Differential carrier, Adjust input shaft end play, Measure and adjust end play – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 19

I

Differential Carrier

Adjustments help provide optimum axle life and performance by correctly

positioning bearings and gears under load.

The tandem axles covered in

this

manual require the following adjustments:

Bearing Preload:

This adjustment is

Ring Gear Tooth Contact:

This adjust-

Input Shaft End Play (Forward Axles):

performed for both pinion and differ-

ent positions ring gear and pinion

This adjustment controls gear mesh

ential bearings. It maintains proper

for best contact under load. Correct

in the inter-axle differential. Proper

gear alignment by creating correct

adjustment distributes torque evenly

adjustment helps maximize life of all

bearing cone and cup relationship for

over gear

teeth and helps maximize

power divider parts.

free rotation under load. The pinion

gear set life.

pilot bearing does not require

a pre-

load adjustment.

Adjust Input Shaft End Play

Specifications:

Input shaft end play requirements will vary with operat-

ing conditions, mileage and rebuild procedures. These variations are

shown in the following chart.

Input

Shaft End Play Chart

New or Rebuild with new parts

NOTE:

Because of manufacturing

0.003" to 0.007"

variations in individual parts,

correctly adjusted end play could

Rebuild with reused parts

vary 0.010", after the unit is

0.013" to 0.017"

rotated.

Acceptable End Play Tolerances when measuring as

a regular maintenance procedure with axle in truck.

Up to 0.060" with over 100,000

NOTE:

If end play exceeds limits,

miles or 1 year service off-road.

disassemble power divider and

replace worn parts.

Up to 0.040" with less than 100,000

miles or 1 year service on-road.

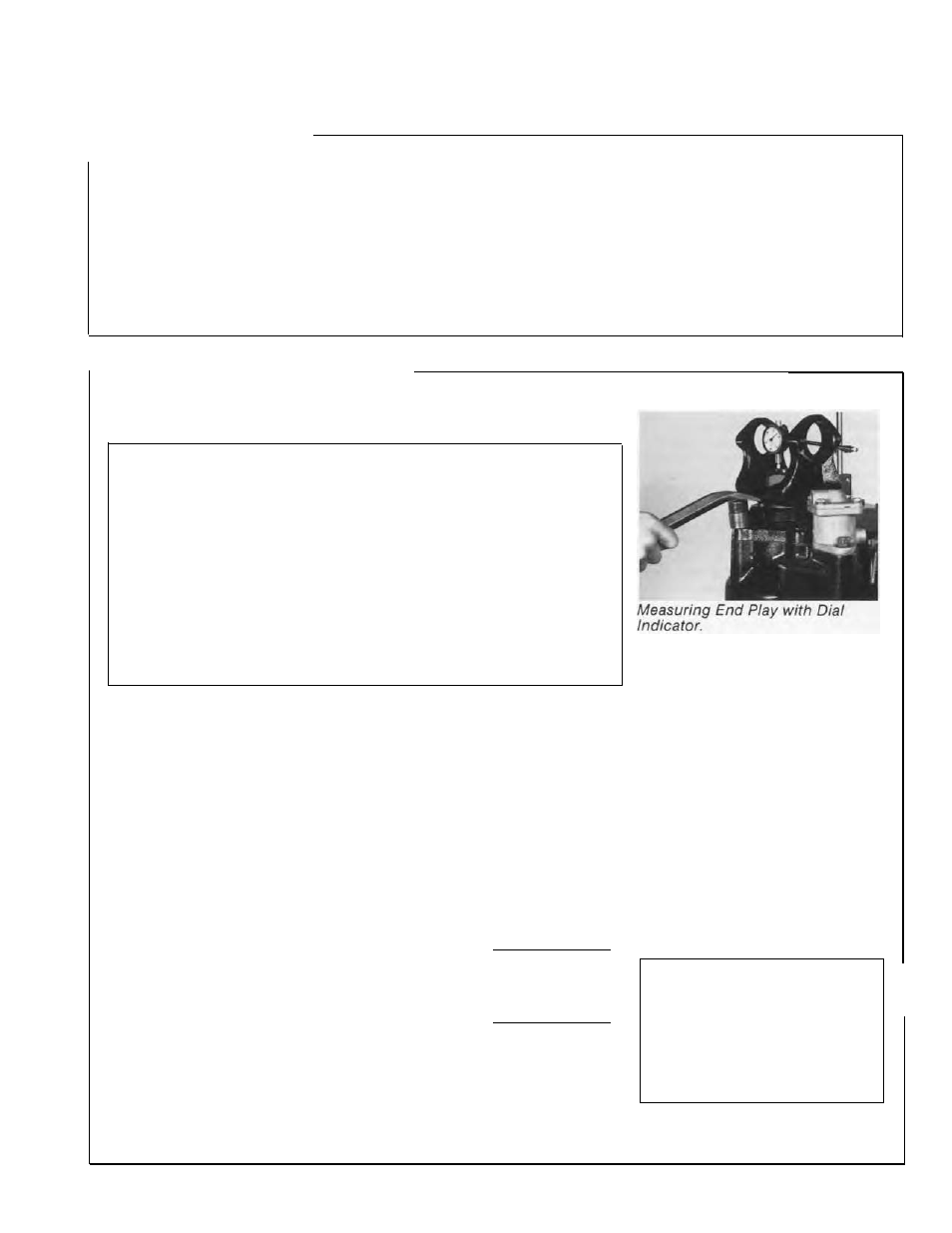

Measure and Adjust End Play

IMPORTANT:

In September 1988, Spicer added a Spring and a Thrust

Button between the input and output shafts. End play tolerances are the

same for axles with or without this Spring and Button. However, end play

measurement procedure is different than-described below. Refer to Service

Bulletin Supplement at back of this manual for procedure variances.

1.

With power divider assembled to differential carrier, measure end

pay with dial indicator positioned at yoke end of input shaft. Move

input shaft axially and measure end play. If end play is not correct (see

chart), adjust as follows.

2.

Remove input shaft nut, flat washer and yoke. Remove bearing cover

cap screws and lockwashers. Remove cover and shim pack.

3. To increase end play, add shims:

desired end play . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.003" to 0.007"

pleasured endplay (Step)....... . . . . . . . . . . . . . . . . 0.001" - 0.001"

Add shims to provide desired end play . . . . . . . . . . . . . 0.002" to 0.006"

4. To decrease end play, remove shims:

Measured endplay (Step 1l) . . . . . . . . . . . . . . . . . . . . . . . 0.015" - 0.015"

desired end play . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.003" to 0.007"

Remove shims to provide desired end play . . . . . . . . . 0.012" to 0.008"

5.

To reassemble input shaft, install the adjusted shim pack and bear-

ing cover. Install cap screws and lockwashers. Torque screws to 75-85

ft-lbs. (101-115 N.m).

NOTE:

If difficulty is experienced in achieving correct torque on the

input yoke nut, torque the nut with truck on the ground and axle shafts

installed.

6.

Install yoke, flat washer and nut.

Tighten nut snugly. Tap end of

input shaft lightly to seat bearings.

7.

Measure input shaft end play

with dial indicator. If end play is

still incorrect, repeat Steps 2

through 6.

8.

With end play correct, seal shim

pack to prevent lube Ieakage, then

torque input shaft nut and cover

cap screws (see chart).

NOTE:

When power divider has

been disassembled and reassem-

bled, it may be desirable to adjust

end play by measuring bearing

cover clearance and calculating

shim pack size. For procedures,

see page 42.

Torque Chart

Input

Shaft Nut

Ft-lbs.

N´m

1-5/8-18

780-960

1057-1301

*M42

X 1.5

840-1020

1140-1383

Bearing Cover

Cap Screw

1/2-13

75-85

101-115

(Grade 5)

*Metric Nut used on Axles produced after 7/1 /95

19