4 operate the breaker – GE Industrial Solutions DC OEM Module For use with Gerapid DC Circuit Breaker User Manual

Page 21

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

Chapter 7 Operating the Module

2011-04-26 S47183Ee rev.01

Design and specifications are subject to change without notice

21

1.

Trolley WITHDRAWN. Push trolley toward the module

until it stops at DISCONNECTED position.

2.

Open the trolley’s door and install Secondary

Disconnect.

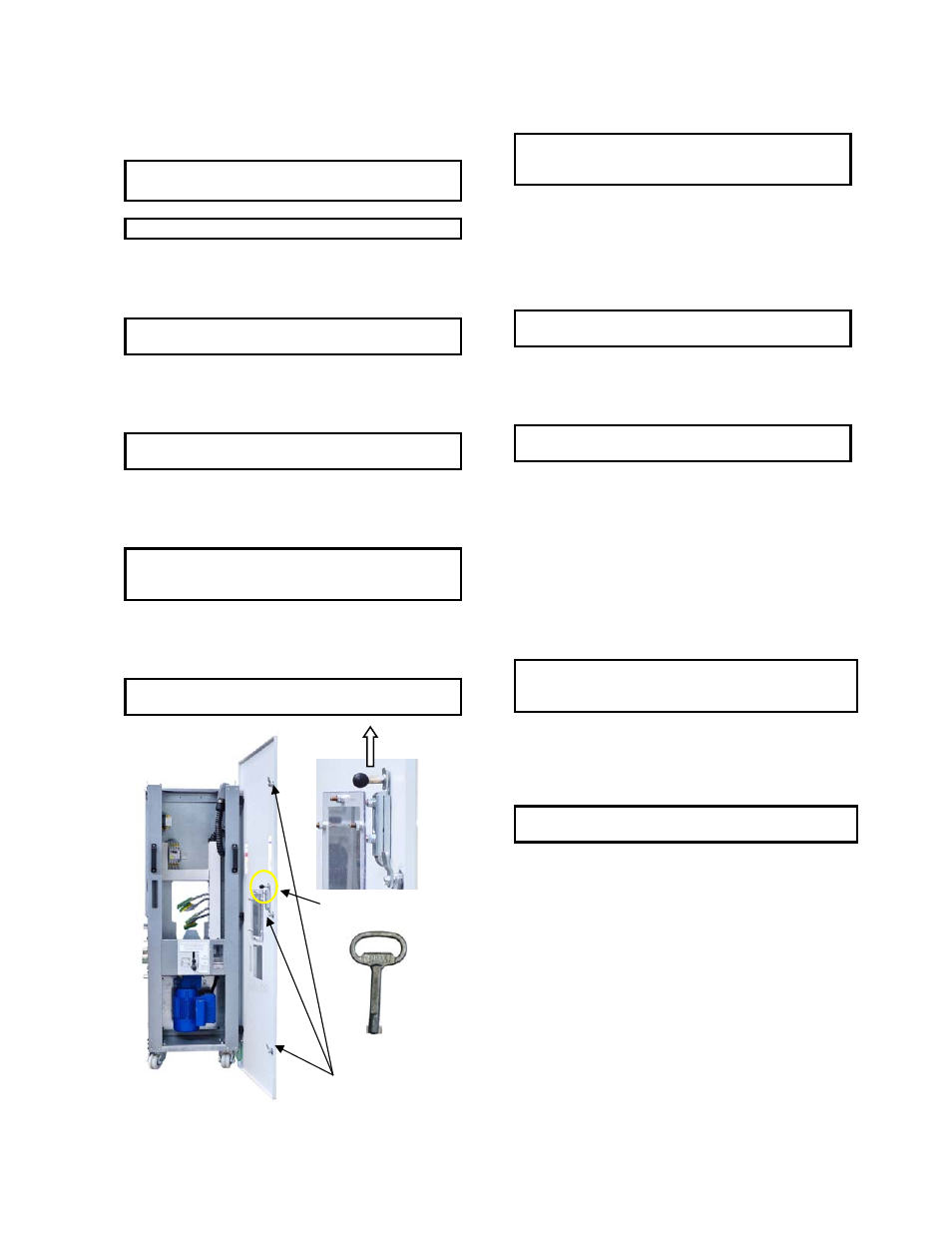

NOTE: Use the Door Key provided to open all Door Locks

and release Door Interlock. See Fig. 73-4.

NOTE: Make sure that Receptacle Snap Lock is engaged.

3.

Lift up the Access Lever (Fig. 71-4) and push the

trolley in further until racking shaft (Fig. 71-1) couples with

socket (Fig. 71-8).

NOTE: S4F contact should indicate the coupling position if

connected (Y64 Y65) to any external indication device.

4.

Insert Crank Handle into the Access Console slot,

Fig. 72-4 and rotate Crank Handle clockwise until trolley

reaches TEST position.

NOTE: TEST position is indicated by Position Indicator,

(Fig. 71-3) or by indication of switch 33-4 (Fig. 71-9).

5.

Remove Crank Handle. Push the Trip Lever down,

(Fig. 71-4), making sure that both levers of the Access

Console are in their maximum lower positions.

NOTE: If the Access Lever is not at its maximum lower

position, closing of the breaker or remote rack-in will not

be possible.

6.

Use RACK BREAKER-IN command (Y60 Y61) to start

motor for rack in operation. Trolley will stop at

CONNECTED position.

WARNING: Use EMERGENCY STOP pushbutton in case of

emergency situation. See Fig.73-4.

Fig. 73-4 Door locks

Manual Rack-Out Procedure.

NOTE: Crank Handle is necessary for completing of

racking operations. Crank Handle has to be ordered

separately.

1. Trolley CONNECTED. Open the breaker either using

OPEN command or pulling up the Trip Lever (Fig. 71-

4).

2. Use RACK BREAKER-OUT command (Y62 Y63) to start

motor for rack out operation. Trolley will stop at TEST

position.

NOTE: TEST position is indicated by Position Indicator,

(Fig. 71-3) or by indication of switch 33-4 (Fig. 71-9).

3. Open the trolley’s door and disconnect the

Secondary Disconnect. Hang it on the frame to the

right (Fig. 71-7).

NOTE: Use the Door Key to open all Door Locks and

release Door Interlock. See Fig. 73-4.

4. Lift up the Access Lever (Fig. 71-4) and insert Crank

Handle. Rotate Crank Handle counterclockwise until

trolley stops. Now the trolley is in the DISCONNECTED

position.

5. Remove Crank Handle. Lift up the Access Lever

(Fig. 71-4) and pull the trolley out from the module.

7.4 Operate the breaker.

Gerapid circuit breakers can be operated electrically and

manually.

NOTE: Manual CLOSE operation at the breaker is possible

only at WITHDRAWN position of the trolley. Manual closing

should only be performed for maintenance.

Manual OPEN operation at CONNECTED or TEST positions is

possible by means of Trip Lever. For maintenance purposes

breaker can be operated by means of dedicated hand lever at

WITHDRAWN position.

NOTE: See User Manual S47183De for breaker operation

details and accessories.

All electric control commands and signals are wired thru

available harness (Y01 Y54). See Appendix E for details of

available commands and signals.

Lift to release

Door Locks

Door Key

Door Interlock