Air shift unit replacement, Air shift unit overhaul – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 70

Air Shift Unit Replacement

Remove Unit

Install Unit

Disconnect air line at shift unit

1. Lubricate

shift fork. Slide seal

3. When axle is installed in vehi-

cover. Remove nuts, flat washers

and spring assembly over fork and

cle, fill shift unit housing to level

and piston air-shift unit from differ-

seal on differential carrier studs.

of filler plug with SAE 10 oil or

ential carrier.

Shift axle into Low Range.

automatic transmission fluid (see

NOTE: When shift unit is removed,

2. Place shift unit on mounting

Lubrication on

following page).

provide container to catch oil that

studs and make certain shift fork

Coat threads of filler plug with

escapes from reservoir. Remove

actuating lever engages slot in shift

sealer and install plug.

shift fork seal and spring.

fork. Install flat washers and stud

4.

Connect air lines to shift unit

nuts. Tighten nuts to 55-61 ft-lbs.

cover.

I

(74-82 Nm).

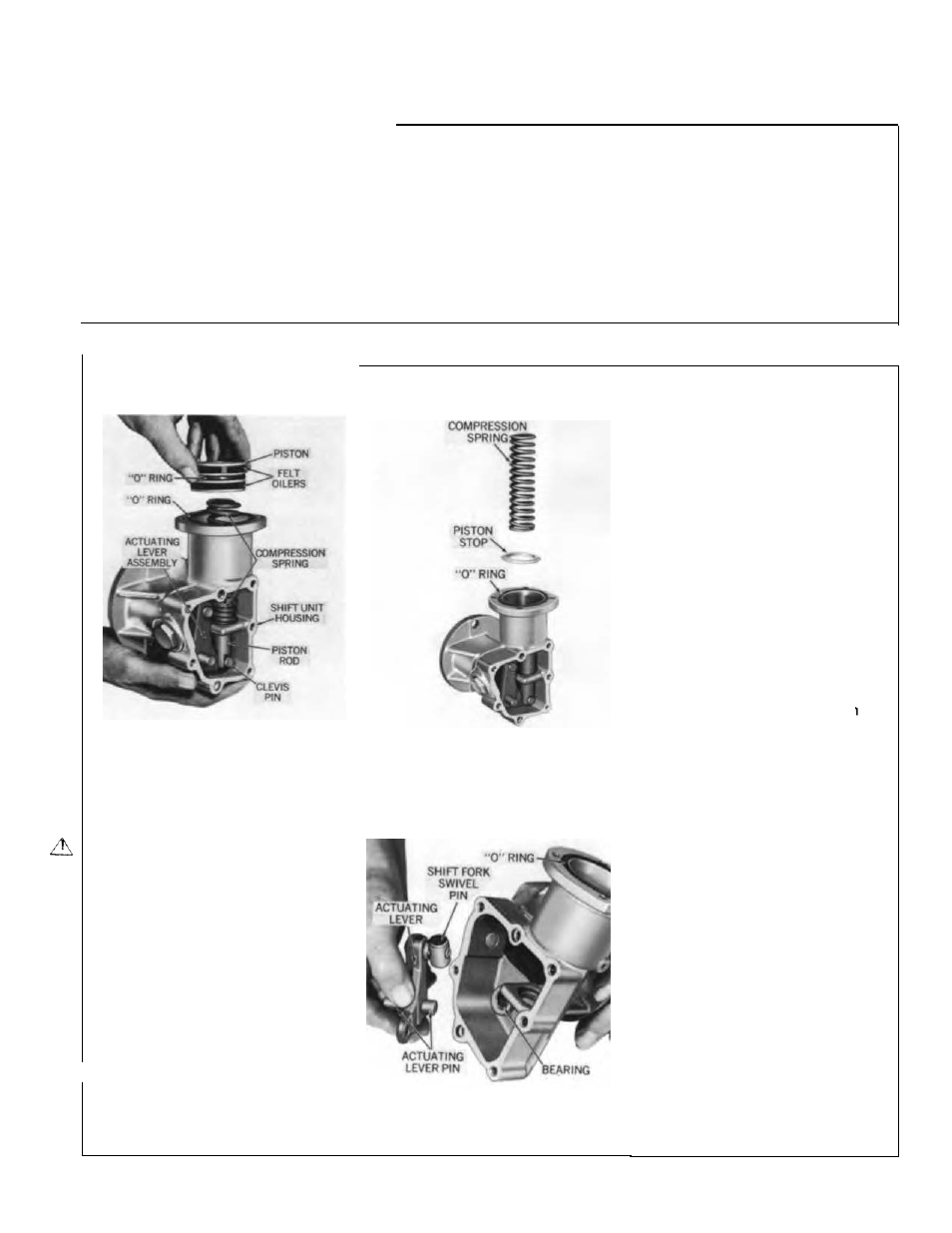

Air Shift Unit Overhaul

Disassemble Unit

1.

Remove cap screws, lock

washers, cover and gasket from

housing. Drain lubricant.

2.

Remove bolts, locknuts, cover

at piston end of housing.

Remove "O" ring.

CAUTION:

DURING THE

FOLLOWING PROCEDURE, THE

PISTON WILL POP OUT OF

HOUSING UNDER SPRING

PRESSURE. EXERCISE CAUTION

TO PREVENT POSSIBLE INJURY.

3.

Remove locknut, flat washer,

and piston from push rod.

Remove "O" ring and felt oilers

from piston.

4.

Remove compression spring

and piston stop from bore of shift

unit housing.

5. Remove clevis pin, then

remove

push rod from shift unit housing.

Remove "O" Ring from push rod.

6.

Remove actuating lever and pin

assembly from shift unit housing.

Do not disassemble actuating lever.

Parts Inspection

Shift Fork Seal

- Inspect shift fork

seal for defects and tight fit on

shift fork. A spring is used to

assure a closer fit of seal around

shift fork. If this spring is not

present on axle being serviced,

install one when reassembling unit.

"O" Rings, Felt Oilers and Gasket -

Replace "O" rings, felt oilers

and cover gasket when piston air-

shift unit is disassembled for repair.

Compression Spring -

Inspect

spring for distortion, cracks, or

other visual defects, Replace a

faulty spring.

Actuating Lever and Pins -

Inspect lever pins and bearings

for worn or grooved condition.

Inspect actuating lever and pus

rod for worn or elongated holes

at point where they are connected.

Replace faulty parts.

Piston

- inspect piston friction

surface for worn, grooved or

damaged condition which will

affect the piston movement in

cylinder. Replace a faulty piston.

71