GE Industrial Solutions DC OEM Module For use with Gerapid DC Circuit Breaker User Manual

Page 12

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 4 Installing the Module

12

Design and specifications are subject to change without notice

S47183Ee rev.01 2011-04-26

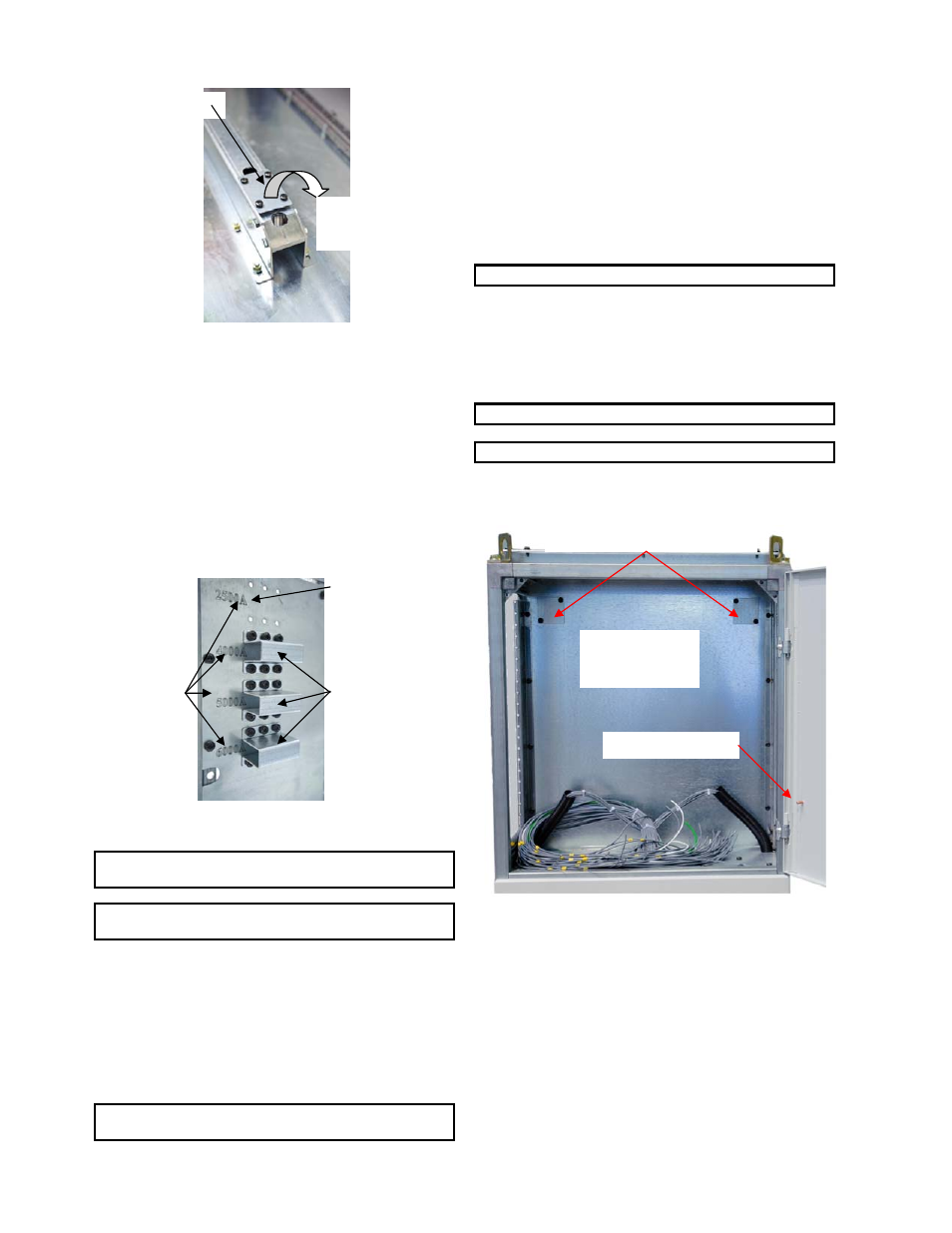

Fig. 42-2 Locking Plate

Module Rejection Interlock

OEM must configure the rejection interlock in the module, before

its usage. Four different configurations are possible: 2500A,

4000A, 5000A or 6000A. In the module, rejection markers must be

screwed in place aligned with all current ratings except the one

that module is dedicated to. This should be done on the right and

left side of the module.

Fig. 42-3 illustrates a correctly configured module rejection

Interlock for a 2500A rated Gerapid breaker. Rejection markers

must be fixed on both right and left sides of the breaker

compartment, aligned with ratings: 4000A, 5000A and 6000A.

Fig.42-3 Rejection interlock set up for rating of 2500A

NOTE: Always verify that the rating on rejection interlock is not

higher that the module rated current.

NOTE: Always configure rejection interlock on both sides of the

module breaker compartment.

Main Busbars Connection

Module primary terminals are silver plated copper and are

suitable to connect to copper bus bars as per IEEE Std. C37.14

Table 6. Connected bus bars should not have cross sections less

that recommend in Table 6.

Gerapid circuit breakers are not polarized. Therefore the load and

the supply line can be connected to either top or bottom terminal.

See Fig. 33-4 for primary terminals views.

NOTE: See Appendix B for primary terminals drawings and

recommend bus bar dimension.

Ground Bus Connection

Ground bus connection terminal is located at the bottom of the

module in the cable compartment. See Fig.

33-4. Circuit

connections to a ground bus are made so that it is not necessary

to open-circuit the ground bus to remove any connection made

to the ground bus. Ground connections are provided for all

removable elements to ensure that the frame and mechanism are

grounded until the primary circuit is disconnected and the

removable element is moved a safe distance.

NOTE: See Appendix B for ground terminal drawings.

Connecting Secondary Controls

Secondary disconnect plug in the module is pre-wired with the

harness going into control compartment. All wires that should be

used by OEM for completing the module and breaker control are

numbered and accessible inside the Control Compartment.

NOTE: See Appendix E for electrical schemes for connections.

NOTE: See Appendix A for control compartment dimensions.

All trolley control commands and supply connections are also

available thru the harness in the Control Compartment.

Fig.42-4 Control compartment

Device mounting on control compartment door

Control compartment’s door should be removed before making

any cutouts. To remove the door, open and remove grounding

connection. Lift the door up until the pins are free from hinges.

All auxiliary devices can be attached to the mounting plate

provided at the back of the control compartment. However it is

recommend prefabricating a separate metal sheet and installing

it in the control compartment using frame supports.

There are two cover plates that provide access to the top

mounted wire way (cable channel). Remove the covers to use

them. See Fig. 42-4.

Locking Plate

Remove for motor

operated trolley !

Installed Breaker

Rejection Markers

Rating

Markers

Components

Mounting Plate

Grounding Stud

Top mounted wire way

access covers