3 storage – GE Industrial Solutions DC OEM Module For use with Gerapid DC Circuit Breaker User Manual

Page 7

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 2 Receiving, handling and storage

2011-04-26 S47183Ee rev.01

Design and specifications are subject to change without notice

7

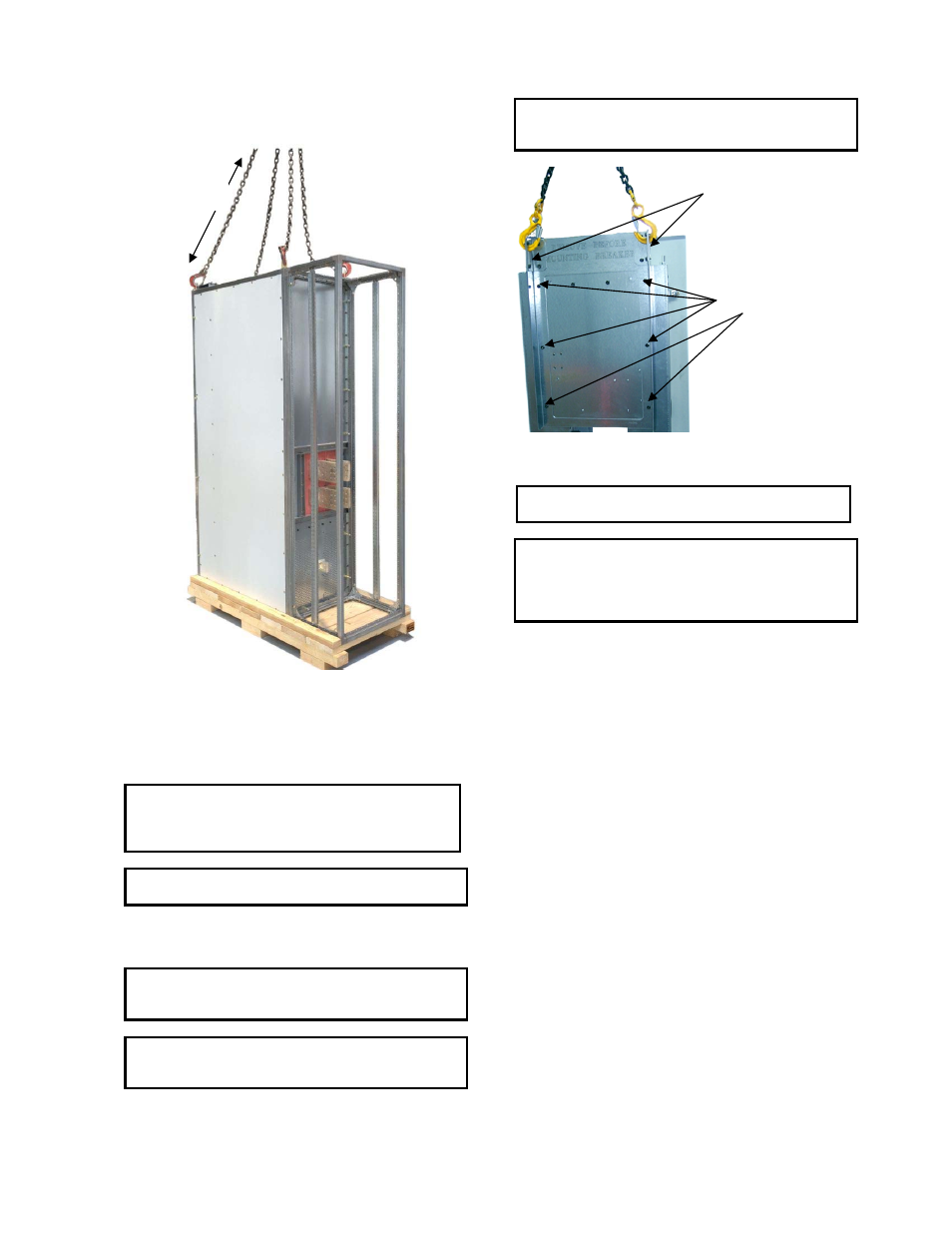

Removable lifting plates are provided on the top of each

module, as standard equipment. Using a crane or overhead

hoist, carefully lift the module from the palette using the four

lifting plates. (See Fig. 22-1)

Fig. 22-1 Overhead lifting of the module

To preserve the external appearance of the equipment, it is

suggested that the lifting plates be left in place. Utilize four

equal length cables or slings, each with a minimum load rating

of twice the weight of the Module package. See section 2.1.

NOTE: The angle between the cables and the top of the

equipment must be at least 45 degrees. This requires the

use of chains/slings at least 4 ft long. If this is not possible,

spreader bars must be used.

NOTE: Do not move, lift or handle the module with a trolley

installed.

Take up the slack in the lifting device very carefully and

manually stabilize the module to prevent it from rotating.

WARNING: Do not stand under the module while it is being

moved. Serious injury may occur if the cables or lifting

device fail.

CAUTION: Gently lower the module onto the level site

location. If the module is roughly handled or jarred, it is

possible to damage or misalign internal components.

Trolley handling and unpacking

The trolley, in its original package, should be transported using

forklift only. To unpack the trolley, remove the top cover first,

and then remove sidewalls and all inner supports. To lift the

trolley, use special lifting frame available. See Fig. 22-2.

NOTE: After transportation, but before installing of the

breaker, loosen six attachment screws and remove lifting

frame from the trolley. Replace and tighten these screws!

Fig. 22-2 Lifting of the trolley

CAUTION: Never use forklift to transport unpacked trolley,

as it is not bolted or fixed to the shipping palette

NOTE: Do not lift or transport the trolley, using forklift.

Never lift the trolley with a breaker mounted. Never roll the

trolley on the floor with a breaker set in place, unless the

breaker is properly bolted to the trolley and arc chutes

properly secured to the breaker (if installed).

2-3 Storage

Circuit Breakers

Open shipping cartons and thoroughly inspect shipping

materials for damage. If shipping plastic is in satisfactory

condition, leave the breakers in their shipping cartons for

storage. Do not remove the circuit breaker shipping material

(shrink wrap) at this time.

Store the circuit breakers in a clean, dry location in an upright

position. If shipping plastic is damaged, a plastic or canvas-

type cover should be provided to reduce the possibility of

damage or contamination to the breakers due to dust and

water. For details concerning Gerapid breakers handling

consult the breaker’s User Guide, S47183De.

Modules and Trolleys

Remove protective covering. Check thoroughly for damage.

Store in a clean, dry, rodent-free location with moderate

temperature and provide protective coverings to prevent dirt,

water, or other foreign substances from entering the

equipment.

If dampness or condensation may be encountered in the

storage location, heaters must be placed inside the module

breaker compartment (module must be without trolley) and in

the front of the trolley with trolley door open to prevent

condensation. Approximately 250 watts of heat in each

section is required. Incandescent lamps can be used and

located in the bottom of the breaker compartment and

supported so the bulbs will not touch adjacent materials.

Min. 4 ft

Lifting slots.

Fixing screws.