Install power divider on differential carrier – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 33

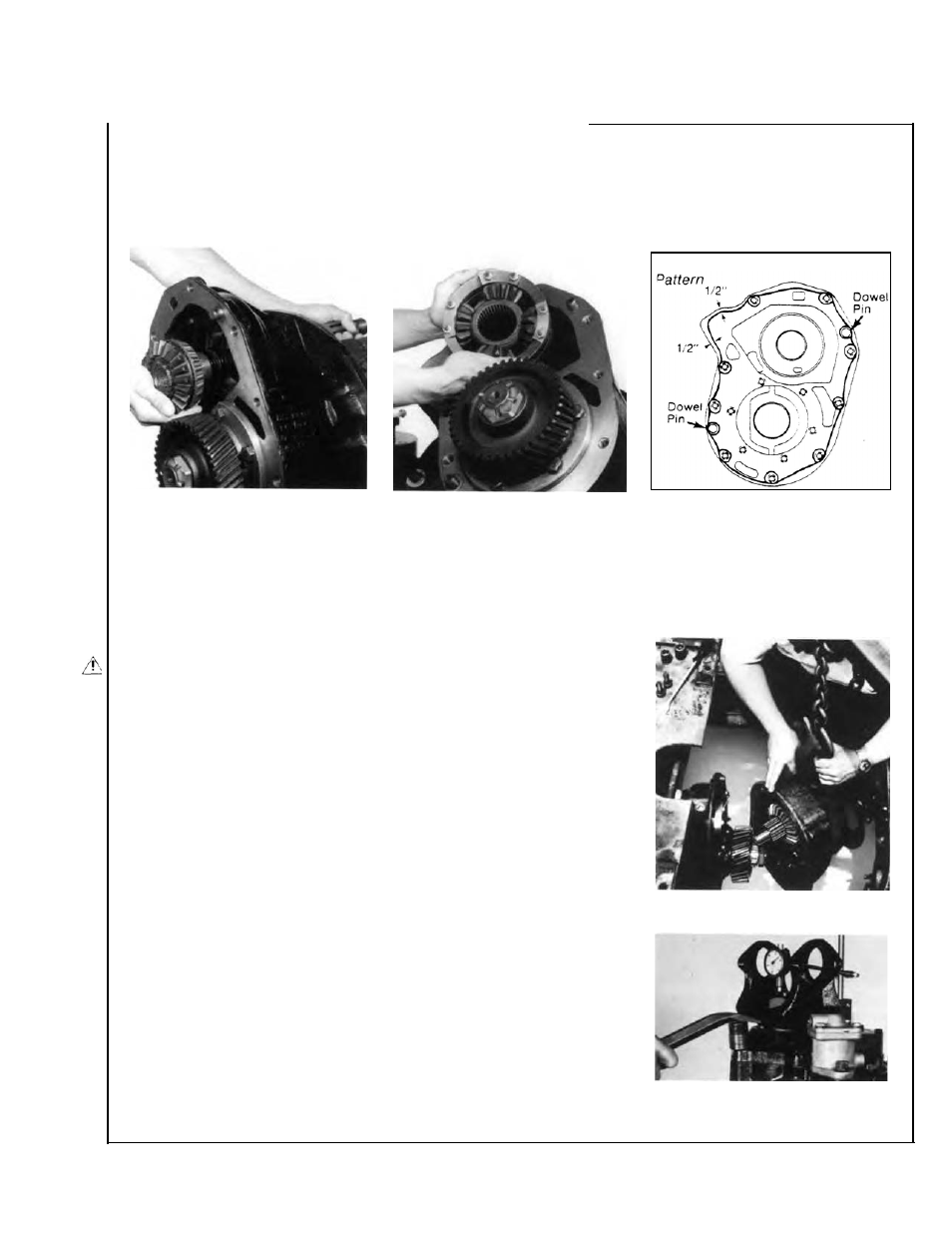

Install Power Divider on Differential Carrier

ïwith carrier assembled to axle housing)

NOTE:

Lubricate all parts before installation.

1. Axle Housing Covet and Output Shaft Bearing Parts.

If removed,

install these parts following instructions on page 31.

-.

Silicone Gasket Compound

2. Output Shaft.

If removed,

lubricate "O" rings, then install

shaft assembly in differential car-

rier and housing cover. Lubricate

seal lip. Make sure yoke is clean

and dry, then install yoke, flat

washer and self-locking nut.

Torque nut to 480-600 ft.-lbs.

(650-813 Nm),

NOTE:

Late Model Axles may be

equipped with a spring and thrust

button mounted in end of output

shaft. (see page 74).

3. Inter-axle Differential.

Install

this assembly on output shaft side

gear (with nuts facing away from

side gear).

4. Power Divider Assembly.

Use

silicone rubber gasket compound

on differential carrier mating sur-

face as shown in the illustration.

NOTE:

Compound will set in 20

minutes. Install power divider be-

fore compound sets or reapply.

CAUTION:

DURING INSTALLATION OF POWER DIVIDER, THE

INTER-AXLE DIFFERENTIAL MAY FALL FROM CARRIER. EXERT

CAUTION TO PREVENT DAMAGE OR INJURY.

5.

Make certain dowel pins are installed in carrier (see drawing above),

then install power divider assembly.

Use a transmission jack or a chain hoist and sling (see photo).

During installation, rotate input shaft to engage input shaft splines with

inter-axle differential. After installation, again rotate input shaft to check

for correct assembly. Output shaft should turn when input shaft is

rotated.

6.

Install power divider cover cap screws and lockwashers. On pump

models only, install socket-head cap screw in correct location (see

drawing on preceding page). Torque cap screw to 110-125 ft.-lbs.

(149-170 Nm).

7. Check and Adjust Input Shaft Play.

With power divider assembled

to differential carrier. Check end play with dial indicator. If necessary

adjust end play (see page 19 or Service Bulletin Supplement Page 74).

After input shaft end play is within specifications complete assembly

procedure follows:

8.

Connect drivelines. Connect lockout air line.

9.

Fill axle to proper lube level (see Lubrication Section).

IMPORTANT:

When axle has been disassembled or housing, gears, axle

shafts or wheel equipment replaced, check axle assembly for proper

differential action before operating vehicle. Wheels must rotate freely

and independently.

Installing Power

Divider Assembly

with Chain Hoist and Sling.

Measuring Input Shaft End Play

with Dial Indicator.

33