Maintenance – Bell & Gossett S14367B Technologic Constant Speed Pump Controller User Manual

Page 31

Technologic

®

Constant Speed Pump Controller Installation, Operation and Maintenance Manual

31

Maintenance

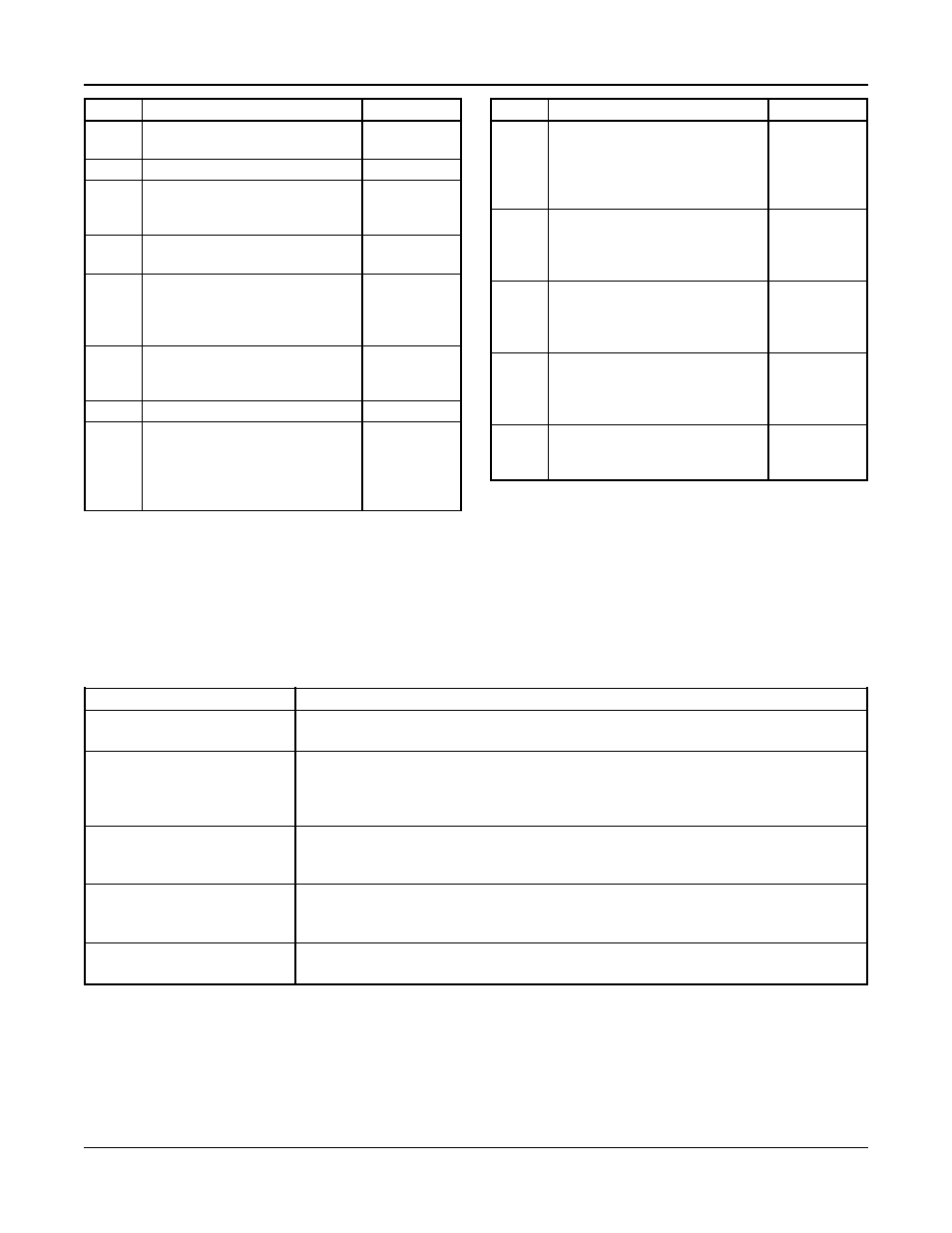

Variable Description

Range

Job #

QM or QB

service calls

0000-9999

Ver

Software version number

1.0 – 9.99

Volts

Incoming Voltage, used as the

208/230/

nominal value for the voltage

460/575

tolerance alarm

App

Application type (70E = open

70E/350

system, 350 = closed system)

Comms Serial communication protocol

BACnet,

Modbus,

JC N2,

Lonworks

3Φ

“Y” should be selected for three

Y/N

phase voltage and “N” should be

selected for single phase.

Suc Pr Suction Pressure

0-999

Sys Pr System Pressure, used to set default 0-999

alarm values for high suction

pressure, low system pressure, high

system pressure, and the restart

PSI for no flow shutdown

Variable Description

Range

#

Number of pumps that were

1-6

Pumps entered by the factory (Total

number, number of jockey pumps,

number of standby pumps), see

section 4.2.1.

CT

Size of the current transformer in 40, 150, 400

amps, this must be correct for

proper amp and power

measurement.

G

Gain for CT calibration (printed

Hex values

on the label on the CT), this must 0-F

be correct for proper amp and

power measurement.

O

Offset for CT calibration (printed Hex values

on the label on the CT), this must 0-F

be correct for proper amp and

power measurement.

HP1-6 Horsepower for each pump that

0-999.9

was entered by the factory, see

section 4.2.2.

Table 43: Info Screens Variables

Note: There are redundant setup screens for horse-

power and number of pumps. The values entered

here are used to set default values only. The actual

parameters used for operation are shown in section

4.2 and may be different than the values shown here.

5.6

Troubleshooting

Problem

Solution

Service Mode LED

Set the node switches on the controller to 0 and 0 and cycle power. Set the node switches

(blank screen)

back to 1 and 1 and cycle power again.

Pump won’t start

Check that the Start/Stop LED is on. Check that the pump status LEDs are blinking to

indicate that they are ready. Press the HELP key from the status screens to check the alarm

screen for any conditions that may prevent the pumps from running. If the RESET/

SILENCE LED is flashing, a manual reset of the system is required.

Pumps won’t stage on/off

Check the Staging screen to see what the staging method is and what the next staging values

are. See section 3.4.4. Check the timers screen to be sure that the pump minimum run timer

is expired prior to destaging. See section 3.4.5.

No Flow Shutdown will

Check the Timers screen to be sure that the NFSD minimum run time has expired. Only

not occur

one pump must be running and the system pressure must be greater than the NFSD restart

pressure in order for NFSD to occur. See section 4.5.6.

Inaccurate amps, voltage

Check that the calibration values printed on the label on the current transformer correspond

or power readings

to the values shown in the Info screens. See section 5.5.

Job #, this will be helpful for