Disassemble drive pinion – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 45

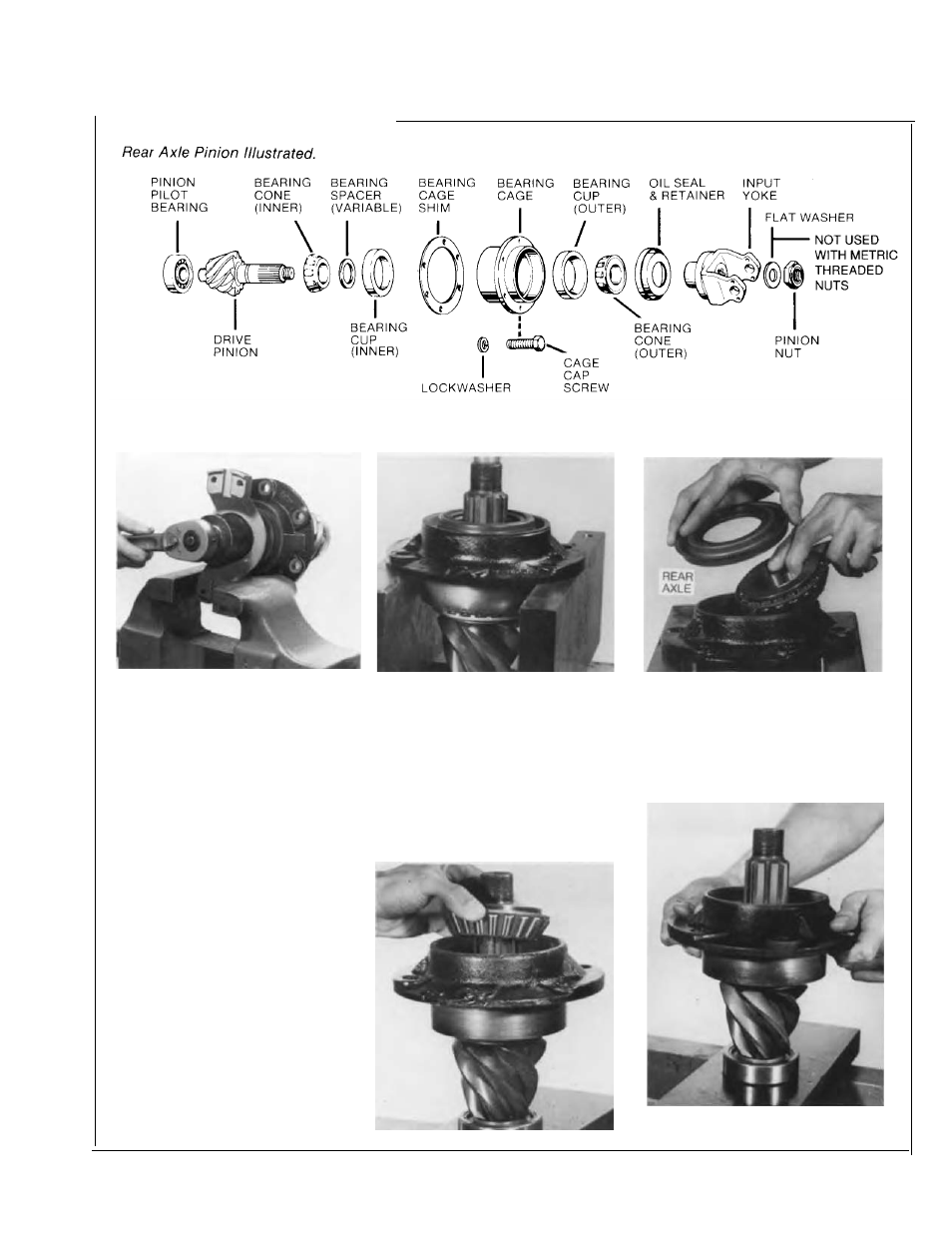

Disassemble Drive Pinion

NOTE:

Sicer drive axles may be equipped with either "slip-fit" or "press-fit" outer pinion bearings.

procedures are contained in this section for disassembly of both types.

IMPORTANT:

During the following

yoke removal procedure, the drive

pinion may fall out of bearings and

cage. Do not allow pinion to drop

on hard surface.

1. Rear Axle Pinion Yoke:

Remove yoke. If pinion nut was

not loosened during earlier disas-

sembly, clamp assembly in vise

jaws, use brass pads to prevent

damage.

2. Forward and Rear Axle Pinion

Bearing Cage:

For pinion with

"press-fit" bearing cone, support

cage and press pinion out of bear-

ing cage and bearing cone.

For pinion with "slip-fit" bearing

cone, the cage, outer bearing and

pinion can usually be disassem-

bled easily without a press. If

difficulty is experienced, use

a press.

Loosen and remove pinion nut

and flat washer.

NOTE:

Flat washers are not used

with metric threaded nuts. Metric nuts

went into production on 7-1-95.

Removing "Sllp-Fit" Outer Bearing

Cone (Rear Axle illustrated).

3. Rear Axle Pinion Oil Seal and

Outer Bearing Cone:

Remove oil

seal and bearing cone from cage.

Discard oil seal. Remove bearing

cups with suitable puller.

Removing Bearing Cage (Rear

Axle illustrated).

45