Installing the module, 2 module configuration and assembly – GE Industrial Solutions DC OEM Module For use with Gerapid DC Circuit Breaker User Manual

Page 11

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 4 Installing the Module

2011-04-26 S47183Ee rev.01

Design and specifications are subject to change without notice

11

Installing the Module

4-1 General Notes

This chapter contains instructions for installing the GE DC OEM

Module.

CAUTION: Personnel installing this equipment must be

thoroughly familiar with this instruction manual and all articles

of the National Electrical Code applicable to the installation of

this equipment. In addition, all drawings, both mechanical

installation and electrical, must be understood and strictly

followed to prevent damage to the module.

Environmental Requirements

The module as provided is designed for indoor installations only

and should be placed in an indoor area where clean, dry air is free

to circulate around and above it. Since air is taken into the

equipment at the bottom of each section and exhausted at the

top, a location with good airflow must be provided for efficient

operation.

A minimum of 30 inches of clear space above the equipment is

recommended. In order to properly withdraw the trolley there

should be at least 7 foot of space in the front of the module.

NOTE: See Appendix C for sketches concerning layout.

Foundation Requirements

The foundation requirements detailed in this chapter should be

strictly adhered to.

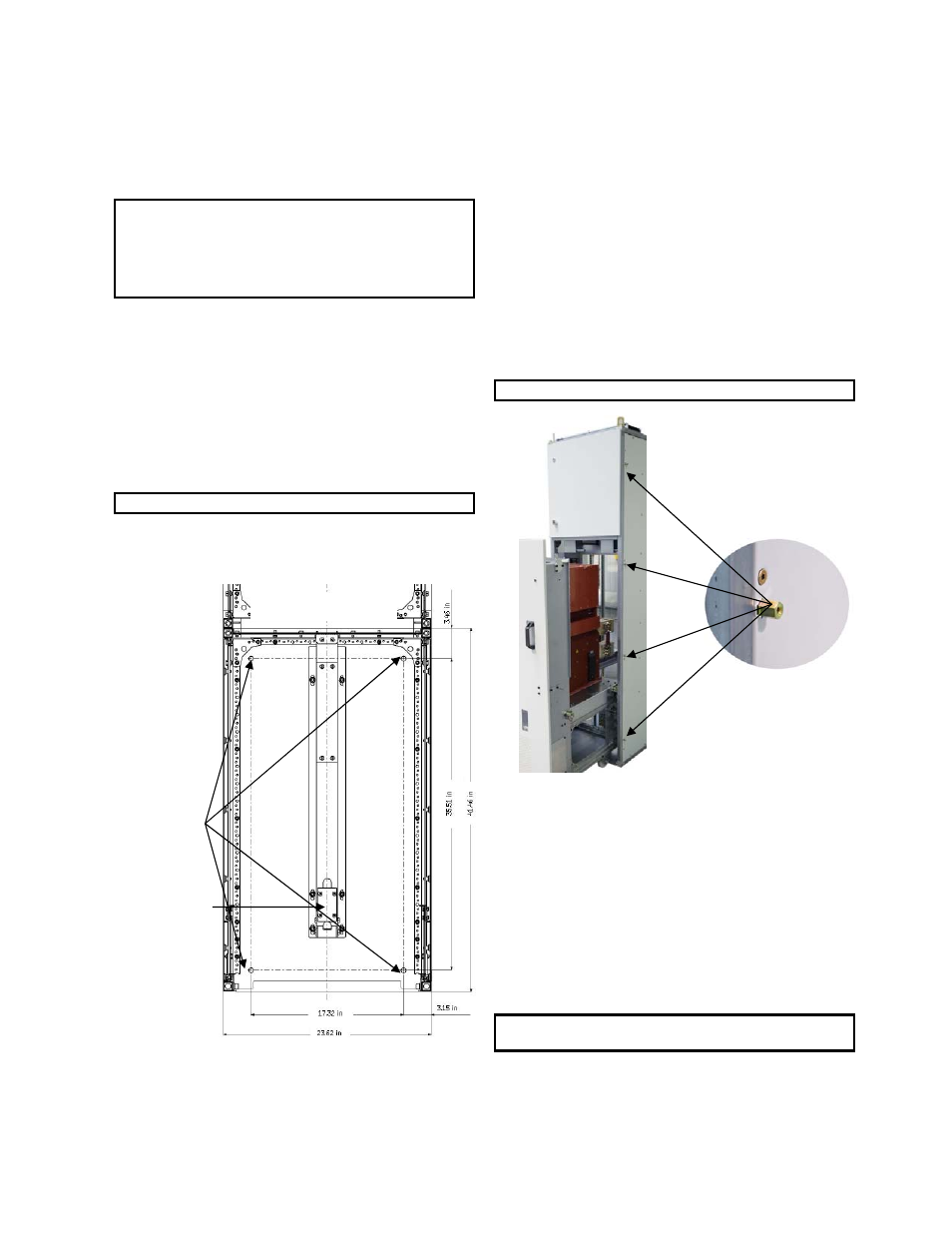

Fig.41-1 Module anchor bolt hole locations

The foundation must be strong enough to prevent sagging due to

the weight of the completed switchgear structure and to

withstand the impact loading caused by the opening of the

breakers under fault conditions. The impact loading is

approximately 1-1/2 times the static load.

The foundation must be flat and level in all planes with maximum

deviation of 0.8 inch at the length of 3 foot. The module should be

anchored to the floor through holes shown on Fig. 41-1 using

7/16” or metric M12 grade 5 steel bolts.

4-2 Module Configuration and Assembly

Multiple Modules Side by Side Assembly

Modules can be connected together to form switchgear lineups.

To bolt two modules together, edge trim strips must be removed.

Special connection spacers must be used and are inserted into 12

hex shaped cut outs visible in the sidewalls. Fig. 42-1 shows the

location of the front 4 connection spacer openings. Location of all

openings and installation tips are shown in Appendix G.

A Module Coupling Kit can be ordered under Cat. No.: 289169.

Each kit consists of 12 Connection spacers, bolts and washers

necessary to connect two adjacent modules.

NOTE: See Appendix D for connection drawings.

Fig. 42-1 Location of front module connection spacers

Module Preparation

Every module is suitable for operating either with manually or

motor operated trolley. Depending on the type of trolley being

utilized, a locking plate in the module may need to be removed:

If motor operated trolley is going to be used with the

Module, remove the locking plate.

If manually operated trolley is going to be used with the

module, keep the locking plate in place

See Fig. 41-1 and Fig. 42-2 to locate locking plate.

NOTE: Look for the yellow warning label placed on the

module’s floor to find bottom guide rail and the plate.

Connection Spacers

12 per side-by-side.

Top View on the floor.

Anchor Points

Use M12 or

7/16” grade 5

bolts.

Locking Plate