1 key functionality – Bell & Gossett S14367B Technologic Constant Speed Pump Controller User Manual

Page 8

Technologic

®

Constant Speed Pump Controller Installation, Operation and Maintenance Manual

8

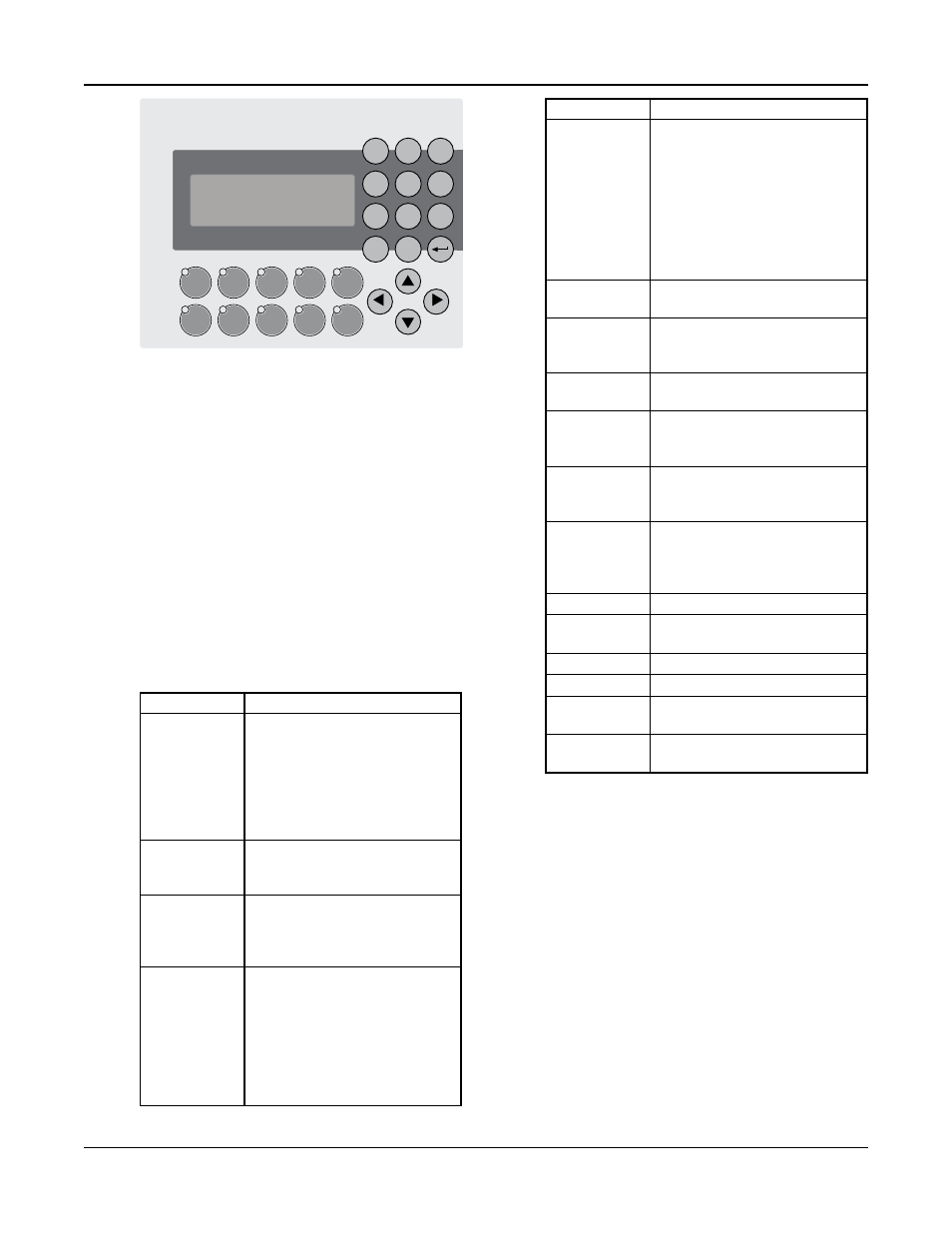

The OIP consists of a 4 x 20 character LCD screen

and a 26 button keypad with LEDs which display sys-

tem status. It also is equipped with onboard I/O

including (16) 24VDC digital inputs, (4) 4-20mA

analog inputs, (2) PT100 RTD inputs, and an RS232/

RS485 serial port for communications all mounted

on the back of the OIP. The OIP communicates

through a CAN bus to the relay and power monitor

rack.

2.1

Key Functionality

The names of the keys on the Operator Interface

Panel (OIP) are shown as CAPITAL LETTERS in this

manual. Table 1 shows the functionality of the keys

on the OIP.

Note: The contrast can be adjusted from any screen

by pressing the UP and DOWN arrows while holding

the ENTER key.

Key Name

Functionality

START/STOP

Starts or stops the system. When

the Start/Stop method is not

“Keypad”, pressing the START/

STOP key will toggle between

“Ready” and “Stop”. “Ready”

indicates the system is waiting

for a remote signal to start.

AUTO/

Toggles the operation mode. The

MANUAL

system must be stopped to

change the operation mode.

PUMP 1-6

Enables or disables the

ENABLE

corresponding pump. Pumps

cannot be disabled while they

are failed.

RESET/

This key is used to reset pumps

SILENCE

and alarms. When the A/V Alarm

relay output (section 4.3.8) is

set, initial pressing of this key

opens the relay to silence the

horn or turn off the pilot light.

Pressing a second time resets the

pumps and alarms.

Key Name

Functionality

HELP

Press the HELP button, from the

status screens, to view alarms or

events while the HELP LED is

flashing. While in the Alarm

screen, press the HELP button

again to view help messages for

active alarms. Press HELP any

other time to view screen

specific help messages.

YES/1

Press YES at OK prompts to

accept values and proceed

SETUP/3

Press SETUP, from the status

screens, to bring up the Setup

Menu shown in section 4

NO/4

Press NO at OK prompts to edit

the parameters

LOG/5

Press LOG, from the status

screens, to bring up the Log

Menu, shown in section 4.7

INFO/8

Press INFO, from the status

screens, to bring up the Info

screens, shown in section 5.5

ALT/9

Press ALT, from the status

screens, to manually alternate

the pump staging sequence, see

section 4.3.2

ENTER

Confirms entries

CLEAR

Clears entries or used to exit

some screens

PREV (←)

Navigates to neighboring screens

NEXT (→)

Navigates to neighboring screens

UP (↑)

Used to modify values and

navigate to neighboring screens

DOWN (↓)

Used to modify values and

navigate to neighboring screens

Table 1: Key Functionality

1

Yes

2

3

Setup

4

No

5

Log

6

7

8

Info

9

Alt

Clear

0

Enter

Technologic

®

Constant Speed Pump Controller

Next

Prev

GREEN = RUN

OFF = STOP

GREEN = AUTO

OFF = MANUAL

ON SOLID-PUMP RUNNING

OFF-PUMP DISABLED

FLASH SLOW-PUMP READY

FLASH FAST-PUMP FAILED

Start /

Stop

Pump 1

Enabled

Pump 2

Enabled

Pump 3

Enabled

Reset /

Silence

Auto /

Manual

Pump 4

Enabled

Pump 5

Enabled

Pump 6

Enabled

Help

Section 2 — Operator Interface Panel