Axle shift components. i, Model lockout, Standard” "non-current” model lockout overhaul – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 67: Retrofit “non-current” to “current

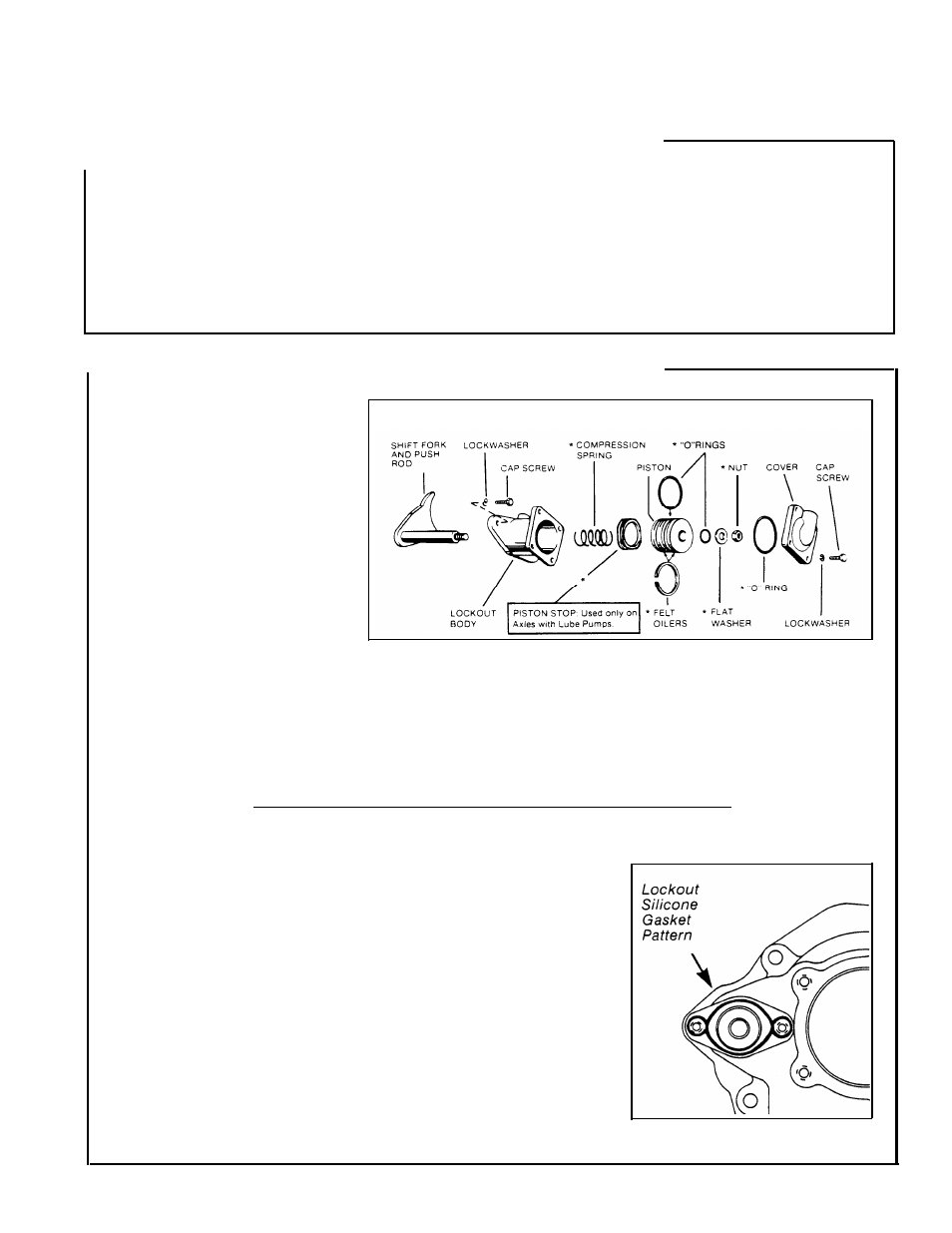

Axle Shift Components.

I

Retrofit “Non-Current” to “Current”

Model Lockout

The “current” model (only as an

assembly) is interchangeable with

the “non-current” lockout. The

original shift fork and push rod can

be used for either model lockout

and need not be replaced.

Retrofit Kits are available to convert

the “non-current” model to the

“current” lockout. Parts (except the

shift fork), included in these kits are

2.

Assemble and install “current”

shown in the illustration on the

lockout following instructions on

preceding page. For additional

preceding page.

information, refer to Spicer Parts

NOTE:

Do not use mounting screws

Books (see inside back cover).

from “non-current” model. They

are too long to use with the new

1.

Disassemble and remove

“current” model.

“non-current” lockout. Refer to

instructions below.

“Standard” "Non-Current” Model Lockout Overhaul

Service Parts Availability.

The

“non-current” lockout assembly,

body, piston and body cover are

no longer available. If any of these

items are not serviceable, replace

lockout with the new “current”

model per instructions above. For

other parts, a Service Parts Kit

(see illustration) is available to

service the “non-current” lockout.

Disassemble and Remove Lockout

1.

Remove cap screws and

lockwashers fastening cover to the

body. Remove cover and “O’’ ring.

2.

Remove nut, flat washer and

“O’’ ring from push rod.

“Standard” “Non-Current” Model Lockout

*Asterisk Identifies parts included in Service Kit 277207

NOTE: Axles with Lube Pumps:

These axle models are equipped with a

piston stop located at base of piston.

reinstalled in reassembly.

3.

Remove body cap screws and

lockwashers, then remove body

and piston as an assembly. Remove

“O’’ ring and felt oilers from the

piston.

It is important that this stop be

NOTE:

The shift fork and push rod

cannot be removed with power

divider cover installed (see Power

Divider instructions).

Assemble and Install Lockout

With shift fork and sliding clutch

installed in power divider cover,

assemble and install lockout as

follows.

1.

Apply silicone gasket compound

to mounting surface on power

divider cover. See illustration.

2.

Install lockout body. Secure with

cap screws and lockwashers.

Torque cap screws to 48-56 Ibs.-ft.

(65-76 N•m).

NOTE:

Before installation, soak

piston felt oilers in SAE 30 engine

oil and lubricate “O’’ rings with a

high-viscosity silicone oil or barium

grease “O’’ ring lubricant.

3.

Install felt oilers and large

“O” ring on piston.

Axles with Lube Pump.

Before

installing piston, place piston stop

at base of lockout body.

4.

Install compression spring over

shift fork push rod. Install piston in

body and secure with “O” ring, flat

washer and nut. Torque nut to

20-26 Ibs.-ft. (27-35 N•m).

5. install “O’’ ring in lockout body

cover. Install cover and secure with

cap screws and lockwashers.

Torque cap screws to 96-108

LBS.-IN (10-12 N•m).

68