GE Industrial Solutions DC OEM Module For use with Gerapid DC Circuit Breaker User Manual

Page 20

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 7 Operating the Module

20

Design and specifications are subject to change without notice

S47183Ee rev.01 2011-04-26

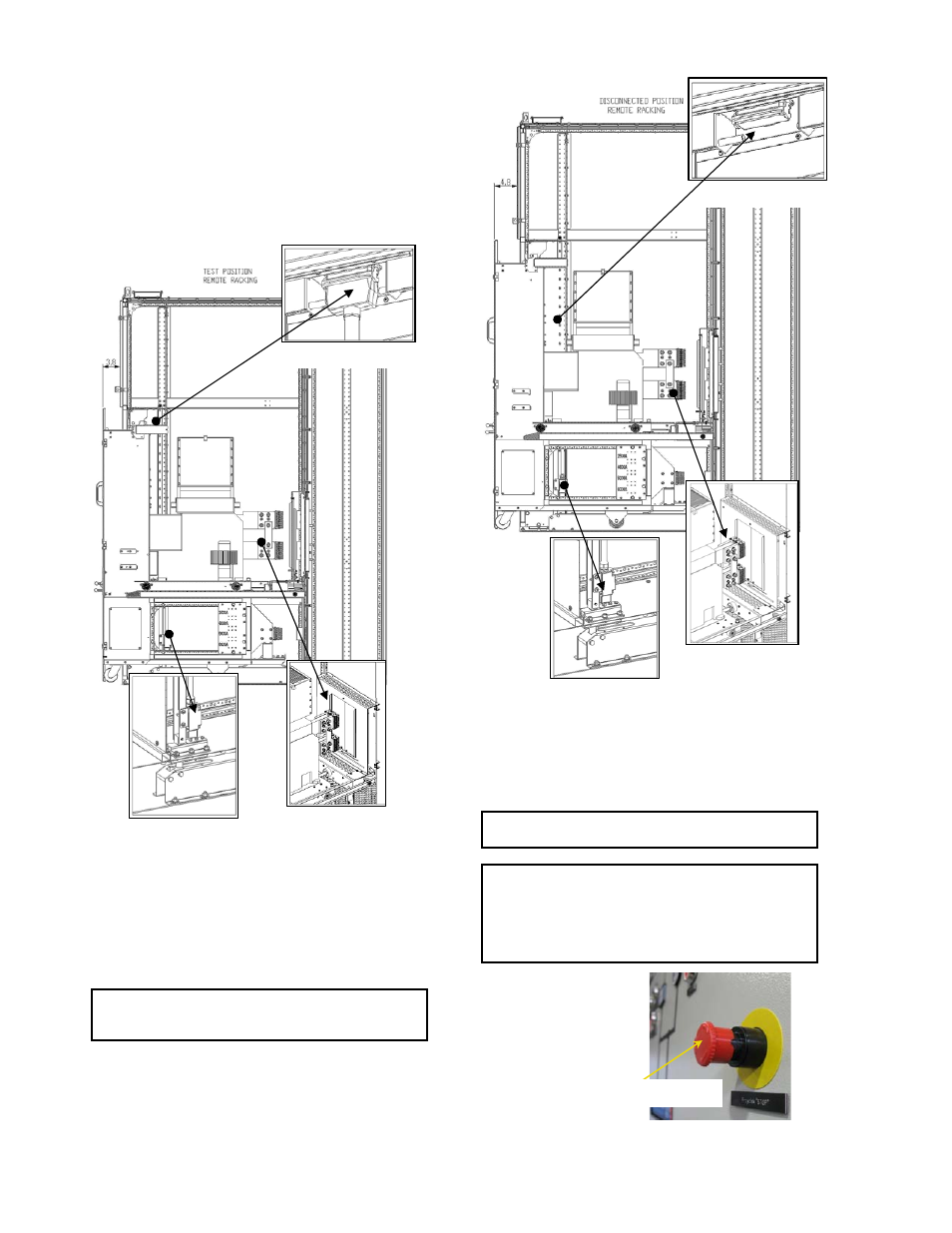

1. CONNECTED position – Primary Disconnects and

Secondary Disconnect in full contact, breaker ready for normal

operation. Position Interlock, see Fig. 73-1, keeps the trolley in

this position.

2. TEST position - Primary Disconnect open and separated by

a safe distance with shutters closed. The Secondary

Disconnect is in full contact. The Trolley is withdrawn ~4 inches

and locked by Position Interlock. See Fig. 72-3.

Fig. 73-2 TEST position for remote racking trolley

3. DISCONNECTED position - Primary Disconnects open and

separated by a safe distance with shutters closed. Secondary

Disconnect is open. Trolley is withdrawn ~5 inches. See Fig. 72-

3.

4. WITHDRAWN position – Trolley outside of the module.

NOTE: Remote racking-operations require control voltage

and control commands to be provided. See Appendix E for

electrical circuit drawings.

Fig. 73-3 DISCONNECTED position for remote racking

trolley.

Remote Rack–In Procedure.

NOTE: Crank Handle is necessary for completing racking

operations. Crank Handle has to be ordered separately.

WARNING: EMERGENCY RACKING STOP circuit (Y58 Y59)

must be wired to a pushbutton (furnished by OEM). It is

recommended the STOP PB be installed on the control

compartment door. See example Fig. 73-4.

Use this pushbutton for immediate interruption of racking

operation and stop the trolley regardless of its position.

Fig. 73-4 EMERGENCY STOP pushbutton (by OEM)

Secondary Disconnect

Primary Disconnects

Position Interlock

Secondary Disconnect

Primary Disconnects

Position Interlock

EMERGENCY RACKING STOP