GE Industrial Solutions DC OEM Module For use with Gerapid DC Circuit Breaker User Manual

Page 45

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX H Field Test Procedure.

2011-04-26 S47183Ee rev.01

Design and specifications are subject to change without notice

45

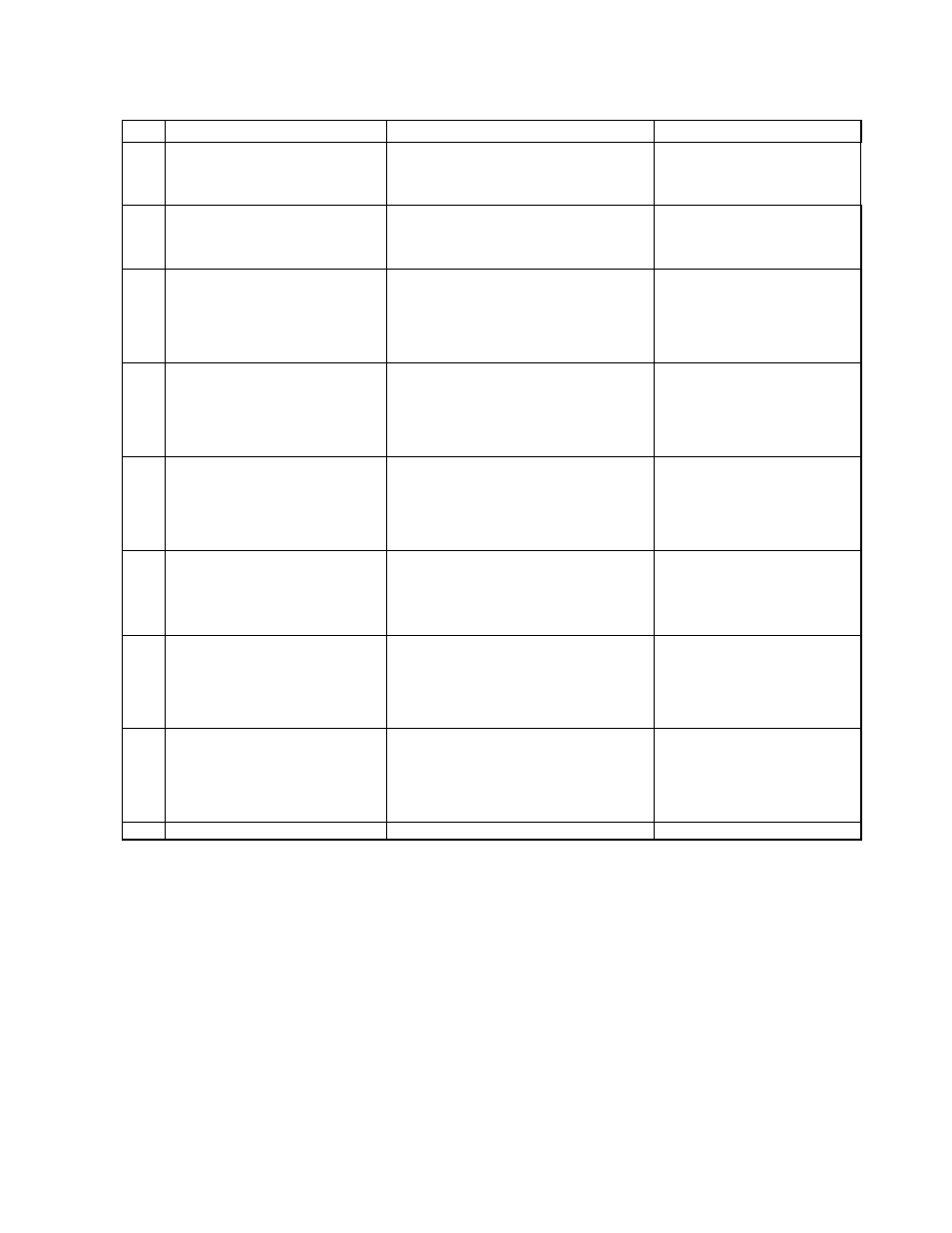

Table H-4 DC Module w/o Remote Racking - Field Test Procedure

Step Starting Point

Check Points

Pass Criteria

1.1

Trolley is in WITHDRAWN position.

Breaker is OPEN.

Insert Crank Handle (b) into Access Slot

(c).

a. Try to rack-in the trolley to CONNECTED

position.

a. The trolley must not move,

while Secondary Plug (g) is

disconnected

1.2

Trolley is in DISCONNECTED position.

Breaker is OPEN.

Insert Crank Handle (b) into Access Slot

(c). Connect Secondary Plug (g).

a. Try to CLOSE the breaker.

a. The breaker must not CLOSE,

while Crank Handle (b) is

inserted.

1.3

Trolley is in TEST position.

Breaker is OPEN.

Remove Crank Handle (b) from the slot

(c).

a. CLOSE the breaker.

b. Check “Position Check” signal at this

position.

c. Try to lift up Access Lever (e).

d. Try to lift up Trip Lever (d).

a. The breaker must CLOSE.

b. “Positions Check” signal must

be active.

c. The Access Lever must not

move, while breaker is CLOSED.

d. The breaker must OPEN.

1.4

Trolley is in TEST position.

Breaker is OPEN.

Insert Crank Handle (b) into Access Slot

(c).

a. Rack-in the trolley to a position between

TEST and CONNECTED.

b. Remove Crank Handle.

c. CLOSE the breaker.

d. Rack-in the trolley to CONNECTED

position.

c. The breaker must not CLOSE, if

it is not in TEST or CONNECTED

position.

1.5

Trolley is in CONNECTED position.

Breaker is OPEN.

a. Remove Crank Handle.

b. CLOSE the breaker.

c. Try to lift up Access Lever (e).

d. Try to lift up Trip Lever (d).

e. Check “Position Check” signal at this

position.

b. The Access Lever must not

open, while breaker is CLOSED.

c. The breaker must OPEN.

d. “Positions Check” signal must

be active.

1.6

Trolley is in CONNECTED position.

Breaker is OPEN.

Insert Crank Handle (b) into Access Slot

(c).

a. Rack-out the trolley into a position

between CONNECTED and TEST.

b. Remove Crank Handle.

d. CLOSE the breaker.

e. Rack-out the trolley into TEST position

c. The breaker must not CLOSE, if

it is not in TEST or CONNECTED

position.

1.7

Trolley is in TEST position.

Breaker is OPEN.

Remove Crank Handle (b) from slot (c).

a. CLOSE the breaker.

b. Try to lift up Access Lever (e).

c. Try to lift up Trip Lever (d).

d. Check “Position Check” signal at this

position.

b. The Access Lever must not

open, while breaker is CLOSED.

c. The breaker must OPEN.

d. “Positions Check” signal must

be active.

1.8

Trolley is in TEST position.

Breaker is OPEN.

a. Try to manually pull trolley out of the

module.

b. Disconnect Secondary Plug (g).

c. Try to manually pull trolley out of the

module.

a. The trolley must not move out

of the module, while Secondary

Plug is connected.

c. The trolley must move out of

the module.

1.9

END OF PROCEDURE