Differential carrier overhaul – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 50

Differential Carrier Overhaul

(Forward and Rear Axles)

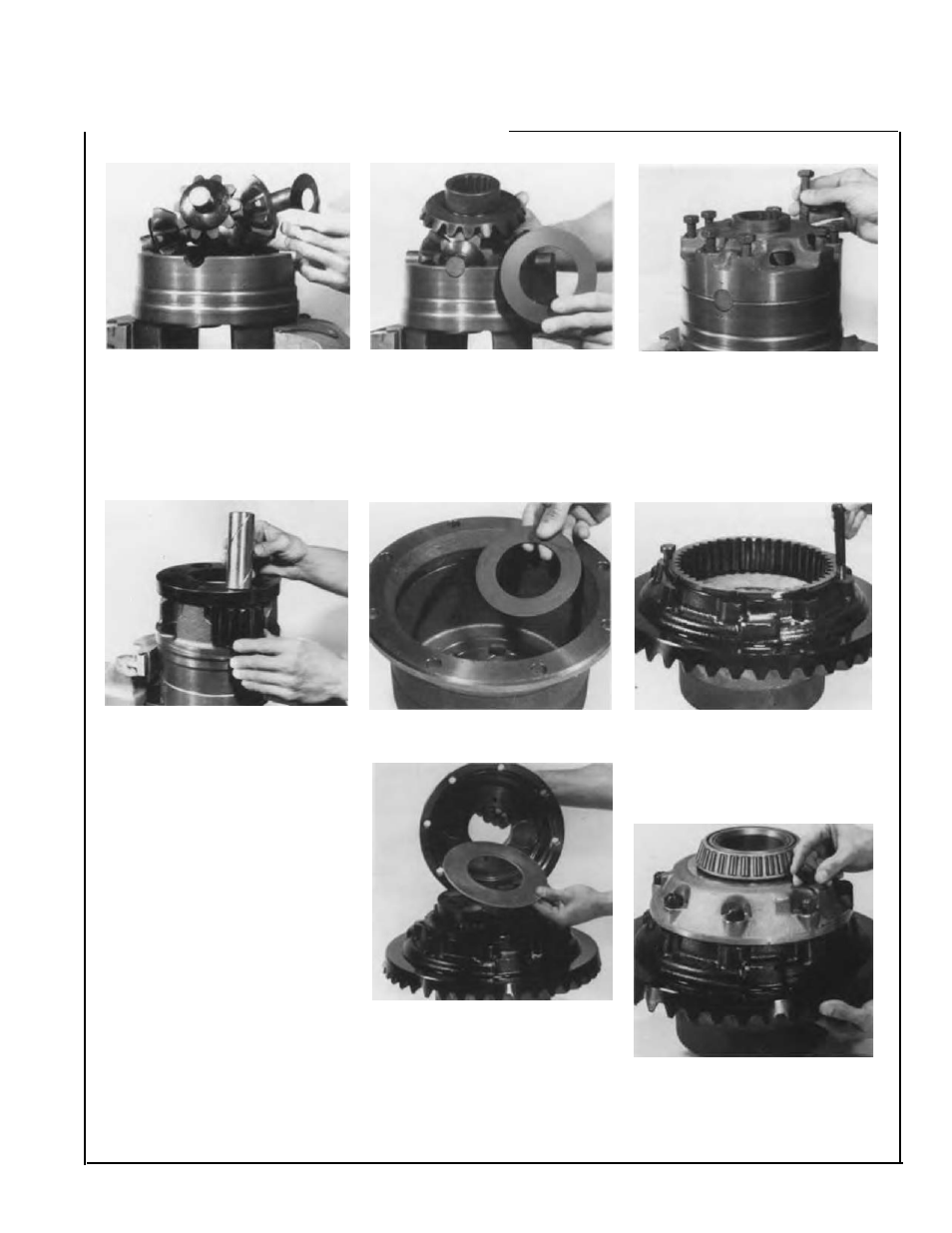

Assemble Wheel Differential (Cont'd)

4.

Assemble side pinions and

thrust washers on spider. Place this

assembly in differential case.

5.

Place side gear and thrust

washer in position on side pinions.

7.

Install idler pins and pinions.

8.

Place thrust washer in support

case.

10.

To install differential assembly,

place support case and ring gear

assembly on a bench or the floor.

Position case on its side. Carefully

lift and slide differential assembly

into case. Engage idler pinions with

ring gear teeth to complete the

installation.

NOTE:

During differential installa-

tion, be sure thrust washer stays in

its proper mounting position.

11.

Install thrust washer and small

support case over differential

assembly.

6.

Align punch marks and place

plain case on case (with pins). in-

stall cap screws and torque to

90-110 ft-lbs. (122-149 Nm).

NOTE:

Turn side gear hub to check

for free differential rotation. Rota-

tion may require up to 50 ft-lbs.

(65 Nm).

9.

During installation of ring gear,

temporarily use two bolts in mount-

ing holes to assure bolt hole align-

ment. Place ring gear on support

case (see photo), then remove the

two bolts.

12.

Carefully install ring gear bolts, making certain flat on bolt head is

seated against the outside diameter of the support case. Install nuts

and torque to 110-130 ft-lbs. (149-176 Nm).

NOTE:

Temporarily install sliding clutch (or sun gear) and check

planetary for free rotation.

I

5 0