Dual range axle shift systems, Description – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 60

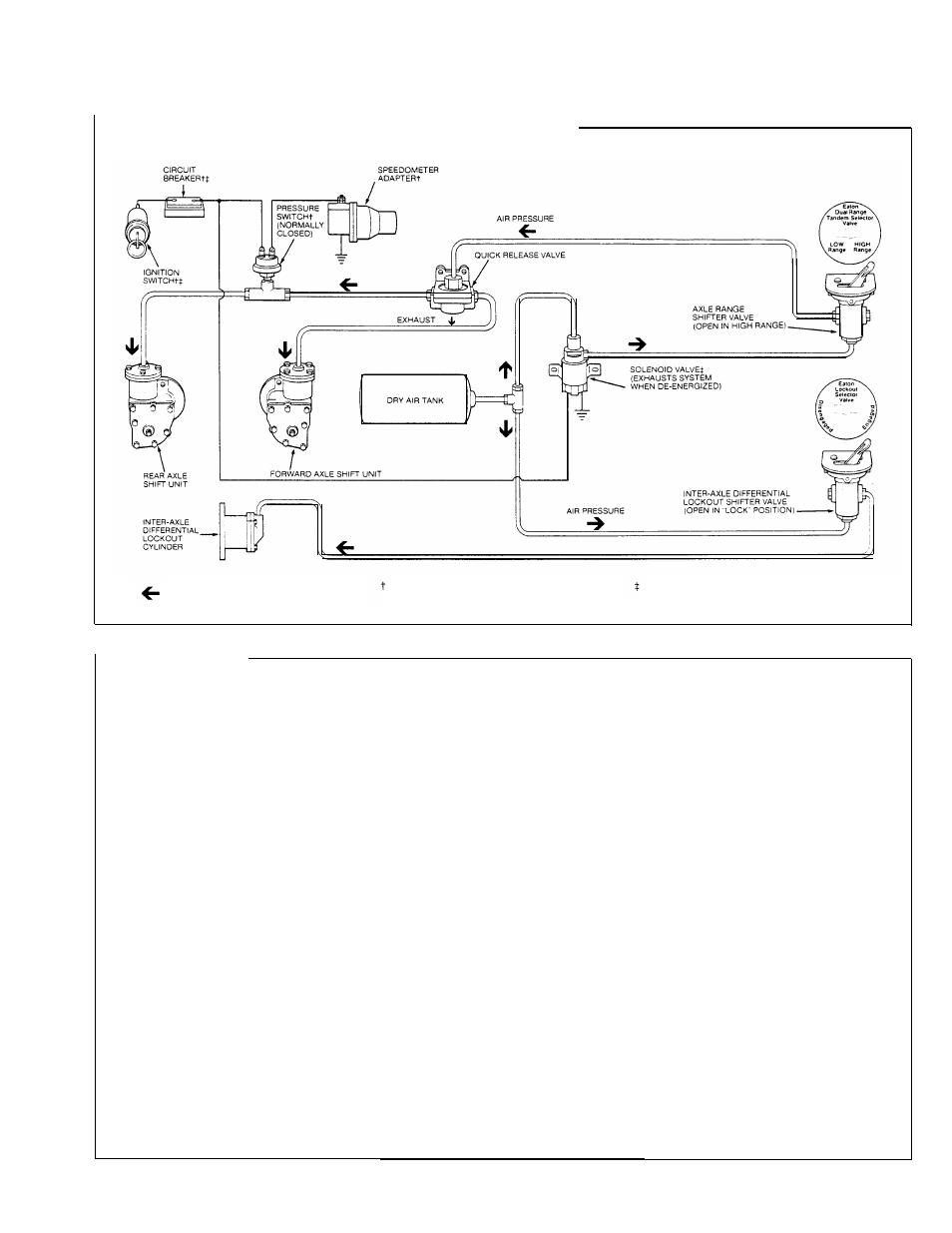

Dual Range Axle Shift Systems

Standard System for Axle Range Selection

and Inter-Ax/e Differential Lockout

(straight-air type)

Air pressure with axle in High Range,

Inter-Axle Differential Engaged.

Pressure switch and speedometer adapter

Solenold valve required for vehicles

required for vehicles with transmission

not equipped with automatic safety brakes.

drive speedometers.

Description

The standard dual range shift system

consists of:

1.

A manually-operated, air shifter

valve to change axle range.

2.

A quick release valve which

provides for fast release of air pres-

sure from the axle shift units.

3.

Two air shift units mounted on the

axles. These shift units are mechani-

cally connected to the axle shift forks

and sliding clutches which, in turn,

shift axles into Low or High Range.

For vehicles not equipped with auto-

matic safety brakes,

an ignition-

controlled solenoid valve exhausts

the system and downshifts the axles

when the ignition switch is turned off.

The electrical circuit is protected by a

circuit breaker.

For vehicles equipped with transmis-

sion-drive speedometers, the system

includes a speedometer adapter which

compensates speedometer readings

when axle is in Low Range. The

adapter is operated by an electrical

switch mounted on or near the quick-

release valve. The switch is normally-

closed and is opened by air pressure.

With axles in Low Range, the switch

is closed and the adapter is energized.

The adapter operates with a ratio

compatible with the axle Low Range

for proper speed readings. With axle

in High Range, the air lines are pres-

surized and the pressure switch is

open. The adapter now operates

with 1:1 ratio for proper speed

readings in High Range.

Axle Shift System Operation

High Range.

When shifter valve is

moved to the High position, the valve

is opened and air pressure is supplied

through the quick release valve to

both axle shift units. When driveline

torque is interrupted, the shift units

will shift both axles to High Range.

Low Range.

When shifter valve is

moved to the Low position, the valve

is closed. Air pressure in the shift

units is exhausted through the quick

release valve. When driveline torque

is interrupted, both axles are shifted

to Low Range and held in this position

by shift unit return springs.

Inter-Axle Diff. Lockout System

The lockout air shift system

consists of:

1.

A manually-operated air shifter

valve which controls engagement

or disengagement of the inter-axle

differential.

2.

A lockout cylinder which oper-

ates under air pressure. This cylin-

der is mechanically-connected to a

shift fork and sliding clutch. The

clutch engages or disengages a

differential helical-side gear to

“Lock” or “Unlock” the differential.

Lockout System Operation.

For

operation description, refer to the

following page.

61

.