Service bulletin supplement, Measure and adjust input shaft end play – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 73

Service Bulletin Supplement.

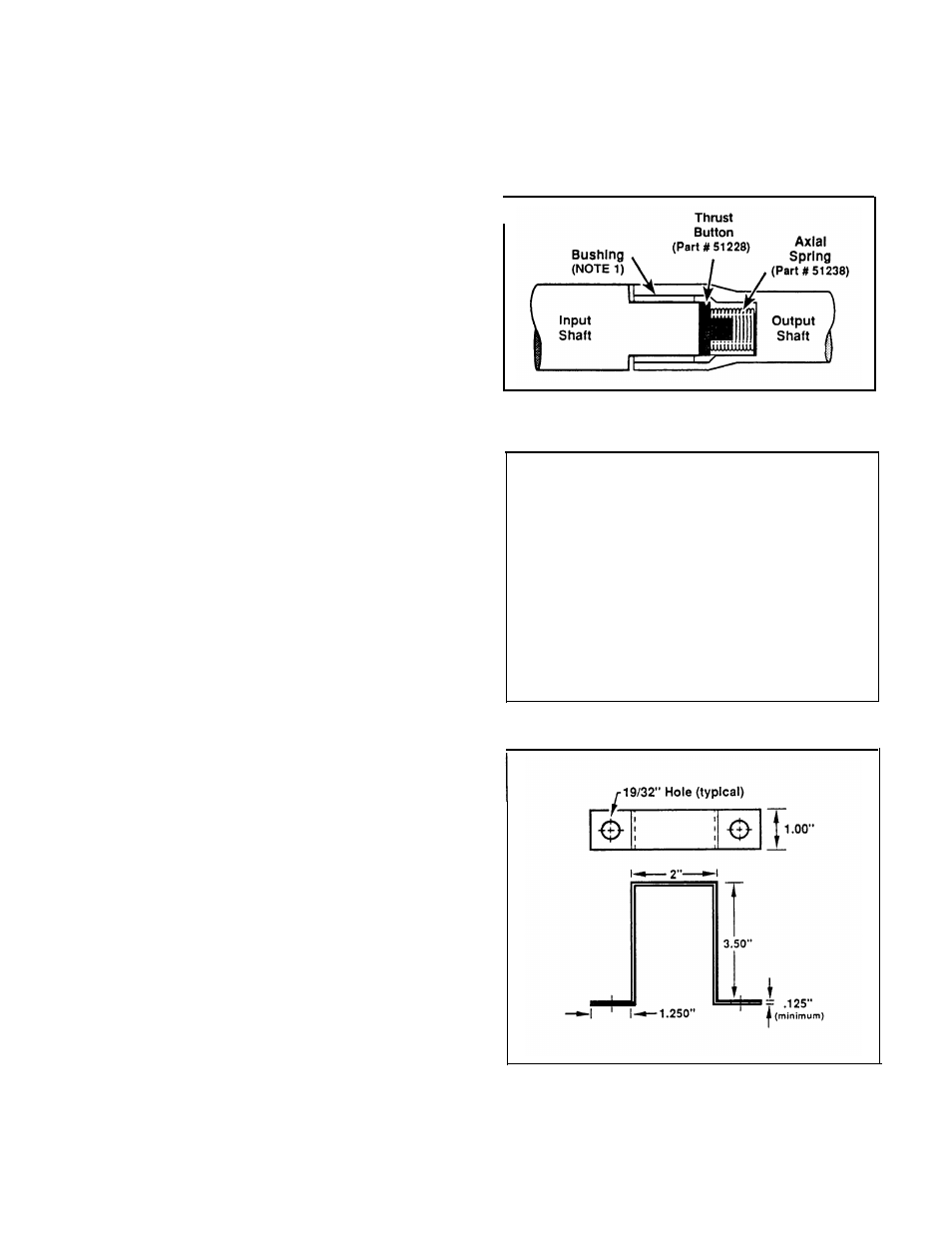

Input Shaft End Play for Axle Models equipped with an Input Shaft Axial Spring

and Thrust Button.

In September 1988, Spicer added an Axial

Spring and Thrust Button between the input

and output shafts. The addition of these parts

reduces shaft end play movement by loading

the shafts axially in the direction of the yoke.

End play tolerances are the same for axles

with or without the new Spring and Thrust

Button. However, end play measurement

procedure is different as described below.

Measure and Adjust Input Shaft End

Play.

NOTE:

The addition of the Spring and

Thrust Button between the input and output

shafts necessitates the fabrication of a “U”

bracket to assist in measuring the shaft end

play. Proceed as follows:

1.

Fabricate a “U” bracket from 1“ flat stock

(minimum thickness 0.125”) as specified in

the illustration.

2. If axle is disassembled,

build up a 0.045”

(0.024 mm) thick shim pack and place shim

pack and bearing cover on power divider

cover. Then proceed with Step 3.

If axle is assembled,

remove input shaft

nut, flat washer and yoke. (NOTE: Axles

built with metric threaded nuts do not use

flat washers.) Then proceed with Step 3.

I

Location of Axial Spring and Thrust Button.

Input Shaft End Play Chart

New or Rebuild with new

NOTE:

Because of manufac-

parts 0.003” to 0.007”

turing variations in individual

parts, correctly adjusted end

Rebuild with reused parts play could vary 0.010,” after

0.013" to 0.017"

the unit is rotated.

Acceptable End Play Tolerances

when measuring as a

regular maintenance procedure with axle in truck.

Up to 0.060”

with over

NOTE:

If end play exceeds

100,000 miles or 1 year

limits, disassemble power

service off-road.

divider and replace worn

parts.

Up to 0.040”

with less than

100,000 miles or 1 year

service on-road.

“U” Bracket Specifications.

NOTE 1:

Bushing no longer used in current production axles, see pages 37 & 38.

74