Bell & Gossett S14367B Technologic Constant Speed Pump Controller User Manual

Page 32

Technologic

®

Constant Speed Pump Controller Installation, Operation and Maintenance Manual

32

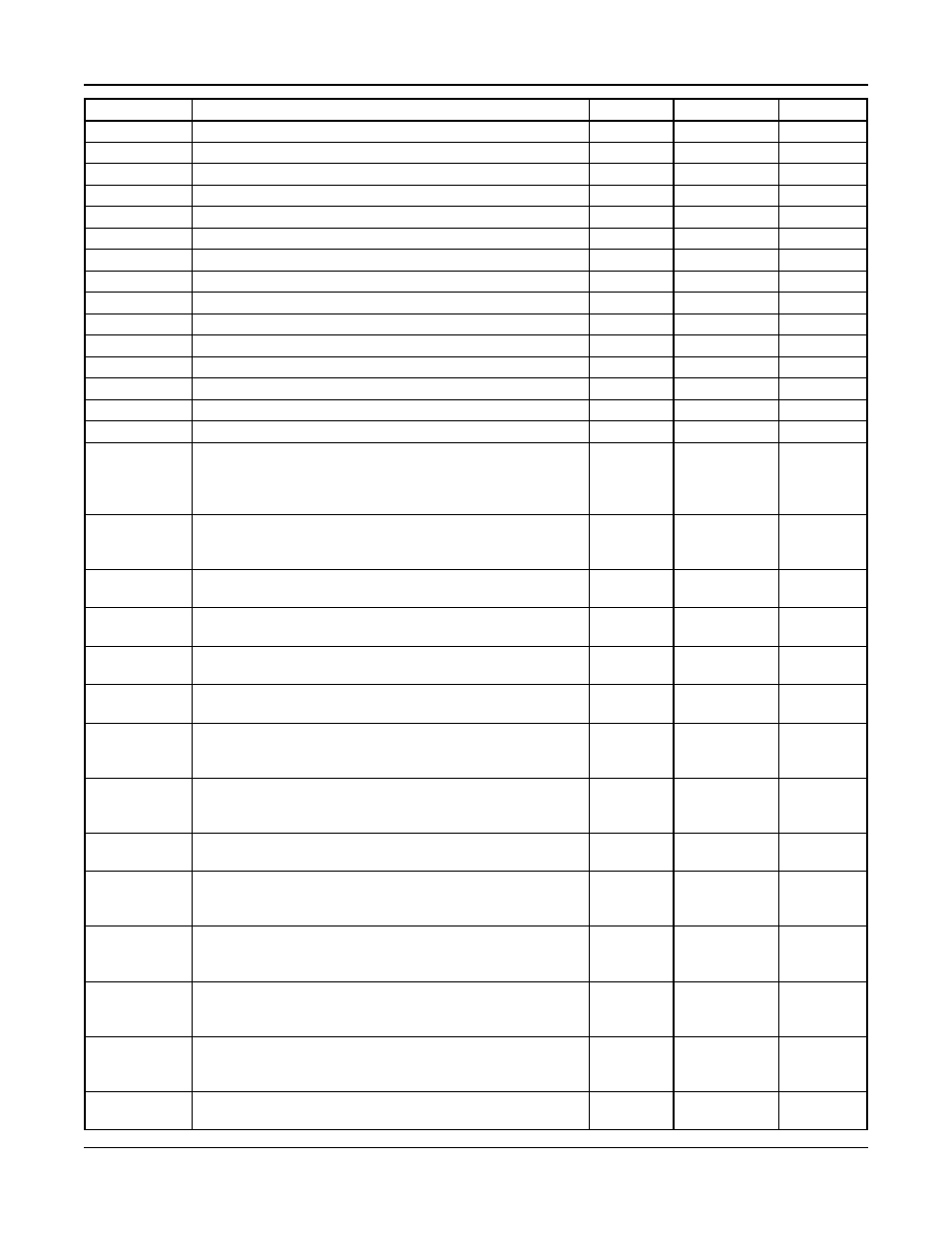

Variable

Description

Section

Default Value

Field Value

AI #1 Type

Type of sensor connected to this channel

4.1

Suc Press

AI#1 Span

Sensor value that corresponds to a 20mA signal

4.1

100

AI#1 Zero

Sensor value that corresponds to a 4mA signal

4.1

0

AI #2 Type

Type of sensor connected to this channel

4.1

Sys Press

AI #2 Span

Sensor value that corresponds to a 20mA signal

4.1

300

AI #2 Zero

Sensor value that corresponds to a 4mA signal

4.1

0

AI #3 Type

Type of sensor connected to this channel

4.1

None

AI #3 Span

Sensor value that corresponds to a 20mA signal

4.1

0

AI #3 Zero

Sensor value that corresponds to a 4mA signal

4.1

0

AI #4 Type

Type of sensor connected to this channel

4.1

None

AI #4 Span

Sensor value that corresponds to a 20mA signal

4.1

0

AI #4 Zero

Sensor value that corresponds to a 4mA signal

4.1

0

RTD #1 Type

Type of RTD connected to this channel

4.1

Suc Temp

RTD #2 Type

Type of RTD connected to this channel

4.1

Sys Temp

Total # Pumps The total number of pumps in the system.

4.2.1

Factory Set

# Jockey

Jockey pumps will always be first in the staging sequence.

4.2.1

0

Pumps

Alternation will not change this designation. Jockey Pumps

will be assigned to the lowest pump numbers starting with

Pump # 1.

# Standby

A standby pump will only operate if a duty pump fails.

4.2.1

0

Pumps

The last pumps in the staging sequence will be designated

as the standby pumps.

HP

Enter the horsepower from the nameplate of the motor.

4.2.2

Actual

These values are required for power staging.

Amps

Enter the full load amps from the motor nameplate.

4.2.2

0

These values are required for amps staging.

GPM

Enter the maximum GPM from the pump nameplate.

4.2.2

0

These values are required for flow staging.

Pri Stg Mthd

Primary staging method. Power, Amps, and flow staging

4.3.1.1

Power

require nameplate data to be set up. See section 4.2.2.

Stg (primary)

The value at which pumps will stage on. The units depend on

4.3.1.1

80

the staging type. This is the stage 1-2 value and will be used for

each staging occurrence unless Dynamic Stg is set to “Y”.

Dstg (primary) The value at which pumps will stage off. The units depend on

4.3.1.1

72

the staging type. This is the destage 2-1 value and will be used

for each destaging occurrence unless Dynamic Stg is set to “Y”.

PT (primary)

The proof timer, in seconds, that will elapse before staging

4.3.1.1

5

pumps on/off.

Dynamic Stg

Select “Y” for Dynamic Stg to choose different staging and

4.3.1.1

N

(primary)

destaging values for each staging occurrence. A separate

screen will be displayed to allow for these inputs.

Sec Stg Mthd

Secondary staging method. This will be used if the sensor

4.3.1.2

Pressure

for the primary method fails. Power, Amps, and flow stag-

ing require nameplate data to be set up. See section 4.2.2.

Stg (secondary) The value at which pumps will stage on. The units depend on

4.3.1.2

System

the staging type. This is the stage 1-2 value and will be used for

Pressure – 10

each staging occurrence unless Dynamic Stg is set to “Y”.

Dstg

The value at which pumps will stage off. The units depend on

4.3.1.2

System

(secondary)

the staging type. This is the destage 2-1 value and will be used

Pressure – 3

for each destaging occurrence unless Dynamic Stg is set to “Y”.

PT (secondary) The proof timer, in seconds, that will elapse before staging

4.3.1.2

5

pumps on/off.

Section A — Parameter List