Adjustments – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 22

Adjustments

Adjust Pinion Bearing Preload for Axles with

ñSlip-fitî Outer Pinion Bearings

1.

Lubricate bearings and assemble the

drive

pinion, bearings, and

pinion bearing cage as recommended in the assembly section of this

manual. Use the pinion bearing spacer removed from the axle during

disassembly. If the original spacer cannot be used, install the nominal

spacer recommended in the adjacent chart.

NOTE: Forward axle

pinion is equipped with helical gear. For easier

disassembly during bearing adjustment procedure, use a dummy yoke

(if available) in place of helical gear.

2.

Apply clamp load to the pinion bearings. Install the yoke (or helical

gear) and torque the nut to specification or use a press to simulate nut

torque by applying pressure to the assembly (see chart below).

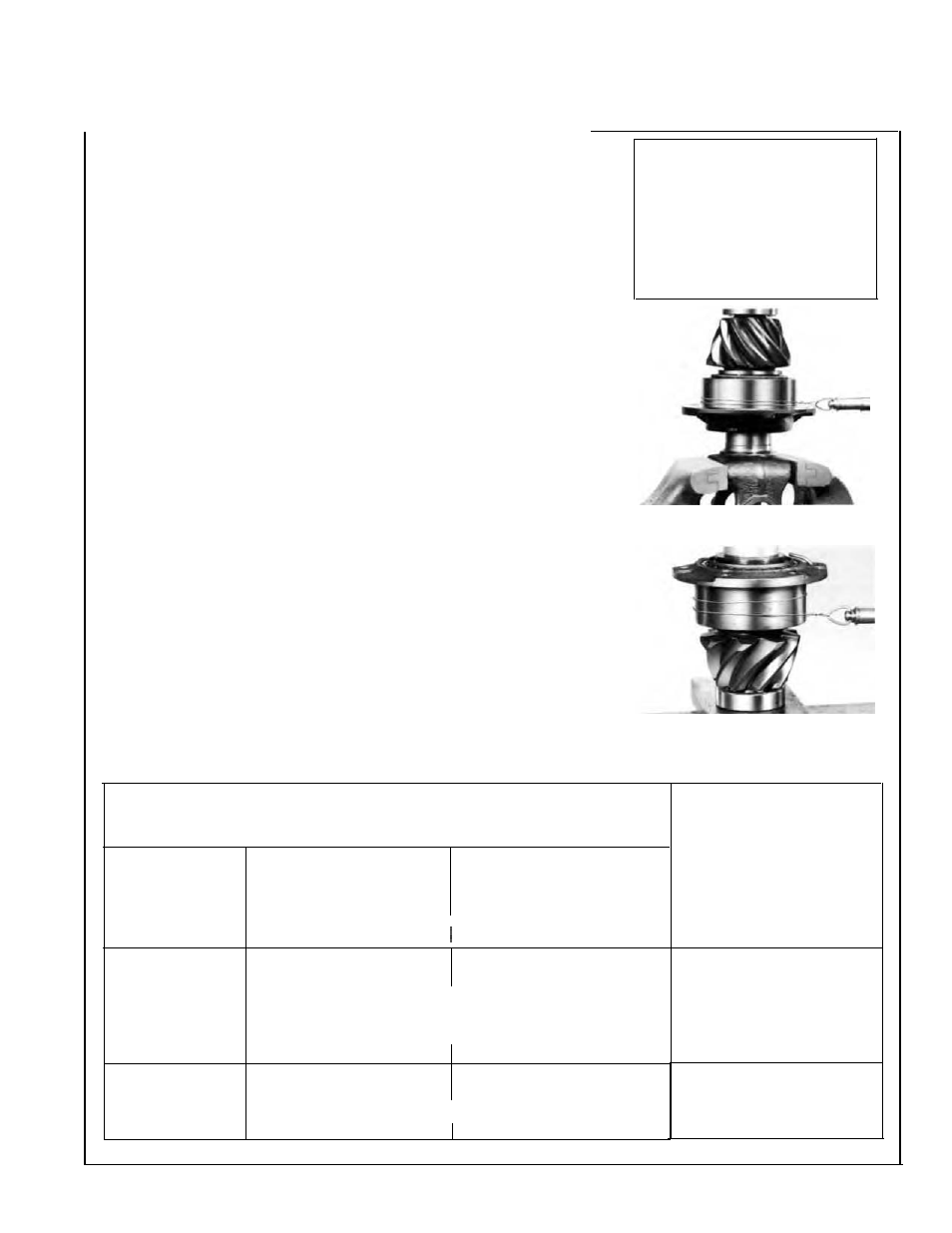

Vise Method -

If the yoke and nut are used, mount the assembly

in a vise, clamping yoke firmly.

Press Method -

If a press is used, position a sleeve or spacer so that

load is applied directly to the back-face of outer pinion bearing.

3.

Measure Pinion Bearing Preload - Use a spring scale to test the

assembly rolling torque. To use the spring scale, wrap a soft wire around

the bearing cage, attach the scale and pull. Preload is correct when

torque required to rotate the pinion bearing cage is from 15 to 35 inch

pounds. This specification is translated into spring scale readings in the

chart below.

4. Adjust Pinion Bearing Preload -

If necessary, adjust pinion bearing

preload. Disassemble the pinion bearing cage as recommended in this

manual and change the pinion bearing spacer. A thicker spacer will

decrease preload. A thinner spacer will increase preload.

IMPORTANT:

Use the correctly sized spacer. Do not use shim stock or

grind spacers. These practices can lead to loss of bearing preload and

gear or bearing failure.

Specifications for Final Pinion

Bearing Preload Test

("Press-fit" Outer Pinion Bearing)

Axle Models

Forward Axles

D340, 380(P),

400-P

D341, 381 (P),

401-P, 402(P),

451-P

Rear Axles

(all models)

Nominal Pinion

Bearing Spacers

Spacer Thickness

Axle Model

in. mm

Forward Axles

D340, 380(P), 400-P

D341, 381(P), 401-P,

0.638 16.205

402(P), 451-P

0.492 12.497

Rear Axles

(all models)

0.638 16.205

Measuring Bearing Preload with

Pinion in Vise.

Measuring Bearing Preload with

Pinion in Press.

Nut Torque

Press Loads

Ft-lbs. N.m

Tons

Metric Tons

SELF-LOCKING NUT

I

560-700

759-949

13.5-15.5 12.2-14.0

SELF-LOCKING NUT

780-960

1057-1301

17-19

15.4-17.2

SLOTTED NUT & ROLL PIN

840*

11 39*

17-19

15.4-17.2

METRIC NUT (After 7-1-95)

840-1020

1140-1383

17-19

15.4-17.2

560-700

759-949

14-15

12.7-13.6

METRIC NUT (After 7-1-95)

575-703

774-955

Spring Scale Reading

(without pinion seal)

(for 15-35 in-lbs. torque)

(1.7-4 N.m)

lbs.

kgs.

5-12

2.3-5.4

5-12

2.3-5.4

5-12

2.3-5.4

6-14

2.7-6.4

*Torque nut to 840 ft-lbs. (1.139 N´m), then continue tightening nut to align nut slot to nearest hole in pinion shank.

22