Power divider overhaul, Assemble power divider (cont'd) – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 40

Power Divider Overhaul

Assemble Power Divider (Cont'd)

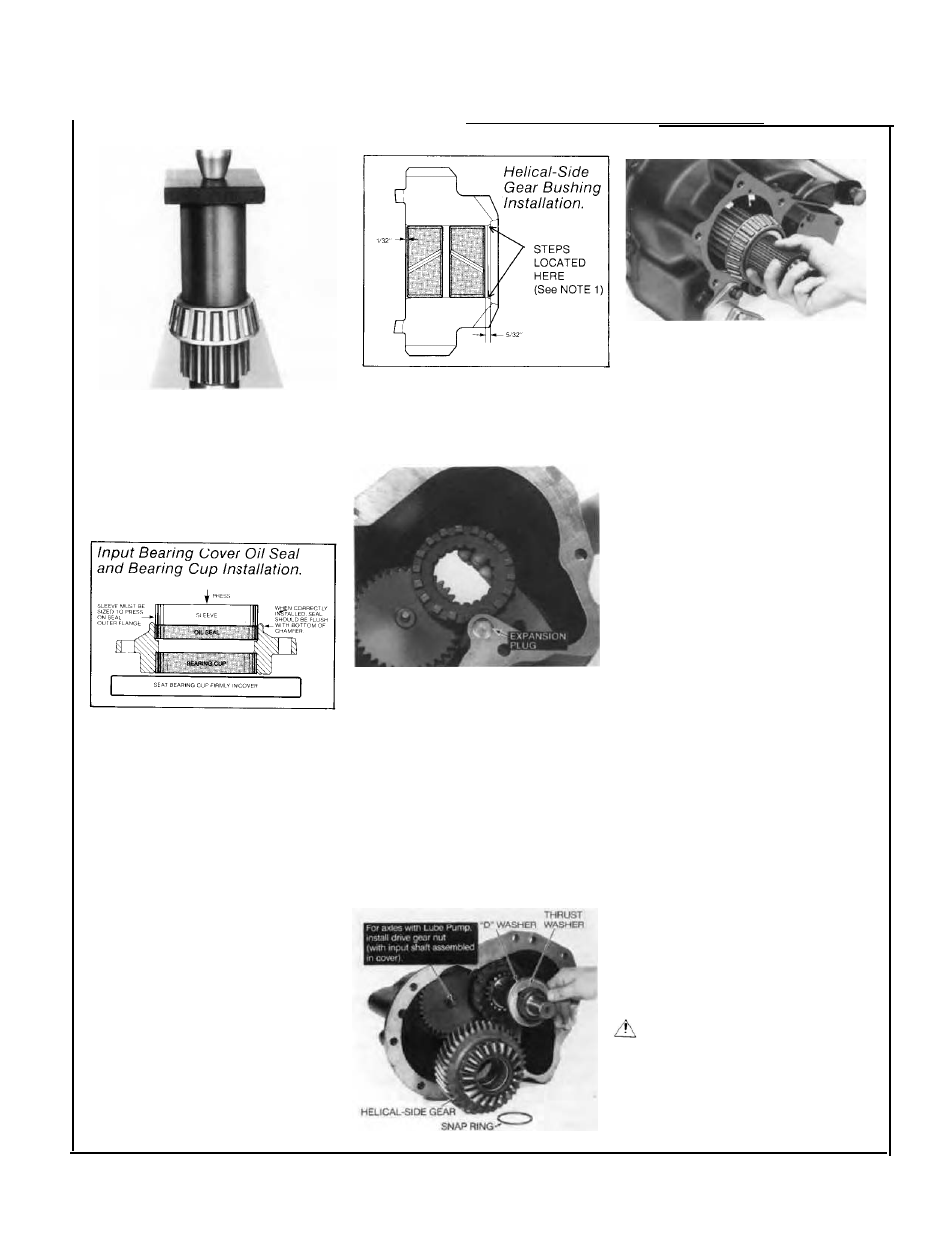

5.

Press bearing cone on input

shaft.

IMPORTANT:

To prevent bearing

damage, be careful to use sleeve

that only contacts the inner race

of bearing cone.

SEAL INSTALLATION

IMPORTANT:

Before installing

seal, refer to page 15 for service

information on SeaIs, Yokes &

Slingers.

6.

Press oil seal in cover using a

seal driver or suitable sleeve.

Press bearing cup in input

bearing cover.

IMPORTANT:

For correct cup

installation, use appropriate

sleeve. Take care to make sure

cup is not cocked and is firmly

seated all around.

NOTE 1:

Helical Gears made after

1/3/95 have a "step" at the end of

Inner Bore. Bushings must be in-

stalled from the Curvic Tooth side of

the Helical Gear inward towards this

step. Press bushing flush against

the shoulder of the step.

7.

Install bronze bushings in

helical-side gear.

8. NOTE:

Check expansion plug in

power divider cover (see photo

above) to make sure it is in place

and firmly seated. If loose, seat by

tapping with a hammer. Replace

plug if necessary.

Assemble lockout shift fork and

sliding clutch with clutch teeth

facing the helical-side gear, then

install this assembly in power

divider cover.

NOTE:

At this point in reassembly,

assemble and install lockout (see

Shift System Section).

9.

Slide input shaft and bearing

assembly into power divider cover

from the front side. Engage shaft

splines in lockout clutch.

Install bearing spacer on input

shaft (used only on D340, 380,

380-P, 400-P). Temporarily install

input bearing cover assembly, cap

screws and lockwashers.

NOTE:

Do not install any shims

under bearing cover at this time.

Correct shim pack will be deter-

mined after the power divider is

installed on differential carrier

(Refer to "Adjust Input Shaft End

play" page 42).

IMPORTANT: For Axles with

Spring and Thrust Button between

input shaft and output shaft:

For

preliminary adjustment of input

shaft end play, install a 0.045"

(0.024 mm) shim pack under

bearing cover (see Service

Bulletin Supplement, page 74).

Tighten bearing cover cap screws

finger-tight. Install input yoke, flat

washer and nut. Temporarily

tighten nut snugly.

10. lMPORTANT - Axles with

Lube Pump:

Install and tighten

lube pump drive gear locknut,

holding input shaft to secure gear.

Torque nut to 35-45 ft-lbs,

(47-61 Nm).

11.

Slide "D" washer over input

shaft up to base of sliding clutch

,.

splines.

NOTE:

Make sure flat part of

washer inside diameter engages

shaft properly.

Install bronze washer, Install

helical gear. Secure with snap ring.

WARNING:

SNAP RING IS

SPRING STEEL AND MAY POP

OFF. WEAR SAFETY GLASSES

WHEN INSTALLING.

12.

Install power divider cover

assembly on differential carrier

(see page 41).

40