Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 23

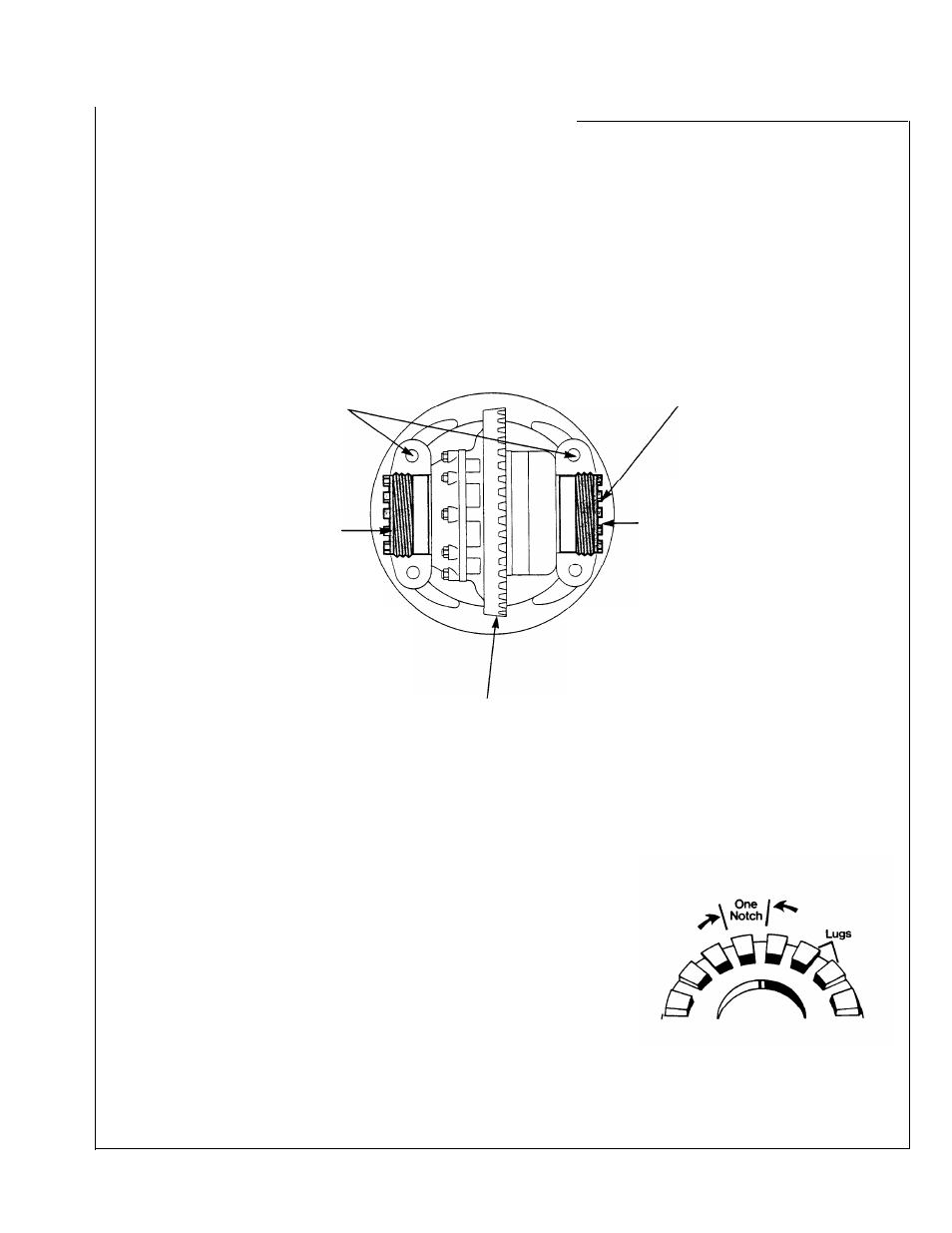

Differential Bearing Preload and Ring Gear

Backlash Adjustment

Correct differential bearing preload insures proper location of these

bearings under load and helps position the ring gear for proper gear

tooth contact.

(Follow procedures in numerical sequence.)

Adjust Diff. Bearing Preload

1.

Lubricate differential bearings.

NOTE:

Ring gear position for rear

3.

Loosen the bearing adjuster

IMPORTANT:

When installing

axle is illustrated.

on the same side as the ring gear

bearing caps and adjuster, exert

teeth until its first thread is

care not to cross threads.

visible. /

2.

Install adjusters and bearing

caps. Tighten bearing cap screws

/

finger-tight. If this is difficult,

use a hand wrench.

4.

Tighten the bearing adjuster

on the back-face side of the ring

gear until there is no backlash.

This can be tested by facing the

ring gear teeth and pushing the

gear away from the body while

gently rocking the gear from side

to side. There should be no free

movement.

Rotate the ring gear and check

for any point where the gear may

bind. If such a point exists,

loosen and retighten the back

side adjuster. Make all further

adjustments from the point of

tightest mesh.

Adjust Ring Gear Backlash

To

add

backlash: Loosen the

adjuster on the teeth side of the ring

gear several notches. Loosen the

opposite adjuster one notch.

Return to adjuster on teeth side of

the ring gear and tighten adjuster

until it contacts the bearing cup.

Continue tightening the same ad-

juster 2 or 3 notches. Recheck

backlash.

5.

At teeth side of ring gear,

tighten adjuster until it contacts

the bearing cup. Continue tighten-

ing adjuster two or three notches

and this will preload bearings and

provide backlash.

6.

Measure backlash with a dial indicator.

USED GEARING —

Reset to backlash recorded before disassembly.

NEW GEARING —

Backlash should be between 0.006” and 0.016”.

If backlash is incorrect, proceed as described below to readjust.

To

remove

backlash: Loosen the

adjuster on the teeth side of the ring

gear several notches. Tighten the

opposite adjuster one notch.

Return to adjuster on teeth side of

ring gear and tighten adjuster until it

contacts the bearing cup. Continue

tightening the same adjuster 2 or 3

notches. Recheck backlash.

Moving adjuster one notch is the

movement of the lead edge of one

adjuster lug to the lead edge of the

next lug past a preselected point.

23