Appendix h – field test procedure, Connecting control commands for testing – GE Industrial Solutions DC OEM Module For use with Gerapid DC Circuit Breaker User Manual

Page 43

DC OEM MODULE FOR USE WITH GERAPID CIRCUIT BREAKERS

APPENDIX H Field Test Procedure.

2011-04-26 S47183Ee rev.01

Design and specifications are subject to change without notice

43

APPENDIX H – Field Test Procedure

This Appendix describes full recommended procedure for Field Testing of DC OEM Module equipped with Gerapid DC Circuit Breaker.

The description consists of four chapters:

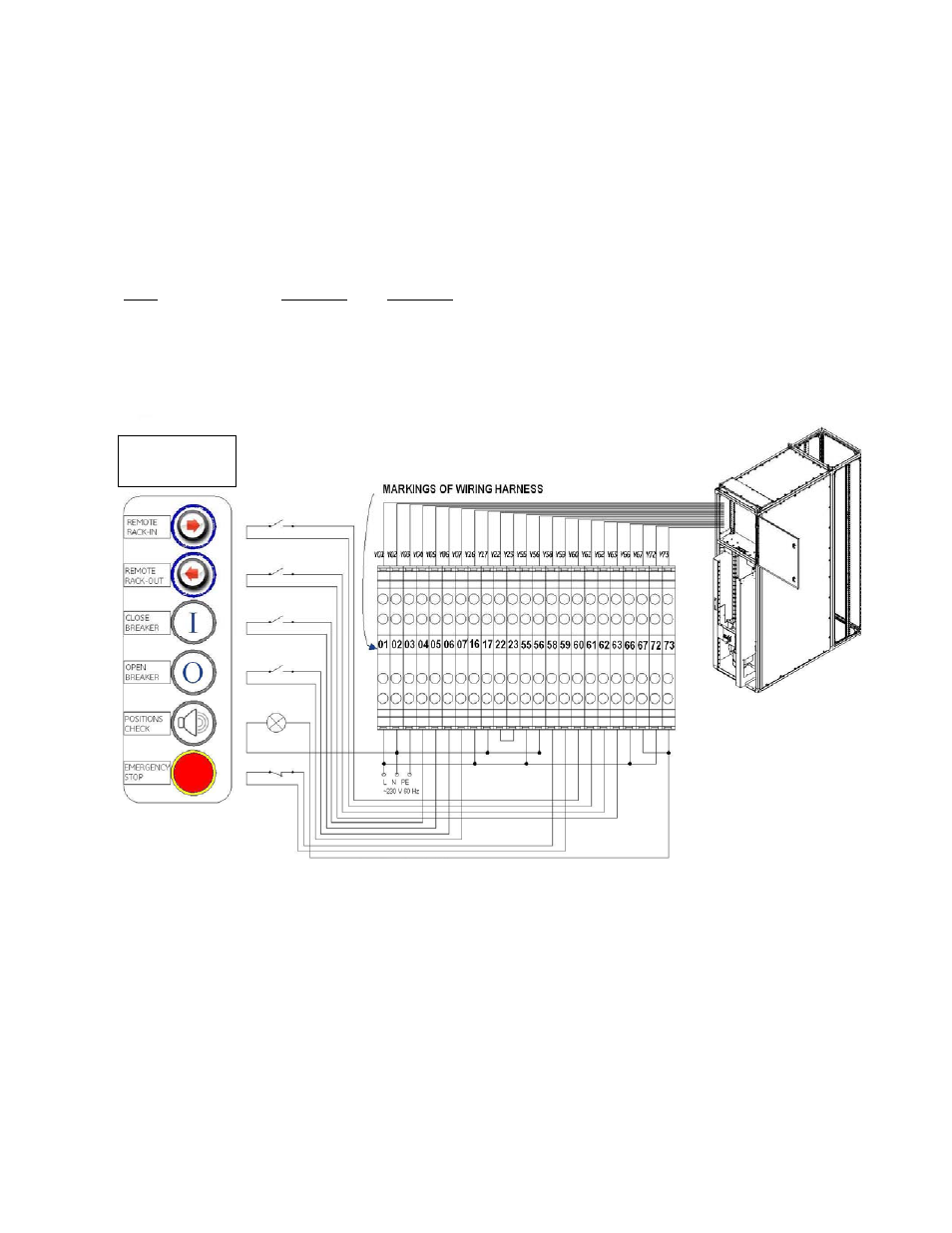

Connecting control commands to the module. See Fig. H-1

Testing the module with Remote Racking. See Table H-3.

Testing the module with Manual Racking. See Table H-4.

High potential test (optional). See Table H-6.

Connecting control commands for testing

Following control commands are available for OEM wiring:

Name

Wire Points

Description

RACK BREAKER-IN

(Y60-Y61)

Moves trolley from TEST to CONNECTED position.

RACK BREAKER-OUT

(Y62-Y63)

Moves trolley from CONNECTED to TEST position.

GERAPID SOLENOID CLOSE– (Y04-Y05)

Closes Gerapid breaker, possible only in TEST or CONNECTED positions.

GERAPID OPEN

(Y06-Y07)

Opens Gerapid breaker, possible only in TEST or CONNECTED positions.

POSITIONS CHECK

(Y67/Y73)

Signals when trolley reaches TEST or CONNECTED position.

EMERGENCY RACKING STOP (Y58-Y59)

Immediately stops the trolley regardless of position.

Fig. H-1 Wiring diagram for connection of control functions for the module.

Typical external

controls, furnished

by OEM.