alarm)

MMDD HHMM (alarm)

Every alarm that occurs will be logged with a date

and time stamp. The forty most recent alarms will be

stored. The date is displayed in MMDD format and

the time in 24 hour HHMM format. The most recent

alarm is shown first. Press UP and DOWN to view

more log events. Press CLEAR to exit.

4.7.2

Pump Log Menu

Path: Status Screens / Log (5) / Pump Log Menu (2)

Pump Log:# 0=Exit

1=Pump State

2=Pump Runtime

3=Reset Pmp Runtime

Press the numeric key corresponding to the desired

sub-menu, and press ENTER.

4.7.2.1 Pump State Log

Path: Status Screens / Log (5) / Pump Log Menu (2) /

Pump State (1)

Pump State

Pump # 1

MM/DD

(state)

HH/MM

Scr# 1

Each time a pump’s state changes, the date and time

are recorded along with the new pump state. The

sixty most recent pump state changes will be stored.

Possible states are ON, RDY, OFF, and FAIL. The

date is displayed in MMDD format and the time in

24 hour HHMM format. Press UP/DOWN to view

more log events. Press CLEAR to exit.

4.7.2.2 Pump Runtime Log

Path: Status Screens / Log (5) / Pump Log Menu (2) /

Pump Runtime (2)

Pump Run Time Log

P1:### P2:### P3:###

P4:### P5:### P6:###

OK? $ (Y/N)

The pump runtimes may be used to automatically

alternate the pump staging sequence so that the pump

with the lowest runtime will be the lead pump. See

section 4.3.2 for more information on alternation.

The runtime is continuously recorded for each pump

and is displayed in hours. To reset the pump runtimes

see section 4.7.2.3.

4.7.2.3 Reset Pump Runtime

Path: Status Screens / Log (5) / Pump Log Menu (2) /

Reset Pmp Runtime (3)

Reset Pump Runtime?

P1:$ P2:$ P3:$

P4:$ P5:$ P6:$

OK? $ (Y/N)

See Table 39 for a description of the variables.

Variable Description

P1-P6

Enter a “Y” next to each pump for

which the runtime will be reset. To

view the pump runtimes, see section

4.7.2.2.

Table 39: Reset Pump Runtime

4.7.3

Data Log

Path: Status Screens / Log (5) / Data Log (3)

AI/RTD#

(Type)

Max=#####

MM/DD

Min=#####

HH:MM

Avg=#####

Scr# 1

The Data Log screen will show the minimum, maxi-

mum and average values for each analog input and

RTD input channel. The sixty most recent data log

intervals will be stored. The analog input or RTD

channel along with the type of sensor set up for that

channel will be displayed on the top line. Press NEXT