4 the trolley – GE Industrial Solutions DC OEM Module For use with Gerapid DC Circuit Breaker User Manual

Page 9

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 4 Installing the Module

2011-04-26 S47183Ee rev.01

Design and specifications are subject to change without notice

9

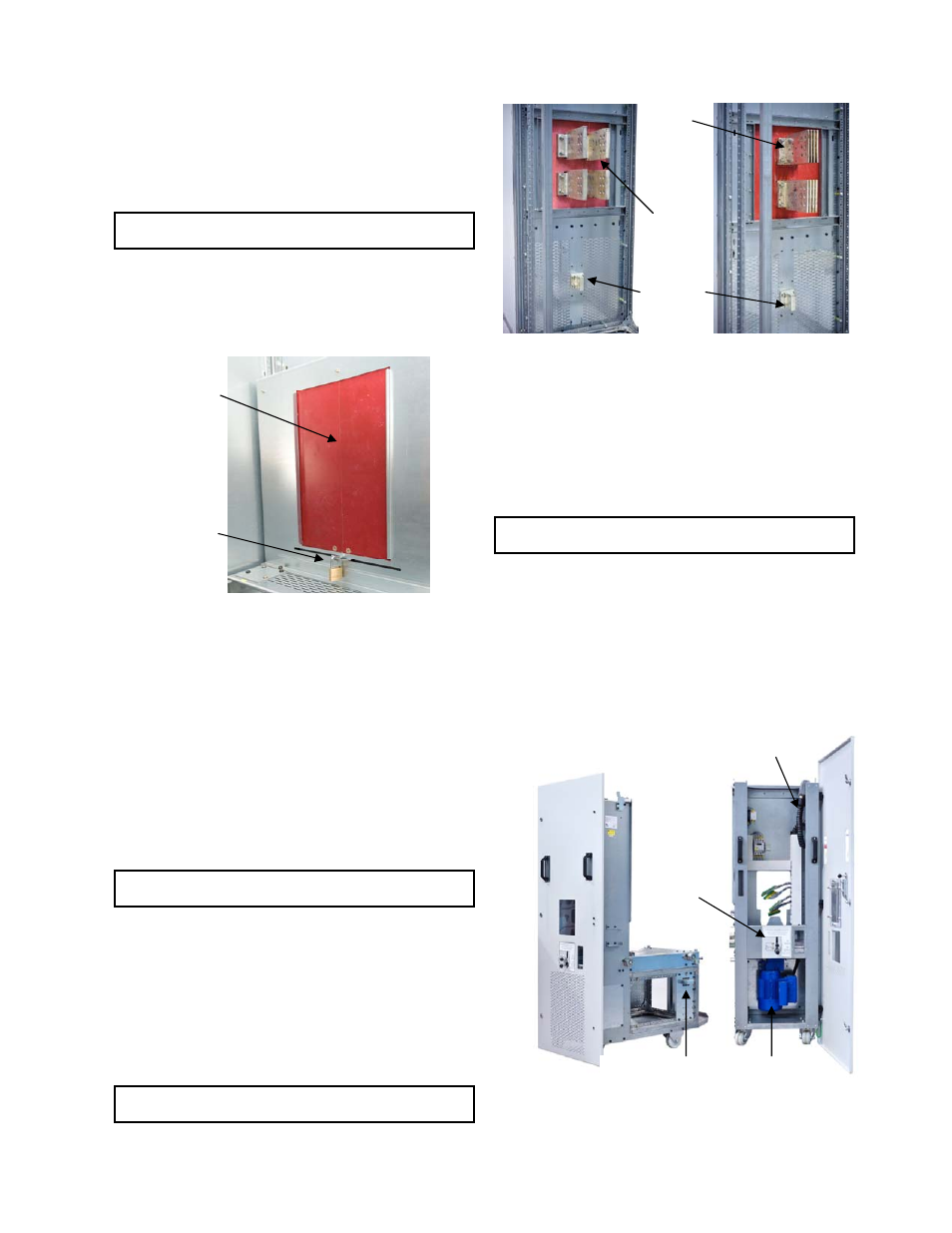

Grounded steel barriers on the top, sides, bottom, and front

enclose the breaker compartment. In the back, a flame-retardant,

track resistant, glass-filled polyester base minimizes the possibility

of fault communication between compartments or to the bus.

Breaker compartment has primary stabs for connecting the

breaker. Insulated shutters cover primary stabs. See Fig 33-2.

NOTE: See Appendix A for all dimensional drawings of the

breaker Compartment.

Primary disconnect shutters are provided as standard feature to

provide protection against contact with the energized stationary

primary stabs when the trolley is removed from its compartment.

The shutters are constructed from fiberglass reinforced thermoset

polyester. A padlock can lock the shutters in the closed position.

See Fig. 33-3.

Fig. 33-3 Safety padlock on the shutters

Every module is equipped with rejection Interlock that must be

properly configured by the OEM. This interlock allows

configurations for all current ratings. It is placed on both sides of

the breaker compartment. See Fig. 33-2.

Cable Compartment

The primary stabs extend into the cable compartment and are

suitable for connection with ANSI type busbars. Fig 33-4 shows

primary terminals for 4000A and 6000 A rated modules. Ground

bus connection in the cable compartment is the same on all

module types. Cable compartment is provided without side

covers. See Fig. 33-1. Painted and pre-punched side covers can

be ordered as separate accessories.

NOTE: See Appendix A for all dimensional drawings of the

primary terminals and cable compartment.

Module is also equipped with trolley-operated contacts that are

activated in CONNECTED and TEST position as well as with some

other limit switches that are used for internal interlocks.

Control Compartment

The secondary control plug located in the breaker compartment

is prewired, with a 3ft tagged wire harness brought into the

controls compartment for User’s connections. The matching

secondary disconnect plug is mounted on the trolley.

NOTE: See Appendix A for all dimensional drawings of the

Control Compartment.

Fig. 33-4 Rear views of 4000A and 6000A Modules

3-4 The Trolley

The module is designed to be used with Gerapid high-speed

circuit breaker installed on the withdrawable trolley. The trolley

can be ordered in two different versions, with manual racking or

with motor operated remote racking system.

Remote racking trolley equipped with motor drive can also be

operated manually by the crank handle.

NOTE: The crank handle is an accessory and has to be

ordered separately.

Trolley structure is compatible with all the modules and all

Gerapid circuit breakers listed in Section 3-5. The OEM must

correctly configure the rejection Interlock on the trolley and in the

module for the specific rating of breaker being installed.

All breaker controls, control power supply and auxiliary contacts

are extended to the control compartment via the secondary

disconnect and harness. Negative and positive interlocks are

operated from access console at the front of the trolley. The

access opening for the manual crank handle is there as well.

Fig. 34-1 Trolley features (motorized racking shown)

4000A

Terminals

Shutters

Padlock

Secondary Disconnect Plug

Motordrive

Rejection Interlock

Access

Console

6000A

Terminals

Ground

Bus

Connection