Differential carrier overhaul, Rear axle - install pinion, Rear axle - install differential in carrier – Spicer Tandem Drive Axle Dual Range & Double Planetary 34,000-45,000 lbs User Manual

Page 56

Differential Carrier Overhaul

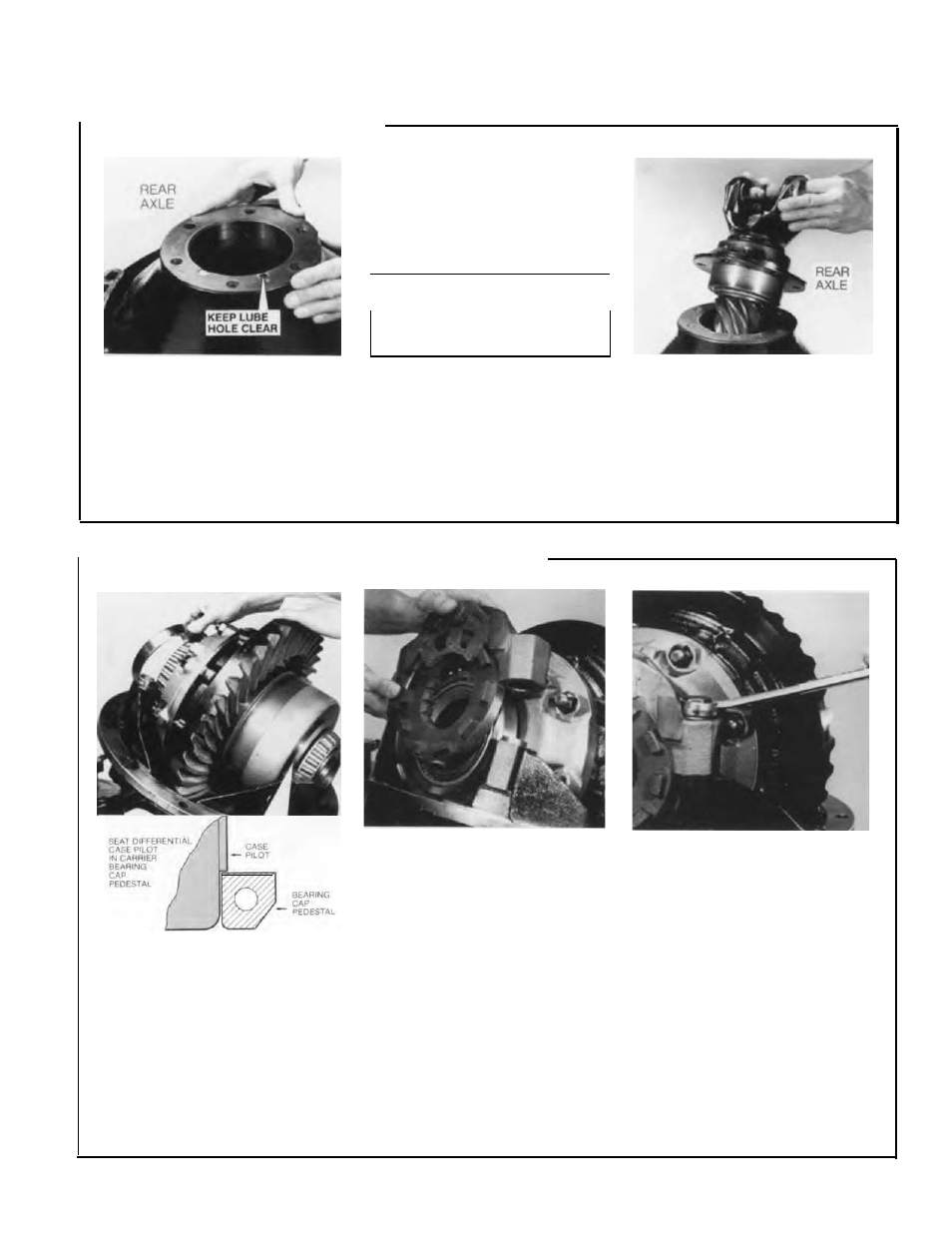

Rear Axle - Install Pinion

1.

Place

shim pack on carrier

making

sure

lube hole is clear (see

photo).

NOTE:

If the gear set is to be re-

used, use same quantity and size

shims removed during disassem-

bly. If a new gear set is to be in-

stalled, install a nominal shim pack

(see chart).

I

Nominal Shim Pack

I

in

mm

0.023

0.584

2.

Install drive pinion assembly.

NOTE: Make certain lube holes

in carrier, shims and cage are

aligned. install bearing cage cap

screws and lockwashers. Torque

cap screws to 110-125 ft-lbs.

(149-170 Nm).

Rear Axle - Install Differential in Carrier

NOTE:

Lubricate bearings during

the following assembly procedure:

1.

Place ring gear and differential

assembly in carrier. Insure that

ring gear and drive pinion mesh

properly.

During installation, tilt carrier to

allow support case pilot to rest in

carrier bore, then install bearing

cup as shown in photo.

Also

install bearing cup on opposite

side of differential.

2.

If the same gear set is used,

install the assembled bearing cap,

adjuster and lock on the backface

side of the ring gear. Otherwise

install adjuster and cap separately.

NOTE: When installing cap, it may

be necessary to tap it lightly with a

hammer.

Be

sure cap is fully

seated and threads are aligned

properly, If trouble is encountered,

check for cross-threading of bear-

ing adjuster and carrier threads.

On teeth side of ring gear, install

the other adjuster and bearing

cap, observing same precautions

to avoid cross-threading.

3.

Install and tighten bearing cap

screws finger-tight. If this is diffi-

cult, use hand wrench.

NOTE:

The assembly is now ready

for adjustment of differential bear-

ing preloan, ring gear backlash

and gear tooth contact (see page

57).

56